KEY FEATURES AND BENEFITS

• From the vibro-meter® product line

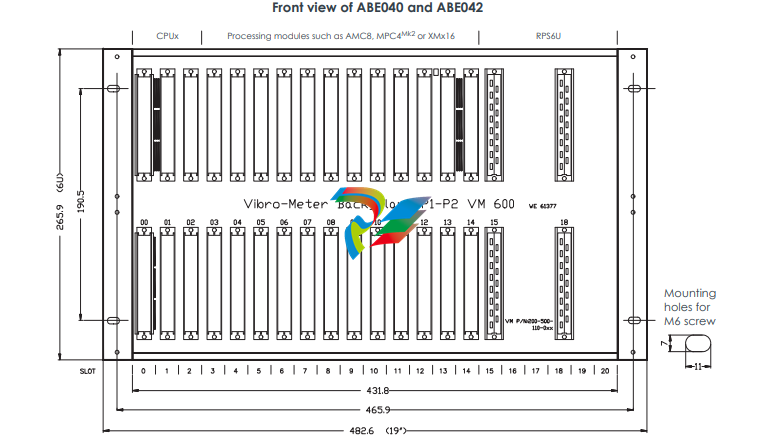

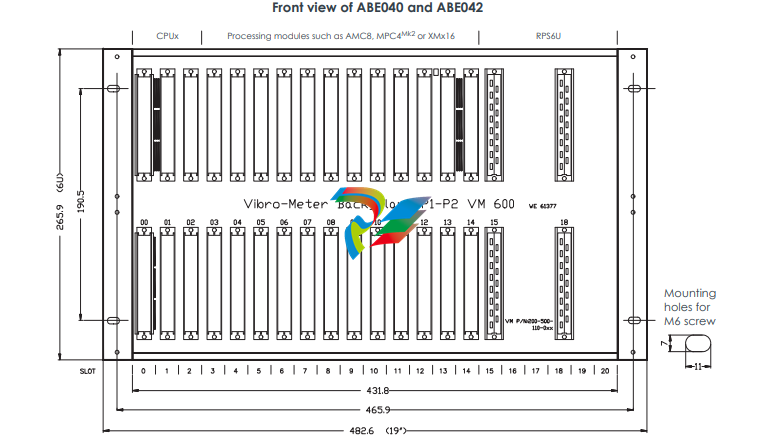

• 19″ system racks with a standard height of 6U

• Robust aluminium construction

• Modular concept allows specific cards to be

added for machinery protection and/or

condition monitoring

• Cabinet or panel mounting

• Backplane supporting the VME bus, the

VM600Mk2/VM600 system’s Tacho, Raw and

Open collector (OC) buses, and power supply

distribution

• Uses the VM600Mk2/VM600 RPS6U rack power

supply: AC and/or DC input versions

• Power supply check relay

APPLICATIONS

• VM600Mk2/VM600 machinery protection and/

or condition monitoring systems

DESCRIPTION

The VM600Mk2/VM600 ABE040 and ABE042 system

racks are used to house hardware for the

VM600Mk2/VM600 series of machinery protection

and/or condition monitoring systems, from

Meggitt’s vibro-meter® product line.

Two types of VM600Mk2/VM600 ABE04x system

rack are available: the ABE040 and the ABE042.

These are very similar, differing only in the position

of the mounting brackets. Both racks have a

standard height of 6U and provide mounting

space (rack slots) for up to 12 single-width

VM600Mk2/VM600 modules (card pairs), or a

combination of single-width and multiple-width

modules (cards). These racks are particularly

suitable for industrial environments, where

equipment must be permanently installed in 19″

cabinets or panels.

DESCRIPTION (continued)

The different versions of ABE04x system rack

enable different mounting options to support

various markets and applications.

The VM600 system rack has an integrated VME

backplane which provides the electrical

interconnections between the installed

VM600Mk2/VM600 modules (cards): power supply,

signal processing, input /output, relay and

CPUx “rack controller”. It also includes a power

supply check relay, available at the rear of the

rack, which is used to indicate that the installed

RPS6U rack power supplies are operating

normally.

Either one or two RPS6U rack power supplies can

be installed in a VM600Mk2/VM600 ABE04x system

rack. A rack with one RPS6U power supply (330 W

version) supports the power requirements for a full

rack of modules (cards) in applications with

operating temperatures up to 50°C (122°F).

Alternatively, a rack can have two RPS6U power

supplies installed in order to either support rack

power supply redundancy or in order to supply

power to the modules (cards) non-redundantly

over a wider range of environmental conditions

(see Power supply on page 4).

VM600Mk2/VM600 processing modules (cards) are

installed in the front of the rack and the

associated input/output modules (cards) are

installed in the rear. The input/output modules

(cards) provide connectors for the connection of

sensors/measurement chains and for the sharing

of various signals with external systems such as a

DCS or PLC.

In general, VM600Mk2/VM600 ABE04x system racks

are configured in the factory before delivery so

they are supplied ready-to-use. Optionally, each

module (card) can be reconfigured to meet the

needs of a particular machinery monitoring

application using the appropriate software

package from Meggitt vibro-meter®:

VM600 MPSx or VibroSight®.

For further information, contact your local

Meggitt representative.

General

Housing : Extruded aluminium frame and solid aluminium structural parts.

Top and bottom plastic guide strips for VM600Mk2/VM600 modules

(cards).

Colour : Aluminium

Power supply : The VM600Mk2/VM600 RPS6U rack power supply is used to provide

the VM600Mk2/VM600 rack itself and all installed modules (cards)

with +5 VDC and ±12 VDC.

See also Power supply on page 4.

Power supply inputs : Power supply inputs (associated rear panels) typically have an AC

and/or DC connector (with RFI filters), on/off switches and fuses.

Refer to the VM600Mk2/VM600 RPS6U rack power supplies

data sheet for information on power supply inputs, associated rear

panels and mains power supply leads (power cords).

Backplane : Proprietary VM600Mk2/VM600 rack buses (Tacho bus, Raw bus and

Open collector (OC) bus) for data/signal sharing between modules

(cards).

VME bus for communication between CPUx modules (cards) and

processing modules (cards).

General

Housing : Extruded aluminium frame and solid aluminium structural parts.

Top and bottom plastic guide strips for VM600Mk2/VM600 modules

(cards).

Colour : Aluminium

Power supply : The VM600Mk2/VM600 RPS6U rack power supply is used to provide

the VM600Mk2/VM600 rack itself and all installed modules (cards)

with +5 VDC and ±12 VDC.

See also Power supply on page 4.

Power supply inputs : Power supply inputs (associated rear panels) typically have an AC

and/or DC connector (with RFI filters), on/off switches and fuses.

Refer to the VM600Mk2/VM600 RPS6U rack power supplies

data sheet for information on power supply inputs, associated rear

panels and mains power supply leads (power cords).

Backplane : Proprietary VM600Mk2/VM600 rack buses (Tacho bus, Raw bus and

Open collector (OC) bus) for data/signal sharing between modules

(cards).

VME bus for communication between CPUx modules (cards) and

processing modules (cards).

Rack slots

(module (card) positions)

: Front of rack:

• 12 × slots – module (card) positions 03 to 14 – for processing

modules (cards) such as MPC4Mk2, XMx16, MPC4 and/or AMC8.

• 2 × slots – module (card) positions 00 to 01 – for rack controller

and communications interface modules (cards) such as CPUMMk2

or CPUx.

• 1 × slot – module (card) position 02 – reserved for applicationspecific modules (cards).

Rear of rack:

• Up to 19 × slots – module (card) positions 00 to 18 – for associated

input/output modules (cards) such as IOC4Mk2, XIO16T, IOC4T and/

or IOC8T, IOCNMk2 or IOCx, and relay modules (cards) such as

RLC16Mk2, RLC16 and/or IRC4.

• Up to 4 × slots – module (card) positions 17 to 20 – for associated

rear panels for inputs to the VM600Mk2/VM600 RPS6U rack power

supply or supplies.

See also Mechanical drawings – front and rear views on page 6.

Notes

In general, associated input/output modules (cards) are required

while relay modules (cards) are optional.

For safety reasons, any VM600Mk2/VM600 rack slot not populated

by a module (card) must be covered by a blank panel(s).

Rack slot number coding : For modules (cards) installed in the rear of an ABE04x rack, an

electronic keying mechanism known as slot number coding is used

to help ensure that the module (card) is installed in the correct slot,

as defined by the configuration (that is, by the VibroSight® or

VM600 MPSx software).

For ABE04x racks, the rack’s slot numbers are fixed (hard-wired) and

slot number coding requires that a module’s slot number is set to

match the rack slot (module (card) position) where it is installed.

Slot number coding range : 3 to 14

Slot number coding defaults : Fixed (hard-wired) as follows:

• Slot 03 = 3 (0011 binary)

• Slot 04 = 4 (0100 binary)

…

• Slot 13 = 13 (1101 binary)

• Slot 14 = 14 (1110 binary).

Galvanic separation : Galvanic separation units (GSIxxx) are available for accelerometer

and proximity systems mounted in explosive atmospheres. These

units cannot be supplied by the rack and require an external power

supply. They must be mounted outside the rack in a remote housing

or in a cabinet.

Power supply

VM600Mk2/VM600 RPS6U rack power

supplies

: A VM600Mk2/VM600 ABE04x system rack can have either one or

two RPS6U rack power supplies installed, as follows:

• 1 × RPS6U power supply (330 W) supports the power requirements

for a full rack of modules (cards) in applications with operating

temperatures up to 50°C (122°F).

• 2 × RPS6U power supplies (330 W) – operating redundantly –

supports the power requirements for a full rack of modules (cards)

in applications with operating temperatures up to 50°C (122°F).

With this rack power supply redundancy, if one RPS6U fails, the

other will provide 100% of the rack’s power requirements so that the

rack will continue to operate.

Note: This is known as a redundant RPS6U rack power supply

configuration.

• 2 × RPS6U power supplies (330 W) – operating non-redundantly –

supports the power requirements for a full rack of modules (cards)

in applications with operating temperatures above 50°C (122°F),

where RPS6U output power derating is required.

Note: Even though two RPS6U rack power supplies are installed in

the rack, this is not a redundant RPS6U rack power supply

configuration.

Refer to the VM600Mk2/VM600 RPS6U rack power supplies

data sheet and a VM600Mk2/VM600 machinery protection system

(MPS) hardware manual for further information.

Power supply check relay

Nominal switching capacity

(resistive load)

: 4 A / 250 VAC, 3 A / 30 VDC

Maximum switching power

(resistive load)

: 1000 VA, 90 W

Maximum switching voltage : ±30 VRMS / ±42.4 VAC(PEAK) or 60 VDC

Maximum switching current : 4 AAC, 3 ADC

Environmental

According to IEC 60068-2 recommendations

Temperature

• Operating : 0 to 70°C (32 to 158°F)

• Storage : −40 to 85°C (−40 to 185°F)

Humidity : 0 to 90%, non-condensing

Vibration : 10 to 55 Hz, 0.35 mm peak, 6 hours in each direction

Shock : 15 g peak, 11 ms, half-sine pulse

Indoor use : Limited to indoor use only

Approvals

Conformity : European Union (EU) declaration of conformity (CE marking).

CCSAUS certificate of compliance.

EAC marking, Eurasian Customs Union (EACU) certificate/

declaration of conformity.

Electromagnetic compatibility : IEC/EN 61000-6-2 and IEC/EN 61000-6-4.

TR CU 020/2011.

Electrical safety : IEC/EN 61010-1.

TR CU 004/2011.

Vibration : IEC 60255-21-1 (Class 2)

Environmental management : RoHS compliant

Russian federal agency for technical

regulation and metrology (Rosstandart)

: Pattern approval certificate OC.C.28.004.A N° 60224

Physical

Dimensions : See Mechanical drawings starting on page 4

Weight : 6.5 kg (14.3 lb) approx.

without RPS6U power supplies and modules (cards)

S

Type Designation Ordering number (PNR)

ABE040 Different versions of the VM600Mk2 ABE040 system rack:

– Standard version 204-040-100-016

ABE040 Different versions of the VM600Mk2/VM600 ABE040 system rack:

– Standard version 204-040-100-015

– Varnished version, with a conformal coating for additional

environmental protection 204-040-100-015L

– Separate circuits version, in accordance with the IEC 60255-5 standard 204-040-100-115

– CCSAUS version, in accordance with the IEC 61010-1 standard 204-040-100-214

ABE042 Different versions of the VM600Mk2/VM600 ABE042 system rack:

– Version with mounting brackets positioned at the rear of the rack 204-042-100-01h

– Varnished version, with a conformal coating for additional

environmental protection 204-042-100-01hL

Different blank panel kits for the front of a VM600Mk2 ABE04x system rack:

– 1 × slot wide / 4 HP (TE) 200-505-011-012

– 3 × slots wide / 12 HP (TE) 200-505-018-012

Different blank panel kits for the rear of a VM600Mk2 ABE04x system rack:

– 1 × slot wide / 4 HP (TE) 200-505-011-012

Different blank panel kits for the front of a VM600 ABE04x system rack:

– 1 × slot wide / 4 HP (TE) 200-505-015-011

– 2 × slots wide / 8 HP (TE) 200-505-016-011

– 3 × slots wide / 12 HP (TE) 200-505-018-011

– 4 × slots wide / 16 HP (TE) 200-505-017-011

Different blank panel kits for the rear of a VM600 ABE04x system rack:

– 1 × slot wide / 4 HP (TE) 200-505-011-011

– 2 × slots wide / 8 HP (TE) 200-505-012-011

– 4 × slots wide / 16 HP (TE) 200-505-013-011

Notes

In an ordering number (PNR), “h” represents the hardware version.

The standard version of the VM600Mk2 ABE040 system rack (PNR 204-040-100-016) and the standard version of the VM600Mk2/VM600

ABE040 system rack (PNR 204-040-100-015 or earlier) are the same, except for the specific artwork/branding/finish. More specifically,

the mounting brackets on the side of the ABE040 system rack are bare aluminium for the VM600Mk2 versions and painted for the

VM600Mk2/VM600 versions. See also Ordering guidelines on page 9.

For safety reasons, any VM600Mk2/VM600 ABE04x system rack slot not populated by a module (card) must be covered by a blank

panel(s).

(The width of a 19″ rack is typically measured in horizontal pitch (HP) units of 5.08 mm (0.2″), also known as standard width (TE) units.

For the VM600Mk2/VM600 ABE04x System racks, a 1 × slot wide blank panel suitable for covering one module (card) position

corresponds to 4 HP (TE), a 2 × slots wide blank panel corresponds to 8 HP (TE), a 3 × slots wide blank panel corresponds to 12 HP (TE)

and so on.)

When only one RPS6U power supply is installed in a VM600Mk2/VM600 ABE04x system rack (PS1 in rack slots 18 to 20), the unused

power supply position (PS2 in rack slots 15 to 17) should be populated with a blank panel(s).

ORDERING GUIDELINES

The ordering numbers (PNRs) given in Ordering information on page 8 of this data sheet should be used when

ordering a VM600Mk2/VM600 ABE04x system rack and/or blank panels as individual system components for use

as a replacement or spare part.

However, when ordering these components with other system components as part of a complete

VM600Mk2/VM600 machinery monitoring system, then a VM600SYS-based ordering number should be used.

Contact your local Meggitt representative for further information.

RELATED PRODUCTS

VM600Mk2 (second generation)

ABE056 VM600Mk2/VM600 slimline rack : Refer to corresponding data sheet

ASPS VM600Mk2/VM600 auxiliary sensor power

supply

: Refer to corresponding data sheet

CPUMMk2 + IOCNMk2 VM600Mk2 rack controller and

communications interface module

: Refer to corresponding data sheet

MPC4Mk2 + IOC4Mk2 VM600Mk2 machinery protection and

condition monitoring module

: Refer to corresponding data sheet

RLC16Mk2 VM600Mk2 relay module : Refer to corresponding data sheet

RPS6U VM600Mk2/VM600 rack power supplies : Refer to corresponding data sheet

XMx16 + XIO16T VM600Mk2/VM600 condition monitoring

modules

: Refer to corresponding data sheet

VibroSight VibroSight® machinery monitoring system

software

: Refer to corresponding data sheet

VM600 (first generation)

ABE056 VM600Mk2/VM600 slimline rack : Refer to corresponding data sheet

AMC8 and IOC8T VM600 analog monitoring card pair : Refer to corresponding data sheet

ASPS VM600Mk2/VM600 auxiliary sensor power

supply

: Refer to corresponding data sheet

CPUM and IOCN VM600 modular CPU card and

input/output card.

Note: With a front-panel display and support

for Modbus RTU/TCP or PROFINET.

: Refer to corresponding data sheet

CPUR and IOCR VM600 rack controller and communications

interface card pair.

Note: With rack controller redundancy and

support for Modbus RTU/TCP.

: Refer to corresponding data sheet

CPUR2 and IOCR2 VM600 rack controller and communications

interface card pair.

Note: With mathematical processing of

fieldbus data and support for Modbus TCP

and PROFIBUS.

: Refer to corresponding data sheet

IRC4 VM600 intelligent relay card : Refer to corresponding data sheet

MPC4 and IOC4T VM600 machinery protection card pair : Refer to corresponding data sheets

RLC16 VM600 relay card : Refer to corresponding data sheet

RPS6U VM600Mk2/VM600 rack power supplies : Refer to corresponding data sheet

XMx16 + XIO16T VM600Mk2/VM600 condition monitoring

modules

: Refer to corresponding data sheet

Meggitt (Meggitt PLC) is a leading international engineering company, headquartered in England, that designs and delivers high-performance

components and subsystems for aerospace, defence and selected energy markets. Meggitt comprises four customer-aligned divisions:

Airframe Systems, Engine Systems, Energy & Equipment and Services & Support.

The Energy & Equipment division includes the Energy Sensing and Controls product group that specialises in sensing and monitoring solutions for a

broad range of energy infrastructure, and control valves for industrial gas turbines, primarily for the Power Generation, Oil & Gas and Services markets.

Energy & Equipment is headquartered in Switzerland (Meggitt SA) and incorporates the vibro-meter® product line, which has over 65 years of sensor

and systems expertise and is trusted by original equipment manufacturers (OEMs) globally.

All information in this document, such as descriptions, specifications, drawings, recommendations and other statements, is believed to be

reliable and is stated in good faith as being approximately correct, but is not binding on Meggitt (Meggitt SA) unless expressly agreed in

writing. Before acquiring and/or using this product, you must evaluate it and determine if it is suitable for your intended application. You

should also check our website at www.meggittsensing.com/energy for any updates to data sheets, certificates, product drawings, user

manuals, service bulletins and/or other instructions affecting the product.

Unless otherwise expressly agreed in writing with Meggitt SA, you assume all risks and liability associated with use of the product. Any

recommendations and advice given without charge, whilst given in good faith, are not binding on Meggitt SA. Meggitt (Meggitt SA) takes

no responsibility for any statements related to the product which are not contained in a current Meggitt SA publication, nor for any

statements contained in extracts, summaries, translations or any other documents not authored and produced by Meggitt SA.

The certifications and warranties applicable to the products supplied by Meggitt SA are valid only for new products purchased directly from

Meggitt SA or from an authorised distributor of Meggitt SA.

In this publication, a dot (.) is used as the decimal separator and thousands are separated by thin spaces. Example: 12345.67890.

Copyright© 2022 Meggitt SA. All rights reserved. The information contained in this document is subject to change without prior noticeKEY FEATURES AND BENEFITS

• From the vibro-meter® product line

• 19″ system racks with a standard height of 6U

• Robust aluminium construction

• Modular concept allows specific cards to be

added for machinery protection and/or

condition monitoring

• Cabinet or panel mounting

• Backplane supporting the VME bus, the

VM600Mk2/VM600 system’s Tacho, Raw and

Open collector (OC) buses, and power supply

distribution

• Uses the VM600Mk2/VM600 RPS6U rack power

supply: AC and/or DC input versions

• Power supply check relay

APPLICATIONS

• VM600Mk2/VM600 machinery protection and/

or condition monitoring systems

DESCRIPTION

The VM600Mk2/VM600 ABE040 and ABE042 system

racks are used to house hardware for the

VM600Mk2/VM600 series of machinery protection

and/or condition monitoring systems, from

Meggitt’s vibro-meter® product line.

Two types of VM600Mk2/VM600 ABE04x system

rack are available: the ABE040 and the ABE042.

These are very similar, differing only in the position

of the mounting brackets. Both racks have a

standard height of 6U and provide mounting

space (rack slots) for up to 12 single-width

VM600Mk2/VM600 modules (card pairs), or a

combination of single-width and multiple-width

modules (cards). These racks are particularly

suitable for industrial environments, where

equipment must be permanently installed in 19″

cabinets or panels.

DESCRIPTION (continued)

The different versions of ABE04x system rack

enable different mounting options to support

various markets and applications.

The VM600 system rack has an integrated VME

backplane which provides the electrical

interconnections between the installed

VM600Mk2/VM600 modules (cards): power supply,

signal processing, input /output, relay and

CPUx “rack controller”. It also includes a power

supply check relay, available at the rear of the

rack, which is used to indicate that the installed

RPS6U rack power supplies are operating

normally.

Either one or two RPS6U rack power supplies can

be installed in a VM600Mk2/VM600 ABE04x system

rack. A rack with one RPS6U power supply (330 W

version) supports the power requirements for a full

rack of modules (cards) in applications with

operating temperatures up to 50°C (122°F).

Alternatively, a rack can have two RPS6U power

supplies installed in order to either support rack

power supply redundancy or in order to supply

power to the modules (cards) non-redundantly

over a wider range of environmental conditions

(see Power supply on page 4).

VM600Mk2/VM600 processing modules (cards) are

installed in the front of the rack and the

associated input/output modules (cards) are

installed in the rear. The input/output modules

(cards) provide connectors for the connection of

sensors/measurement chains and for the sharing

of various signals with external systems such as a

DCS or PLC.

In general, VM600Mk2/VM600 ABE04x system racks

are configured in the factory before delivery so

they are supplied ready-to-use. Optionally, each

module (card) can be reconfigured to meet the

needs of a particular machinery monitoring

application using the appropriate software

package from Meggitt vibro-meter®:

VM600 MPSx or VibroSight®.

For further information, contact your local

Meggitt representative.

General

Housing : Extruded aluminium frame and solid aluminium structural parts.

Top and bottom plastic guide strips for VM600Mk2/VM600 modules

(cards).

Colour : Aluminium

Power supply : The VM600Mk2/VM600 RPS6U rack power supply is used to provide

the VM600Mk2/VM600 rack itself and all installed modules (cards)

with +5 VDC and ±12 VDC.

See also Power supply on page 4.

Power supply inputs : Power supply inputs (associated rear panels) typically have an AC

and/or DC connector (with RFI filters), on/off switches and fuses.

Refer to the VM600Mk2/VM600 RPS6U rack power supplies

data sheet for information on power supply inputs, associated rear

panels and mains power supply leads (power cords).

Backplane : Proprietary VM600Mk2/VM600 rack buses (Tacho bus, Raw bus and

Open collector (OC) bus) for data/signal sharing between modules

(cards).

VME bus for communication between CPUx modules (cards) and

processing modules (cards).

General

Housing : Extruded aluminium frame and solid aluminium structural parts.

Top and bottom plastic guide strips for VM600Mk2/VM600 modules

(cards).

Colour : Aluminium

Power supply : The VM600Mk2/VM600 RPS6U rack power supply is used to provide

the VM600Mk2/VM600 rack itself and all installed modules (cards)

with +5 VDC and ±12 VDC.

See also Power supply on page 4.

Power supply inputs : Power supply inputs (associated rear panels) typically have an AC

and/or DC connector (with RFI filters), on/off switches and fuses.

Refer to the VM600Mk2/VM600 RPS6U rack power supplies

data sheet for information on power supply inputs, associated rear

panels and mains power supply leads (power cords).

Backplane : Proprietary VM600Mk2/VM600 rack buses (Tacho bus, Raw bus and

Open collector (OC) bus) for data/signal sharing between modules

(cards).

VME bus for communication between CPUx modules (cards) and

processing modules (cards).

Rack slots

(module (card) positions)

: Front of rack:

• 12 × slots – module (card) positions 03 to 14 – for processing

modules (cards) such as MPC4Mk2, XMx16, MPC4 and/or AMC8.

• 2 × slots – module (card) positions 00 to 01 – for rack controller

and communications interface modules (cards) such as CPUMMk2

or CPUx.

• 1 × slot – module (card) position 02 – reserved for applicationspecific modules (cards).

Rear of rack:

• Up to 19 × slots – module (card) positions 00 to 18 – for associated

input/output modules (cards) such as IOC4Mk2, XIO16T, IOC4T and/

or IOC8T, IOCNMk2 or IOCx, and relay modules (cards) such as

RLC16Mk2, RLC16 and/or IRC4.

• Up to 4 × slots – module (card) positions 17 to 20 – for associated

rear panels for inputs to the VM600Mk2/VM600 RPS6U rack power

supply or supplies.

See also Mechanical drawings – front and rear views on page 6.

Notes

In general, associated input/output modules (cards) are required

while relay modules (cards) are optional.

For safety reasons, any VM600Mk2/VM600 rack slot not populated

by a module (card) must be covered by a blank panel(s).

Rack slot number coding : For modules (cards) installed in the rear of an ABE04x rack, an

electronic keying mechanism known as slot number coding is used

to help ensure that the module (card) is installed in the correct slot,

as defined by the configuration (that is, by the VibroSight® or

VM600 MPSx software).

For ABE04x racks, the rack’s slot numbers are fixed (hard-wired) and

slot number coding requires that a module’s slot number is set to

match the rack slot (module (card) position) where it is installed.

Slot number coding range : 3 to 14

Slot number coding defaults : Fixed (hard-wired) as follows:

• Slot 03 = 3 (0011 binary)

• Slot 04 = 4 (0100 binary)

…

• Slot 13 = 13 (1101 binary)

• Slot 14 = 14 (1110 binary).

Galvanic separation : Galvanic separation units (GSIxxx) are available for accelerometer

and proximity systems mounted in explosive atmospheres. These

units cannot be supplied by the rack and require an external power

supply. They must be mounted outside the rack in a remote housing

or in a cabinet.

Power supply

VM600Mk2/VM600 RPS6U rack power

supplies

: A VM600Mk2/VM600 ABE04x system rack can have either one or

two RPS6U rack power supplies installed, as follows:

• 1 × RPS6U power supply (330 W) supports the power requirements

for a full rack of modules (cards) in applications with operating

temperatures up to 50°C (122°F).

• 2 × RPS6U power supplies (330 W) – operating redundantly –

supports the power requirements for a full rack of modules (cards)

in applications with operating temperatures up to 50°C (122°F).

With this rack power supply redundancy, if one RPS6U fails, the

other will provide 100% of the rack’s power requirements so that the

rack will continue to operate.

Note: This is known as a redundant RPS6U rack power supply

configuration.

• 2 × RPS6U power supplies (330 W) – operating non-redundantly –

supports the power requirements for a full rack of modules (cards)

in applications with operating temperatures above 50°C (122°F),

where RPS6U output power derating is required.

Note: Even though two RPS6U rack power supplies are installed in

the rack, this is not a redundant RPS6U rack power supply

configuration.

Refer to the VM600Mk2/VM600 RPS6U rack power supplies

data sheet and a VM600Mk2/VM600 machinery protection system

(MPS) hardware manual for further information.

Power supply check relay

Nominal switching capacity

(resistive load)

: 4 A / 250 VAC, 3 A / 30 VDC

Maximum switching power

(resistive load)

: 1000 VA, 90 W

Maximum switching voltage : ±30 VRMS / ±42.4 VAC(PEAK) or 60 VDC

Maximum switching current : 4 AAC, 3 ADC

Environmental

According to IEC 60068-2 recommendations

Temperature

• Operating : 0 to 70°C (32 to 158°F)

• Storage : −40 to 85°C (−40 to 185°F)

Humidity : 0 to 90%, non-condensing

Vibration : 10 to 55 Hz, 0.35 mm peak, 6 hours in each direction

Shock : 15 g peak, 11 ms, half-sine pulse

Indoor use : Limited to indoor use only

Approvals

Conformity : European Union (EU) declaration of conformity (CE marking).

CCSAUS certificate of compliance.

EAC marking, Eurasian Customs Union (EACU) certificate/

declaration of conformity.

Electromagnetic compatibility : IEC/EN 61000-6-2 and IEC/EN 61000-6-4.

TR CU 020/2011.

Electrical safety : IEC/EN 61010-1.

TR CU 004/2011.

Vibration : IEC 60255-21-1 (Class 2)

Environmental management : RoHS compliant

Russian federal agency for technical

regulation and metrology (Rosstandart)

: Pattern approval certificate OC.C.28.004.A N° 60224

Physical

Dimensions : See Mechanical drawings starting on page 4

Weight : 6.5 kg (14.3 lb) approx.

without RPS6U power supplies and modules (cards)

S

Type Designation Ordering number (PNR)

ABE040 Different versions of the VM600Mk2 ABE040 system rack:

– Standard version 204-040-100-016

ABE040 Different versions of the VM600Mk2/VM600 ABE040 system rack:

– Standard version 204-040-100-015

– Varnished version, with a conformal coating for additional

environmental protection 204-040-100-015L

– Separate circuits version, in accordance with the IEC 60255-5 standard 204-040-100-115

– CCSAUS version, in accordance with the IEC 61010-1 standard 204-040-100-214

ABE042 Different versions of the VM600Mk2/VM600 ABE042 system rack:

– Version with mounting brackets positioned at the rear of the rack 204-042-100-01h

– Varnished version, with a conformal coating for additional

environmental protection 204-042-100-01hL

Different blank panel kits for the front of a VM600Mk2 ABE04x system rack:

– 1 × slot wide / 4 HP (TE) 200-505-011-012

– 3 × slots wide / 12 HP (TE) 200-505-018-012

Different blank panel kits for the rear of a VM600Mk2 ABE04x system rack:

– 1 × slot wide / 4 HP (TE) 200-505-011-012

Different blank panel kits for the front of a VM600 ABE04x system rack:

– 1 × slot wide / 4 HP (TE) 200-505-015-011

– 2 × slots wide / 8 HP (TE) 200-505-016-011

– 3 × slots wide / 12 HP (TE) 200-505-018-011

– 4 × slots wide / 16 HP (TE) 200-505-017-011

Different blank panel kits for the rear of a VM600 ABE04x system rack:

– 1 × slot wide / 4 HP (TE) 200-505-011-011

– 2 × slots wide / 8 HP (TE) 200-505-012-011

– 4 × slots wide / 16 HP (TE) 200-505-013-011

Notes

In an ordering number (PNR), “h” represents the hardware version.

The standard version of the VM600Mk2 ABE040 system rack (PNR 204-040-100-016) and the standard version of the VM600Mk2/VM600

ABE040 system rack (PNR 204-040-100-015 or earlier) are the same, except for the specific artwork/branding/finish. More specifically,

the mounting brackets on the side of the ABE040 system rack are bare aluminium for the VM600Mk2 versions and painted for the

VM600Mk2/VM600 versions. See also Ordering guidelines on page 9.

For safety reasons, any VM600Mk2/VM600 ABE04x system rack slot not populated by a module (card) must be covered by a blank

panel(s).

(The width of a 19″ rack is typically measured in horizontal pitch (HP) units of 5.08 mm (0.2″), also known as standard width (TE) units.

For the VM600Mk2/VM600 ABE04x System racks, a 1 × slot wide blank panel suitable for covering one module (card) position

corresponds to 4 HP (TE), a 2 × slots wide blank panel corresponds to 8 HP (TE), a 3 × slots wide blank panel corresponds to 12 HP (TE)

and so on.)

When only one RPS6U power supply is installed in a VM600Mk2/VM600 ABE04x system rack (PS1 in rack slots 18 to 20), the unused

power supply position (PS2 in rack slots 15 to 17) should be populated with a blank panel(s).

ORDERING GUIDELINES

The ordering numbers (PNRs) given in Ordering information on page 8 of this data sheet should be used when

ordering a VM600Mk2/VM600 ABE04x system rack and/or blank panels as individual system components for use

as a replacement or spare part.

However, when ordering these components with other system components as part of a complete

VM600Mk2/VM600 machinery monitoring system, then a VM600SYS-based ordering number should be used.

Contact your local Meggitt representative for further information.

RELATED PRODUCTS

VM600Mk2 (second generation)

ABE056 VM600Mk2/VM600 slimline rack : Refer to corresponding data sheet

ASPS VM600Mk2/VM600 auxiliary sensor power

supply

: Refer to corresponding data sheet

CPUMMk2 + IOCNMk2 VM600Mk2 rack controller and

communications interface module

: Refer to corresponding data sheet

MPC4Mk2 + IOC4Mk2 VM600Mk2 machinery protection and

condition monitoring module

: Refer to corresponding data sheet

RLC16Mk2 VM600Mk2 relay module : Refer to corresponding data sheet

RPS6U VM600Mk2/VM600 rack power supplies : Refer to corresponding data sheet

XMx16 + XIO16T VM600Mk2/VM600 condition monitoring

modules

: Refer to corresponding data sheet

VibroSight VibroSight® machinery monitoring system

software

: Refer to corresponding data sheet

VM600 (first generation)

ABE056 VM600Mk2/VM600 slimline rack : Refer to corresponding data sheet

AMC8 and IOC8T VM600 analog monitoring card pair : Refer to corresponding data sheet

ASPS VM600Mk2/VM600 auxiliary sensor power

supply

: Refer to corresponding data sheet

CPUM and IOCN VM600 modular CPU card and

input/output card.

Note: With a front-panel display and support

for Modbus RTU/TCP or PROFINET.

: Refer to corresponding data sheet

CPUR and IOCR VM600 rack controller and communications

interface card pair.

Note: With rack controller redundancy and

support for Modbus RTU/TCP.

: Refer to corresponding data sheet

CPUR2 and IOCR2 VM600 rack controller and communications

interface card pair.

Note: With mathematical processing of

fieldbus data and support for Modbus TCP

and PROFIBUS.

: Refer to corresponding data sheet

IRC4 VM600 intelligent relay card : Refer to corresponding data sheet

MPC4 and IOC4T VM600 machinery protection card pair : Refer to corresponding data sheets

RLC16 VM600 relay card : Refer to corresponding data sheet

RPS6U VM600Mk2/VM600 rack power supplies : Refer to corresponding data sheet

XMx16 + XIO16T VM600Mk2/VM600 condition monitoring

modules

: Refer to corresponding data sheet

Meggitt (Meggitt PLC) is a leading international engineering company, headquartered in England, that designs and delivers high-performance

components and subsystems for aerospace, defence and selected energy markets. Meggitt comprises four customer-aligned divisions:

Airframe Systems, Engine Systems, Energy & Equipment and Services & Support.

The Energy & Equipment division includes the Energy Sensing and Controls product group that specialises in sensing and monitoring solutions for a

broad range of energy infrastructure, and control valves for industrial gas turbines, primarily for the Power Generation, Oil & Gas and Services markets.

Energy & Equipment is headquartered in Switzerland (Meggitt SA) and incorporates the vibro-meter® product line, which has over 65 years of sensor

and systems expertise and is trusted by original equipment manufacturers (OEMs) globally.

All information in this document, such as descriptions, specifications, drawings, recommendations and other statements, is believed to be

reliable and is stated in good faith as being approximately correct, but is not binding on Meggitt (Meggitt SA) unless expressly agreed in

writing. Before acquiring and/or using this product, you must evaluate it and determine if it is suitable for your intended application. You

should also check our website at www.meggittsensing.com/energy for any updates to data sheets, certificates, product drawings, user

manuals, service bulletins and/or other instructions affecting the product.

Unless otherwise expressly agreed in writing with Meggitt SA, you assume all risks and liability associated with use of the product. Any

recommendations and advice given without charge, whilst given in good faith, are not binding on Meggitt SA. Meggitt (Meggitt SA) takes

no responsibility for any statements related to the product which are not contained in a current Meggitt SA publication, nor for any

statements contained in extracts, summaries, translations or any other documents not authored and produced by Meggitt SA.

The certifications and warranties applicable to the products supplied by Meggitt SA are valid only for new products purchased directly from

Meggitt SA or from an authorised distributor of Meggitt SA.

In this publication, a dot (.) is used as the decimal separator and thousands are separated by thin spaces. Example: 12345.67890.

Copyright© 2022 Meggitt SA. All rights reserved. The information contained in this document is subject to change without prior notice

Leave a comment

Your email address will not be published. Required fields are marked *