Ungrounded Distribution Systems

ATTENTION: PowerFlex 40 drives contain protective MOVs that are

referenced to ground. These devices must be disconnected if the drive is

installed on an ungrounded or resistive grounded distribution system.

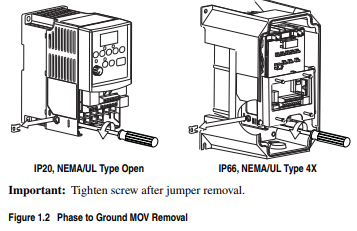

Disconnecting MOVs

To prevent drive damage, the MOVs connected to ground shall be

disconnected if the drive is installed on an ungrounded distribution

system where the line-to-ground voltages on any phase could exceed

125% of the nominal line-to-line voltage. To disconnect these devices,

remove the jumper shown in the Figures 1.1 and 1.2.

1. Turn the screw counterclockwise to loosen.

2. Pull the jumper completely out of the drive chassis.

3. Tighten the screw to keep it in place.

Figure 1.1 Jumper Location (Typical)

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. Safety Guidelines for the Application, Installation

and Maintenance of Solid State Controls (Publication SGI-1.1 available from your

local Rockwell Automation sales office or online at http://

www.rockwellautomation.com/literature) describes some important differences

between solid state equipment and hard-wired electromechanical devices. Because

of this difference, and also because of the wide variety of uses for solid state

equipment, all persons responsible for applying this equipment must satisfy

themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or

consequential damages resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with any

particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of

information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written

permission of Rockwell Automation, Inc. is prohibited.

Throughout this manual, when necessary we use notes to make you aware of safety

considerations

Allen-Bradley, Rockwell Automation, and PowerFlex are registered trademarks of Rockwell Automation, Inc. DriveExplorer, DriveExecutive, and SCANport are trademarks of Rockwell Automation, Inc. PLC is a registered trademark of Rockwell Automation, Inc

The information below summarizes the changes to the PowerFlex 40 User Manual since the August 2008 release.

Description of New or Updated Information Page(s)

Minimum Enclosure Volume column and new footnotes added. 1-9, A-2

Drive, Fuse & Circuit Breaker Ratings topic updated. A-1

Electronic Motor Overload Protection description updated. A-4

The information below summarizes the changes to the PowerFlex 40

User Manual since the April 2008 release.

Manual Updates

Description of New or Updated Information Page(s)

Description of A056 revised. 3-17

Description of A059/A062 revised. 3-19

Fault description for F3 revised. 4-3

A table row for electrical specifications added. A-4

Graphic for the “Network Wiring” section revised. C-1

Second last paragraph in the “Network Wiring” section revised. C-2

Text in the “Writing (06) Logic Command Data” section revised. C-4

Frequency source for logic command 001 of bits 14, 13, and 12 corrected. C-4

Text in the “Writing (06) Reference” section revised. C-5

Parameter Updates

The following parameters have been updated with firmware version 6.xx.

Parameter Number Description Page

[Relay Out Sel] A055 Function of option 20, ParamControl,

changed.

Option 24, MsgControl, added.

3-16

[Relay Out Sel] A058, A061 Function of option 20, ParamControl,

changed.

Option 24, MsgControl, added.

3-18

The information below summarizes the changes to the PowerFlex 40

User Manual since the January 2007 release.

Manual Updates

Description of New or Updated Information Page(s)

Input description and attention text for Multiple Digital Input Connection

example corrected.

1-22

New method of changing speed reference for IP66, NEMA/UL Type 4X rated

drives described.

2-2

Description for Up Arrow and Down Arrow keys revised. 2-4

Fault description for F3 revised. 4-3

Graphic for the “Network Wiring” section revised. C-1

Descriptions for bits 6, 7, and 15 of register address 8192 (Logic Command)

updated.

C-4

New information on reading register address 8192 added. C-4

New information on reading register address 8193 added. C-5

Graphic for the “Connecting an RS-485 Network” section corrected. D-4

New method for inverting sign of PID error added.

New Parameter

The following parameter has been added with firmware version 5.xx.

Parameter Updates

The following parameters have been updated with firmware version 5.xx.

Description of New or Updated Information Page(s)

Input description and attention text for Multiple Digital Input Connection

example corrected.

1-22

New method of changing speed reference for IP66, NEMA/UL Type 4X rated

drives described.

2-2

Description for Up Arrow and Down Arrow keys revised. 2-4

Fault description for F3 revised. 4-3

Graphic for the “Network Wiring” section revised. C-1

Descriptions for bits 6, 7, and 15 of register address 8192 (Logic Command)

updated.

C-4

New information on reading register address 8192 added. C-4

New information on reading register address 8193 added. C-5

Graphic for the “Connecting an RS-485 Network” section corrected. D-4

New method for inverting sign of PID error added. F-6

Parameter Number Description Page

[PID Invert Error] A167 New 3-44

Parameter Number Description Page

[Control Source] d012 Options 7 and 8 added. 3-5

[Start Source] P036 Description revised for option 6. 3-10

[Relay Out Sel] A055 Description revised for option 20. 3-16

[Relay Out Level] A056 Description revised. 3-17

[Opto Outx Sel] A058, A061 Description revised for option 20. 3-18

[Opto Outx Level] A059, A062 Description revised. 3-19

[Internal Freq] A069 Default value for IP66, NEMA/

UL Type 4X drives is 0.0 Hz.

Default value for IP20 rated drives is

60.0 Hz.

3-22

[PID Trim Hi] A130 Description revised. 3-38

[PID Trim Lo] A131 Description revised. 3-38

ATTENTION: The drive contains high voltage capacitors which take

time to discharge after removal of mains supply. Before working on

drive, ensure isolation of mains supply from line inputs [R, S, T (L1,

L2, L3)]. Wait three minutes for capacitors to discharge to safe voltage

levels. Failure to do so may result in personal injury or death.

Darkened display LEDs is not an indication that capacitors have

discharged to safe voltage levels.

!

ATTENTION: Only qualified personnel familiar with adjustable

frequency AC drives and associated machinery should plan or

implement the installation, start-up and subsequent maintenance of the

system. Failure to comply may result in personal injury and/or

equipment damage.

!

ATTENTION: This drive contains ESD (Electrostatic Discharge)

sensitive parts and assemblies. Static control precautions are required

when installing, testing, servicing or repairing this assembly.

Component damage may result if ESD control procedures are not

followed. If you are not familiar with static control procedures,

reference A-B publication 8000-4.5.2, “Guarding Against Electrostatic

Damage” or any other applicable ESD protection handbook.

!

ATTENTION: An incorrectly applied or installed drive can result in

component damage or a reduction in product life. Wiring or application

errors, such as, undersizing the motor, incorrect or inadequate AC

supply, or excessive ambient temperatures may result in malfunction of

the system.

!

ATTENTION: The bus regulator function is extremely useful for

preventing nuisance overvoltage faults resulting from aggressive

decelerations, overhauling loads, and eccentric loads. However, it can

also cause either of the following two conditions to occur.

1. Fast positive changes in input voltage or imbalanced input voltages

can cause uncommanded positive speed changes;

2. Actual deceleration times can be longer than commanded

deceleration times

However, a “Stall Fault” is generated if the drive remains in this state

for 1 minute. If this condition is unacceptable, the bus regulator must be

disabled (see parameter A117). In addition, installing a properly sized

dynamic brake resistor will provide equal or better performance in most

cases.

ATTENTION: To avoid an electric shock hazard, ensure isolation of

mains supply from line inputs [R, S, T (L1, L2, L3)] and wait three

minutes for capacitors to discharge before removing the external cover.

Once the cover is removed, verify that the voltage on the bus capacitors

has discharged before performing any work on the drive. Measure the

DC bus voltage at the DC– and DC+ terminals on the Power Terminal

Block (refer to page 1-13 for Power Terminal descriptions). The voltage

must be zero

Mounting Considerations

Debris Protection

A plastic top panel is included with the drive. Install the panel to prevent

debris from falling through the vents of the drive housing during

installation. Remove the panel for IP20, NEMA/UL Type Open

applications.

Storage

• Store within an ambient temperature range of -40° to +85°C.

• Store within a relative humidity range of 0% to 95%,

non-condensing.

• Do not expose to a corrosive atmosphere.

AC Supply Source Considerations

General Grounding Requirements

The drive Safety Ground – (PE) must be connected to system

ground. Ground impedance must conform to the requirements of

national and local industrial safety regulations and/or electrical codes.

The integrity of all ground connections should be periodically checked.

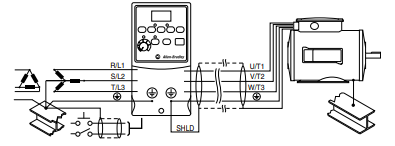

Figure 1.3 Typical Grounding

Ground Fault Monitoring

If a system ground fault monitor (RCD) is to be used, only Type B

(adjustable) devices should be used to avoid nuisance tripping.

Safety Ground – (PE)

This is the safety ground for the drive that is required by code. One of

these points must be connected to adjacent building steel (girder, joist), a

floor ground rod or bus bar. Grounding points must comply with national

and local industrial safety regulations and/or electrical codes.

Motor Ground

The motor ground must be connected to one of the ground terminals on

the drive.

Shield Termination – SHLD

Either of the safety ground terminals located on the power terminal

block provides a grounding point for the motor cable shield. The motor

cable shield connected to one of these terminals (drive end) should also

be connected to the motor frame (motor end). Use a shield terminating or

EMI clamp to connect the shield to the safety ground terminal. The

conduit box option may be used with a cable clamp for a grounding point

for the cable shield.

When shielded cable is used for control and signal wiring, the shield

should be grounded at the source end only, not at the drive end.

RFI Filter Grounding

Using single phase drives with integral filter, or an external filter with

any drive rating, may result in relatively high ground leakage currents.

Therefore, the filter must only be used in installations with grounded

AC supply systems and be permanently installed and solidly

grounded (bonded) to the building power distribution ground. Ensure

that the incoming supply neutral is solidly connected (bonded) to the

same building power distribution ground. Grounding must not rely on

flexible cables and should not include any form of plug or socket that

would permit inadvertent disconnection. Some local codes may require

redundant ground connections. The integrity of all connections should be

periodically checked

Fuses and Circuit Breakers

The PowerFlex 40 does not provide branch short circuit protection. This

product should be installed with either input fuses or an input circuit

breaker. National and local industrial safety regulations and/or electrical

codes may determine additional requirements for these installations.

Fusing

The PowerFlex 40 has been UL tested and approved for use with input

fuses. The ratings in the table that follows are the minimum

recommended values for use with each drive rating. The devices listed in

this table are provided to serve as a guide.

Bulletin 140M (Self-Protected Combination Controller)/UL489

Circuit Breakers

When using Bulletin 140M or UL489 rated circuit breakers, the

guidelines listed below must be followed in order to meet the NEC

requirements for branch circuit protection.

• Bulletin 140M can be used in single and group motor applications.

• Bulletin 140M can be used up stream from the drive without the

need for fuses.

Fuses and Circuit Breakers

!

ATTENTION: To guard against personal injury and/or equipment

damage caused by improper fusing or circuit breaker selection, use only

the recommended line fuses/circuit breakers specified in this section.

Power Wiring

!

ATTENTION: National Codes and standards (NEC, VDE, BSI, etc.)

and local codes outline provisions for safely installing electrical

equipment. Installation must comply with specifications regarding wire

types, conductor sizes, branch circuit protection and disconnect

devices. Failure to do so may result in personal injury and/or equipment

damage.

!

ATTENTION: To avoid a possible shock hazard caused by induced

voltages, unused wires in the conduit must be grounded at both ends.

For the same reason, if a drive sharing a conduit is being serviced or

installed, all drives using this conduit should be disabled. This will help

minimize the possible shock hazard from “cross coupled” power leads.

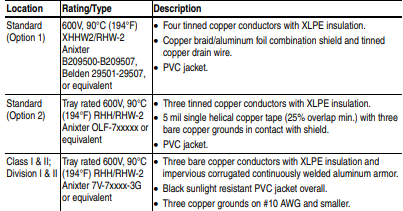

Motor Cable Types Acceptable for 200-600 Volt Installations

A variety of cable types are acceptable for drive installations. For many

installations, unshielded cable is adequate, provided it can be separated

from sensitive circuits. As an approximate guide, allow a spacing of 0.3

meters (1 foot) for every 10 meters (32.8 feet) of length. In all cases,

long parallel runs must be avoided. Do not use cable with an insulation

thickness less than 15 mils (0.4 mm/0.015 in.). Do not route more than

three sets of motor leads in a single conduit to minimize “cross talk”. If

more than three drive/motor connections per conduit are required,

shielded cable must be used.

UL installations in 50°C ambient must use 600V, 75°C or 90°C wire.

UL installations in 40°C ambient should use 600V, 75°C or 90°C wire.

Use copper wire only. Wire gauge requirements and recommendations

are based on 75 degree C. Do not reduce wire gauge when using higher

temperature wire.

Unshielded

THHN, THWN or similar wire is acceptable for drive installation in dry

environments provided adequate free air space and/or conduit fill rates

limits are provided. Do not use THHN or similarly coated wire in wet

areas. Any wire chosen must have a minimum insulation thickness of 15

mils and should not have large variations in insulation concentricity.

Shielded/Armored Cable

Shielded cable contains all of the general benefits of multi-conductor

cable with the added benefit of a copper braided shield that can contain

much of the noise generated by a typical AC Drive. Strong consideration

for shielded cable should be given in installations with sensitive

equipment such as weigh scales, capacitive proximity switches and other

devices that may be affected by electrical noise in the distribution

system. Applications with large numbers of drives in a similar location,

imposed EMC regulations or a high degree of communications /

networking are also good candidates for shielded cable.

Shielded cable may also help reduce shaft voltage and induced bearing

currents for some applications. In addition, the increased impedance of

shielded cable may help extend the distance that the motor can be

located from the drive without the addition of motor protective devices

such as terminator networks. Refer to Reflected Wave in “Wiring and

Grounding Guidelines for PWM AC Drives,” publication

DRIVES-IN001A-EN-P.

Consideration should be given to all of the general specifications

dictated by the environment of the installation, including temperature,

flexibility, moisture characteristics and chemical resistance. In addition,

a braided shield should be included and be specified by the cable

manufacturer as having coverage of at least 75%. An additional foil

shield can greatly improve noise containment.

A good example of recommended cable is Belden® 295xx (xx

determines gauge). This cable has four (4) XLPE insulated conductors

with a 100% coverage foil and an 85% coverage copper braided shield

(with drain wire) surrounded by a PVC jacket.

Other types of shielded cable are available, but the selection of these

types may limit the allowable cable length. Particularly, some of the

newer cables twist 4 conductors of THHN wire and wrap them tightly

with a foil shield. This construction can greatly increase the cable

charging current required and reduce the overall drive performance.

Unless specified in the individual distance tables as tested with the drive,

these cables are not recommended and their performance against the lead

length limits supplied is not known.

Leave a comment

Your email address will not be published. Required fields are marked *