A-BMicroLogix 1000 Programmable ControllersImportant User Information

Because of the variety of uses for the products described in this publication, those responsible

for the application and use of these products must satisfy themselves that all necessary steps

have been taken to assure that each application and use meets all performance and safety

requirements, including any applicable laws, regulations, codes and standards. In no event will

Allen-Bradley be responsible or liable for indirect or consequential damage resulting from the

use or application of these products.

Any illustrations, charts, sample programs, and layout examples shown in this publication are

intended solely for purposes of example. Since there are many variables and requirements

associated with any particular installation, Allen-Bradley does not assume responsibility or

liability (to include intellectual property liability) for actual use based upon the examples

shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the Application, Installation and Maintenance

of Solid-State Control (available from your local Allen-Bradley office), describes some important

differences between solid-state equipment and electromechanical devices that should be taken

into consideration when applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in whole or part, without

written permission of Rockwell Automation, is prohibited.

Throughout this publication, notes may be used to make you aware of safety considerations.

The following annotations and their accompanying statements help you to identify a potential

hazard, avoid a potential hazard, and recognize the consequences of a potential hazard:

WARNING

!

Identifies information about practices or circumstances that can cause

an explosion in a hazardous environment, which may lead to personal

injury or death, property damage, or economic loss.

ATTENTION

!

Identifies information about practices or circumstances that can lead

to personal injury or death, property damage, or economic loss.

IMPORTANT Identifies information that is critical for successful application and

understanding of the product.

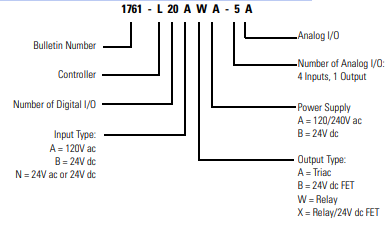

Overview Install your controller using these installation instructions. The only tools you require are a Flat head or Phillips head screwdriver and drill. Catalog Number Detail The catalog number for the controller is composed of the following:

For More Information

Related Publications

If you would like a manual, you can:

• download a free electronic version from the internet:

http://literature.rockwellautomation.com

• purchase a printed manual by contacting your local Allen-Bradley distributor or

Rockwell Automation representative

For Refer to this Document Pub. No.

A description on how to use your MicroLogix 1000

programmable controllers. This manual also contains

status file data and instruction set information.

MicroLogix 1000 Programmable

Controllers User Manual

1761-6.3

A procedural manual for technical personnel who use the

Allen-Bradley Hand-Held Programmer (HHP) to monitor

and develop control logic programs for the MicroLogix

1000 controller.

MicroLogix 1000 with Hand-Held

Programmer (HHP) User Manual

1761-6.2

More information on proper wiring and grounding

techniques.

Industrial Automation Wiring and

Grounding Guidelines

1770-4.1

The procedures necessary to install and connect the AIC+

and DNI.

Advanced Interface Converter

(AIC+) and DeviceNet Interface

(DNI) Installation Instructions

1761-5.11

A more detailed description on how to install and use your

AIC+ Advanced Interface Converter.

AIC+ Advanced Interface Converter

User Manual

1761-6.4

A more detailed description on how to install and use your

DeviceNet Interface.

DeviceNet Interface User Manual 1761-6.5

A more detailed description on how to install and use your

Ethernet Interface.

Ethernet Interface User Manual 1761-UM006

Safety Considerations

This equipment is suitable for use in Class I, Division 2, Groups A, B, C, D or non-hazardous

locations only (when product or packing is marked).

Use only the following communication cables in Class I, Division 2, Hazardous Locations.

WARNING

!

Explosion Hazard:

• Substitution of components may impair suitability for Class I,

Division 2.

• Do not replace components or disconnect equipment unless

power has been switched off and the area is known to be

non-hazardous.

• Do not connect or disconnect connectors while circuit is live

unless area is known to be non-hazardous.

• This product must be installed in an enclosure. All cables

connected to the product must remain in the enclosure or be

protected by conduit or other means.

• The interior of the enclosure must be accessible only by the use

of a tool.

• For applicable equipment (for example, relay modules), exposure

to some chemicals may degrade the sealing properties of the

materials used in these devices:

– Relays, epoxy

It is recommended that you periodically inspect these devices for

any degradation of properties and replace the module if

degradation is found.

Sécurité

Cet équipement est conçu pour être utilisé dans des environnements de Classe 1, Division 2,

Groupes A, B, C, D ou non dangereux (si indiqué sur le produit ou l’emballage).

N’utiliser que les câbles de communication suivants dans des environnements dangereux de

Classe 1, Division 2.

AVERTISSEMENT

!

Danger d’explosion :

• La substitution de composants peut rendre cet équipement

impropre à une utilisation en environnement de Classe 1,

Division 2.

• Ne pas remplacer de composants ou déconnecter l’équipement

sans s’être assuré que l’alimentation est coupée et que

l’environnement est classé non dangereux.

• Ne pas connecter ou déconnecter les connecteurs lorsque le

circuit est alimenté, à moins que l’environnement ne soit classé

non dangereux.

• Ce produit doit être installé dans un boîtier. Tous les câbles qui lui

sont connectés doivent rester dans le boîtier ou être protégés.

Mounting Your Controller Horizontally

The controller should be mounted horizontally within an enclosure using either the DIN rail

or mounting screw option. Use the mounting template from the front of this document to

help you space and mount the controller properly.

Using a DIN Rail

To install your controller on the DIN rail:

1. Mount your DIN rail. (Make sure that the

placement of the controller on the DIN rail

meets the recommended spacing

requirements. Refer to the mounting template

from the back of this document.)

2. Hook the top slot over the DIN rail.

3. While pressing the controller against the rail,

snap the controller into position.

4. Leave the protective wrap attached until you

are finished wiring the controller.

Using Mounting Screws

To install your controller using mounting

screws:

1. Remove the mounting template from the

back of this document.

2. Secure the template to the mounting

surface. (Make sure your controller is

spaced properly.)

3. Drill holes through the template.

4. Remove the mounting template.

5. Mount the controller.

6. Leave the protective wrap attached until you are finished wiring the controller.

Mounting Your Controller Vertically

Your controller can also be mounted vertically within an enclosure using mounting screws or

a DIN rail. To insure the stability of your controller, we recommend using mounting screws.

For additional information, refer to the previous section.

To insure the controller’s reliability, the following environmental specifications must not be

exceeded.

Grounding Your Controller

In solid-state control systems, grounding helps limit the effects of noise due to

electromagnetic interference (EMI). Run the ground connection from the ground screw of

the controller (third screw from left on output terminal rung) to the ground bus. Use the

heaviest wire gauge listed for wiring your controller.

You must also provide an acceptable grounding path for each device in your application. For

more information on proper grounding guidelines, see the Industrial Automation Wiring and

Grounding Guidelines, (publication 1770-4.1).

ATTENTION

!

All devices connected to the user 24V power supply or to the RS-232

channel must be referenced to chassis ground or floating. Failure to

follow this procedure may result in property damage or personal

injury.

Chassis ground, user 24V ground, and the RS-232 ground are

internally connected. You must connect the chassis ground terminal

screw to chassis ground prior to connecting any devices.

On the 1761-L10BWB, -L10BXB, -L16BWB, -L16BBB, -L16NWB,

-L20BWB-5A, -L32BBB, and -L32BWB controllers, the ground

associated with the user supplied 24V DC input power and chassis

ground are internally connected.

Surge Suppression

Inductive load devices such as motor starters and solenoids require the use of some type of

surge suppression to protect the controller output contacts. Switching inductive loads

without surge suppression can significantly reduce the life expectancy of relay contacts. By

adding a suppression device directly across the coil of inductive devices, you prolong the life

of the output circuits. You also reduce the effects of radiated voltage transients and prevent

electrical noise from radiating into system wiring and facility.

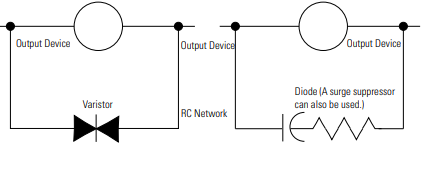

The following diagram shows an output with a suppression device. We recommend that you

locate the suppression device as close as possible to the load device.

If you connect a micro controller FET output to an inductive load, we recommend that you

use an 1N4004 diode for surge suppression, as shown in the illustration on page 17.

Suitable surge suppression methods for inductive load devices include a varistor, an RC

network, or, for dc loads, a diode. These components must be appropriately rated to suppress

the switching transient characteristic of the particular inductive device. See the table on

page 18 for recommended suppressors.

As the following diagram illustrates, these surge suppression circuits connect directly across

the load device. This reduces arcing and damage of the output contacts. (High transients can

cause arcing that occurs when switching off an inductive device.)

If you connect a micro controller triac output to control an inductive load, we recommend

that you use varistors to suppress noise. Choose a varistor that is appropriate for the

application. The suppressors we recommend for triac outputs when switching 120V ac

inductive loads are a Harris MOV, part number V175 LA10A, or an Allen-Bradley MOV,

catalog number 599-K04 or 599-KA04. Consult the varistor manufacturer’s data sheet when

selecting a varistor for your application.

For inductive dc load devices, a diode is suitable. A 1N4004 diode is acceptable for most

applications. A surge suppressor can also be used. See the table on page 18 for

recommended suppressors.

Surge Suppression for Inductive ac Load Device

Minimizing Electrical Noise on Analog Controllers

Inputs on analog controllers employ digital high-frequency filters that significantly reduce the

effects of electrical noise on input signals. However, because of the variety of applications and

environments where analog controllers are installed and operated, it is impossible to ensure

that all environmental noise will be removed by the input filters.

Several specific steps can be taken to help reduce the effects of environmental noise on

analog signals:

• install the MicroLogix 1000 system in a properly rated (i.e., NEMA) enclosure. Make

sure that the MicroLogix 1000 system is properly grounded.

• use Belden cable #8761 for wiring the analog channels, making sure that the drain

wire and foil shield are properly earth grounded.

• route the Belden cable separate from any ac wiring. Additional noise immunity can be

obtained by routing the cables in grounded conduit.

Grounding Your Analog Cable

Use shielded communication

cable (Belden #8761). The Belden

cable has two signal wires (black

and clear), one drain wire, and a

foil shield. The drain wire and foil

shield must be grounded at one

end of the cable. Do not ground

the drain wire and foil shield at

both ends of the cable.

Specifications

Environmental Specifications (all MicroLogix controllers)

Description Specification

Operating Temperature 0°C to +55°C (+32°F to +131°F) for horizontal mounting

Important User Information

Because of the variety of uses for the products described in this publication, those responsible

for the application and use of these products must satisfy themselves that all necessary steps

have been taken to assure that each application and use meets all performance and safety

requirements, including any applicable laws, regulations, codes and standards. In no event will

Allen-Bradley be responsible or liable for indirect or consequential damage resulting from the

use or application of these products.

Any illustrations, charts, sample programs, and layout examples shown in this publication are

intended solely for purposes of example. Since there are many variables and requirements

associated with any particular installation, Allen-Bradley does not assume responsibility or

liability (to include intellectual property liability) for actual use based upon the examples

shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the Application, Installation and Maintenance

of Solid-State Control (available from your local Allen-Bradley office), describes some important

differences between solid-state equipment and electromechanical devices that should be taken

into consideration when applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in whole or part, without

written permission of Rockwell Automation, is prohibited.

Throughout this publication, notes may be used to make you aware of safety considerations.

The following annotations and their accompanying statements help you to identify a potential

hazard, avoid a potential hazard, and recognize the consequences of a potential hazard:

WARNING

!

Identifies information about practices or circumstances that can cause

an explosion in a hazardous environment, which may lead to personal

injury or death, property damage, or economic loss.

ATTENTION

!

Identifies information about practices or circumstances that can lead

to personal injury or death, property damage, or economic loss.

IMPORTANT Identifies information that is critical for successful application and

understanding of the product.

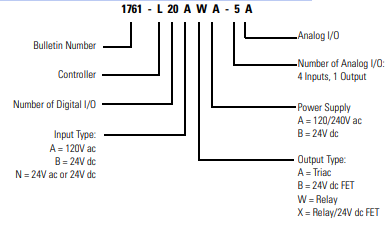

Overview Install your controller using these installation instructions. The only tools you require are a Flat head or Phillips head screwdriver and drill. Catalog Number Detail The catalog number for the controller is composed of the following:

For More Information

Related Publications

If you would like a manual, you can:

• download a free electronic version from the internet:

http://literature.rockwellautomation.com

• purchase a printed manual by contacting your local Allen-Bradley distributor or

Rockwell Automation representative

For Refer to this Document Pub. No.

A description on how to use your MicroLogix 1000

programmable controllers. This manual also contains

status file data and instruction set information.

MicroLogix 1000 Programmable

Controllers User Manual

1761-6.3

A procedural manual for technical personnel who use the

Allen-Bradley Hand-Held Programmer (HHP) to monitor

and develop control logic programs for the MicroLogix

1000 controller.

MicroLogix 1000 with Hand-Held

Programmer (HHP) User Manual

1761-6.2

More information on proper wiring and grounding

techniques.

Industrial Automation Wiring and

Grounding Guidelines

1770-4.1

The procedures necessary to install and connect the AIC+

and DNI.

Advanced Interface Converter

(AIC+) and DeviceNet Interface

(DNI) Installation Instructions

1761-5.11

A more detailed description on how to install and use your

AIC+ Advanced Interface Converter.

AIC+ Advanced Interface Converter

User Manual

1761-6.4

A more detailed description on how to install and use your

DeviceNet Interface.

DeviceNet Interface User Manual 1761-6.5

A more detailed description on how to install and use your

Ethernet Interface.

Ethernet Interface User Manual 1761-UM006

Safety Considerations

This equipment is suitable for use in Class I, Division 2, Groups A, B, C, D or non-hazardous

locations only (when product or packing is marked).

Use only the following communication cables in Class I, Division 2, Hazardous Locations.

WARNING

!

Explosion Hazard:

• Substitution of components may impair suitability for Class I,

Division 2.

• Do not replace components or disconnect equipment unless

power has been switched off and the area is known to be

non-hazardous.

• Do not connect or disconnect connectors while circuit is live

unless area is known to be non-hazardous.

• This product must be installed in an enclosure. All cables

connected to the product must remain in the enclosure or be

protected by conduit or other means.

• The interior of the enclosure must be accessible only by the use

of a tool.

• For applicable equipment (for example, relay modules), exposure

to some chemicals may degrade the sealing properties of the

materials used in these devices:

– Relays, epoxy

It is recommended that you periodically inspect these devices for

any degradation of properties and replace the module if

degradation is found.

Sécurité

Cet équipement est conçu pour être utilisé dans des environnements de Classe 1, Division 2,

Groupes A, B, C, D ou non dangereux (si indiqué sur le produit ou l’emballage).

N’utiliser que les câbles de communication suivants dans des environnements dangereux de

Classe 1, Division 2.

AVERTISSEMENT

!

Danger d’explosion :

• La substitution de composants peut rendre cet équipement

impropre à une utilisation en environnement de Classe 1,

Division 2.

• Ne pas remplacer de composants ou déconnecter l’équipement

sans s’être assuré que l’alimentation est coupée et que

l’environnement est classé non dangereux.

• Ne pas connecter ou déconnecter les connecteurs lorsque le

circuit est alimenté, à moins que l’environnement ne soit classé

non dangereux.

• Ce produit doit être installé dans un boîtier. Tous les câbles qui lui

sont connectés doivent rester dans le boîtier ou être protégés.

Mounting Your Controller Horizontally

The controller should be mounted horizontally within an enclosure using either the DIN rail

or mounting screw option. Use the mounting template from the front of this document to

help you space and mount the controller properly.

Using a DIN Rail

To install your controller on the DIN rail:

1. Mount your DIN rail. (Make sure that the

placement of the controller on the DIN rail

meets the recommended spacing

requirements. Refer to the mounting template

from the back of this document.)

2. Hook the top slot over the DIN rail.

3. While pressing the controller against the rail,

snap the controller into position.

4. Leave the protective wrap attached until you

are finished wiring the controller.

Using Mounting Screws

To install your controller using mounting

screws:

1. Remove the mounting template from the

back of this document.

2. Secure the template to the mounting

surface. (Make sure your controller is

spaced properly.)

3. Drill holes through the template.

4. Remove the mounting template.

5. Mount the controller.

6. Leave the protective wrap attached until you are finished wiring the controller.

Mounting Your Controller Vertically

Your controller can also be mounted vertically within an enclosure using mounting screws or

a DIN rail. To insure the stability of your controller, we recommend using mounting screws.

For additional information, refer to the previous section.

To insure the controller’s reliability, the following environmental specifications must not be

exceeded.

Grounding Your Controller

In solid-state control systems, grounding helps limit the effects of noise due to

electromagnetic interference (EMI). Run the ground connection from the ground screw of

the controller (third screw from left on output terminal rung) to the ground bus. Use the

heaviest wire gauge listed for wiring your controller.

You must also provide an acceptable grounding path for each device in your application. For

more information on proper grounding guidelines, see the Industrial Automation Wiring and

Grounding Guidelines, (publication 1770-4.1).

ATTENTION

!

All devices connected to the user 24V power supply or to the RS-232

channel must be referenced to chassis ground or floating. Failure to

follow this procedure may result in property damage or personal

injury.

Chassis ground, user 24V ground, and the RS-232 ground are

internally connected. You must connect the chassis ground terminal

screw to chassis ground prior to connecting any devices.

On the 1761-L10BWB, -L10BXB, -L16BWB, -L16BBB, -L16NWB,

-L20BWB-5A, -L32BBB, and -L32BWB controllers, the ground

associated with the user supplied 24V DC input power and chassis

ground are internally connected.

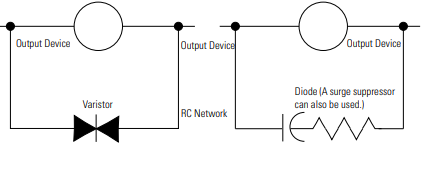

Surge Suppression

Inductive load devices such as motor starters and solenoids require the use of some type of

surge suppression to protect the controller output contacts. Switching inductive loads

without surge suppression can significantly reduce the life expectancy of relay contacts. By

adding a suppression device directly across the coil of inductive devices, you prolong the life

of the output circuits. You also reduce the effects of radiated voltage transients and prevent

electrical noise from radiating into system wiring and facility.

The following diagram shows an output with a suppression device. We recommend that you

locate the suppression device as close as possible to the load device.

If you connect a micro controller FET output to an inductive load, we recommend that you

use an 1N4004 diode for surge suppression, as shown in the illustration on page 17.

Suitable surge suppression methods for inductive load devices include a varistor, an RC

network, or, for dc loads, a diode. These components must be appropriately rated to suppress

the switching transient characteristic of the particular inductive device. See the table on

page 18 for recommended suppressors.

As the following diagram illustrates, these surge suppression circuits connect directly across

the load device. This reduces arcing and damage of the output contacts. (High transients can

cause arcing that occurs when switching off an inductive device.)

If you connect a micro controller triac output to control an inductive load, we recommend

that you use varistors to suppress noise. Choose a varistor that is appropriate for the

application. The suppressors we recommend for triac outputs when switching 120V ac

inductive loads are a Harris MOV, part number V175 LA10A, or an Allen-Bradley MOV,

catalog number 599-K04 or 599-KA04. Consult the varistor manufacturer’s data sheet when

selecting a varistor for your application.

For inductive dc load devices, a diode is suitable. A 1N4004 diode is acceptable for most

applications. A surge suppressor can also be used. See the table on page 18 for

recommended suppressors.

Surge Suppression for Inductive ac Load Device

Minimizing Electrical Noise on Analog Controllers

Inputs on analog controllers employ digital high-frequency filters that significantly reduce the

effects of electrical noise on input signals. However, because of the variety of applications and

environments where analog controllers are installed and operated, it is impossible to ensure

that all environmental noise will be removed by the input filters.

Several specific steps can be taken to help reduce the effects of environmental noise on

analog signals:

• install the MicroLogix 1000 system in a properly rated (i.e., NEMA) enclosure. Make

sure that the MicroLogix 1000 system is properly grounded.

• use Belden cable #8761 for wiring the analog channels, making sure that the drain

wire and foil shield are properly earth grounded.

• route the Belden cable separate from any ac wiring. Additional noise immunity can be

obtained by routing the cables in grounded conduit.

Grounding Your Analog Cable

Use shielded communication

cable (Belden #8761). The Belden

cable has two signal wires (black

and clear), one drain wire, and a

foil shield. The drain wire and foil

shield must be grounded at one

end of the cable. Do not ground

the drain wire and foil shield at

both ends of the cable.

Specifications

Environmental Specifications (all MicroLogix controllers)

Description Specification

Operating Temperature 0°C to +55°C (+32°F to +131°F) for horizontal mounting

0°C to +40°C (+32°F to +104°F) for vertical mounting(1

Leave a comment

Your email address will not be published. Required fields are marked *