ACS 6000 – The world’s most successful MV multidrive

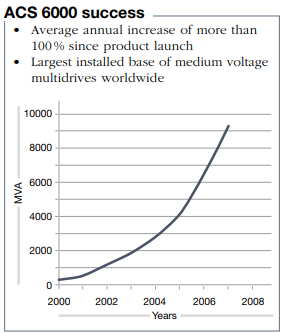

ABB’s ACS 6000 medium voltage drive provides the optimum solution for applications where high power and maximum reliability is required. Since its introduction, the ACS 6000 has gained an excellent reputation for high quality and reliability. As a result ABB has worldwide the largest installed base of medium voltage multidrives incorporating the latest technology

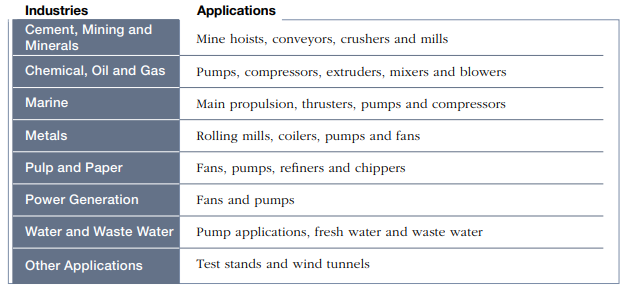

ABB’s ACS 6000 is a modular drive designed for the most demanding single-motor or multi-motor applications. The optimum configuration for each application is reached by combining the modules with minimum engineering effort resulting in lower investment costs and a smaller footprint. It is available with five sizes of inverter modules (3, 5, 7, 9 and 11 MVA). Several motors can be linked to the ACS 6000 via the common DC bus, enabling multi-machine operation with only one multidrive converter. A multidrive, common DC bus converter principle offers a solution with optimum efficiency. The ACS 6000 medium voltage drive can be used in a wide range of industries

Fields of application

Key features

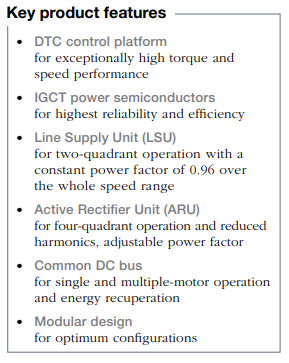

The ACS 6000 medium voltage drive for speed and torque control of 3 – 27 MW induction or synchronous motors is a member of the ABB AC drives product family. It offers a number of unique key features.

Powerful performance Fast and accurate process control in combination with low energy consumption results in top performance. The motor control platform of the ACS 6000 is based on ABB’s award-winning Direct Torque Control (DTC) technology. DTC provides the highest torque and speed performance ever achieved in medium voltage drives. As a result, control of the drive is immediate and smooth under all conditions. High efficiency and reliability The ACS 6000 uses a revolutionary power semiconductor switching device known as IGCT (Integrated Gate Commutated Thyristor) researched and designed by ABB. The use of IGCTs results in a less complex, more efficient and reliable high-power medium voltage drive, minimizing operating and maintenance costs

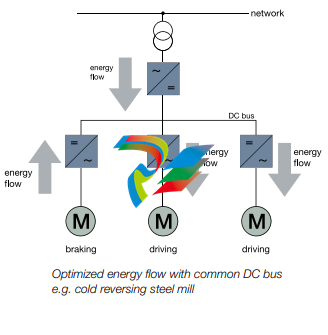

High availability Maximum reliability and short repair time results in a drive with high availability. Optimized energy flow The common DC bus allows several motors to be connected to the same DC bus, providing an optimized energy flow. The braking energy generated in one motor can be transferred to other inverters via the common DC bus without power consumption from the supply network. Due to the near unity power factor throughout the whole speed range the energy efficiency is optimal.

ACS 6000 advantages

• High power and maximum reliability

• Smooth torque over the entire speed range

• Applications operate at optimum efficiency

• Compact and high power density

• Low noise and vibration levels

• Minimized energy consumption with common DC bus

• Regeneration of rotating energy

Flexible Optimum configuration The modular design of the ACS 6000 allows the optimum configuration of any drive system. Each configuration, consisting of well-proven and certified modules, exactly fits the customer’s requirements

Smooth system integration The ACS 6000 integrates easily into the industrial environment because it can be optimally configured for single-motor and multi-motor applications without additional control equipment. The high power density and compact design and the drive’s communication abilities minimize the overall installation and operational costs

The drive can be connected to the network through one or several transformers depending on power and harmonics requirements. Even a transformerless solution is available for certain applications

ACS 6000 water-cooled

Technology highlights Reliability has been the main guiding principle of the research and development activities for ABB’s medium voltage AC drives.

Part count The fewer the parts the higher the reliability. ABB uses high power semiconductor switching devices and a topology that brings down the part count to a minimum. This results in a reliable, compact and service-friendly drive. Fuseless design The ACS 6000 medium voltage drive is designed to operate safely without fuses, resulting in less spare parts and better overall reliability. This allows fast startup after safety interruptions. Encoderless Encoders are known to cause failures due to their exposed position on the motor. ABB’s ACS 6000 medium voltage drive can operate without encoder, thereby reducing maintenance costs and ensuring high levels of availability. IGCT switching devices ABB has developed a high power semiconductor called IGCT (Integrated Gate Commutated Thyristor) to allow the use of modern control algorithms, which can eliminate harmonics, improve dynamic response time and maintain, or even control, the power factor. Low losses The inherently low total losses of the IGCT require low cooling capacity and small cooling equipment.

Control The ACS drive control platform is based on ABB’s award-winning Direct Torque Control (DTC), resulting in the highest torque and speed performance as well as lowest losses ever achieved in medium voltage drives. Control of the drive is immediate and smooth under all conditions and the audible noise in the motor is considerably reduced. What is Direct Torque Control? DTC is a revolutionary motor control method for AC drives that allows accurate control of both motor speed and torque without pulse encoder feedback from the motor shaft. In DTC, stator flux and torque are used as primary control variables. The motor state calculations are updated 40,000 times a second (i.e. every 25 µs) in the advanced motor software model by the high-speed digital signal processor. Due to the continuous updating of the motor state and the comparison of the actual values to the reference values, every single switching in the inverter is determined separately. DTC ensures the absolute lowest losses by switching the power semiconductors only when necessary. Fast response to mains fluctuations and process side changes The exceptionally fast torque step response of the ACS 6000 means that it can respond to process and mains changes extremely fast. This enables easy handling of power-loss situations and sudden load changes.

Common DC bus The ACS 6000 modularity is based on the common DC bus converter principle, where several motors (synchronous and induction) can be connected to the same DC bus. With five sizes of inverter modules available (3, 5, 7, 9 and 11 MVA), the optimum configuration for a specific application can be reached by combining the modules with minimum engineering effort. By linking the modules in parallel, the power can be increased to 27 MVA. Multidrive topologies with a common DC bus offer a solution with optimum efficiency. Energy regenerated from one section in braking mode can be directly used by another section via the DC bus without power consumption from the supply network. ACS 6000 modules Active Rectifier Unit (ARU) , Inverter Unit (INU) The Active Rectifier Unit (ARU) rectifies the AC line voltage and charges the DC link capacitors whereas the Inverter Unit (INU) inverts the DC voltage to the AC motor voltage. The layout and equipment of the INU and the ARU are identical. They are self-commutated, 6-pulse, 3-level voltage source inverters, incorporating IGCT technology for a reliable, fuseless operation with a minimum number of drive components. The ARU allows four-quadrant operation for regenerative braking, which reduces the overall energy consumption. It controls the power factor to unity in the whole operating range even at very low speeds. Optionally the ARU can be dimensioned to compensate reactive power generated by other loads connected to the same network.

ACS 6000 for induction or synchronous motors ACS 6000 for induction motors Squirrel cage induction motors are the workhorses of the industry due to their versatility, reliability and simplicity. ABB’s broad range of medium voltage AC induction motors includes ribbed cast iron fan cooled motors and modular type welded frame motors. The ACS 6000 is typically used with induction motors for applications such as pumps, fans, compressors, conveyors, hoists, mills, crushers and propulsion systems.

ACS 6000 for synchronous motors Synchronous motors are typically considered for higher power ratings (e.g. above 8 MW to more than 100 MW). In addition to their high power capabilities, synchronous motors offer a wide field weakening range as well as the benefits of high efficiency and high performance. The ACS 6000 synchronous drive is ideal for applications which require dynamic response and high torque, such as rolling mills and mine hoists and for high power applications, such as marine propulsion drives. For special applications (e.g. low speed pumps) the ACS 6000 can be used with permanent magnet motors.

System integration The ACS 6000 can either be installed to control just one motor, or to control several motors with comprehensive control features, minimizing overall installation and operational costs. The drive can be supplied by one or several transformers depending on power and harmonics requirements. Even a transformerless solution is available for certain applications. The ACS 6000 medium voltage drive with its modular concept allows optimum integration into the customer’s industrial environment.

• Low network harmonics • High power factor in the whole operating range • Optional reactive power (VAr) compensation • Small footprint • Fast commissioning • EMC compliant

Smooth integration into existing systems Commissioning The ACS 6000 is easy to commission. In its multidrive configuration, the ACS 6000 is much faster to commission than the equivalent number of single drives.

Control system ABB offers an open communication strategy enabling connection to a PLC (Programmable Logic Controller) or a DCS (Distributed Control System). Fieldbus connectivity with a wide variety of protocols is available. The ACS 6000 product family platform offers the possibility to monitor the transformers as well as the motors with the drive’s control system.

Applicable standards The ACS 6000 meets the IEEE 519-1992 and IEC 61000-2-4 specifications for voltage and current harmonic distortion for virtually all installations. This eliminates the need for expensive harmonic filters and protects other electrical equipment from harmonic disturbances. The ACS 6000 meets EN (IEC), CE, UL* , cUL* and other standards to ensure smooth system integration worldwide. * on request

The ACS 6000 allows smooth and simple system integration into the customer’s industrial environment.

Open control system ABB offers an open communication strategy, enabling connection to higher-level process controllers. The ACS 6000 can be installed with all major fieldbus adapters for smooth integration, monitoring and controlling of different processes, according to customer requirements. IndustrialIT ABB’s IndustrialIT means increased standardization and seamless interaction of different ABB products. The ACS 6000 bears the IndustrialIT Enabled symbol, a special mark indicating that the drive can be easily integrated into the IndustrialIT architecture in a ‘plug & produce’ manner.

Leave a comment

Your email address will not be published. Required fields are marked *