1. Introduction

Description

An I/A Series Magnetic Flowmeter System consists of two major components:

IMT25 Magnetic Flow Transmitter with Version 2 Software

Magnetic Flowtube

8000A wafer body

2800, 8300, 9100A, 9200A, or 9300A flanged body

A system may be specified with the transmitter integrally mounted with the flowtube or with a

remote mounted transmitter, which can be mounted either on a pipe or a flat surface.

Your transmitter has one of three communication protocols.

One is a FoxCom communications protocol. The digital output signal in this version is used

for flowmeters serving as a primary measuring device in an I/A Series system. You can

communicate with this version via the I/A Series system, the PC-based Configurator, or the

optional local keypad/display.

Another has HART communications capability. You can communicate with this version via a

HART Communicator, PC-Based Configurator, or the optional local keypad/display.

The third has FOUNDATION fieldbus communication capability. You can communicate with

this version via a fieldbus host or the optional local keypad/display.

This document describes local operation, configuration, and calibration of an IMT25 Transmitter

supplied with local keypad and display. For information on operation, configuration, and

calibration from a PC-Based Configurator, a HART Communicator, or a FOUNDATION fieldbus

host refer to the documents listed in “Reference Documents” on page 13.

Intended Audience

This document is intended for use by process operators, engineers, and instrument technicians. If

you are interested only in operation, read the general information in the Introduction and the

chapter titled Operation. If you are interested in calibration, read the Introduction and chapters

titled Operation and Calibration. If you are concerned with configuration, read the entire manual,

with special emphasis on the chapter titles Configuration and the structure diagrams in

Appendix A and the configuration worksheets in Appendix B.

Functions

Using the IMT25 front panel keypad/display, the functions you can perform are:

Operating Functions

Display Measurement Information: The current value of the flow rate in engineering

units (EGU), flow rate in percent of upper range value (URV), the Forward Total,

Reverse Total, Net Total, and Grand Total.

Display the Status of the Transmitter: The current operating mode, Analog and Pulse

Output values, Contact Input settings, Relay Output settings, noise reduction,

AutoZeroLock information, and write protection as well as alarm and diagnostic

status.

Display Identity Information: Tag, description, and message plus identification data

for the flowmeter, flowtube, and transmitter software.

Acknowledge Alarms and Diagnostic Conditions.

Reset Totals.

Calibration Functions

NOTE

These functions can be passcode protected from keypad changes.

Adjust the 4 and 20 mA output signal (requires additional equipment)

Preset outputs to calibrate control loop

Calibrate the AutoZeroLock Detector

Configuration Functions

NOTE

These functions can be passcode protected from keypad changes.

Display and modify all configuration parameters

Assign passcodes and set levels of privilege

Reference Documents

This document addresses operation, configuration, and calibration using the local keypad/display

panel. For remote communication with your transmitter and other details of the flowmeter, refer

to the applicable documents listed in Table 1

2. Quick Start

FoxCom or HART Protocol

Your IMT25 Transmitter can be configured with a PC-Based Configurator or with the

keypad/display option. With the keypad/display, two configuration menus exist, Quick Start and

Setup. Most basic applications can be configured in Quick Start mode.

Quick Start mode can be used for applications requiring only:

A 4-20 mA output based on a flow rate in (US) GPM

The transmitter display to show a flow rate in (US) GPM

A FoxCom digital or HART flow rate signal.

Use Setup mode that is fully described in “Configuration” on page 39, for applications involving:

Transmitters powered from 50 Hz sources

Pulse and frequency outputs

Totalizer functions

Flow units other than (US) GPM

Alarm functions

Multi-range or bi-directional flow configurations.

To make Quick Start changes to the configuration, go to 1 TOP LEVEL/Quick Start by

pressing the Left arrow repeatedly until the display reads 1 TOP LEVEL. Then use the up/down

arrow keys to go to 1 TOP LEVEL/Quick Start. The procedure to change your configuration is

demonstrated by the following example:

Flowmeter factor of 18.22 (refer to “Determining the Meter Factor” on page 18)

Forward direction of flow

Flow Range 0 to 150 GPM

1. Use the Right arrow key to move to MFACTOR FORMAT? {###.######}. This format

can be changed, if necessary, to accommodate the meter factor.

a. If no change is required, press the Right arrow key.

b. To change the format, press Shift + Change to enter Edit Mode. Then use the

up/down arrow keys to step through the choices. When you reach the format you

want, press the Right arrow key.

2. The display reads METER FACTOR? {###.######} (Default {012.000000}). Press

Shift + Change to enter Edit Mode. Use the Right/Left arrow keys to move the

cursor under the digits you want to change. Use the up/down arrow keys to change

the digits to the desired values. In the case of this example, continue this procedure

until the display reads [018.220000]. Use the Right arrow key to move the cursor

out past the right bracket to save the setting. The display then reads METER FACTOR?

{018.219998}. Note that in some cases, as with this example, a slightly different

value will appear. The magnitude of this difference is insignificant. Press the Right

arrow key again.

NOTE

To determine the correct meter factor, refer to “Determining the Meter Factor” on

page 18.

3. The display reads RATE FORMAT? {#####.#} This format can be changed, if

necessary, to accommodate your flow rate.

a. If no change is required, press the Right arrow key.

b. To change the format, press Shift + Change to enter Edit Mode. Then use the

up/down arrow keys to step through the choices. When you reach the format you

want, press the Right arrow key.

4. The display reads FORWARD URV? {#####.#} (Default {00100.0}). Press Shift +

Change to enter Edit Mode. Use the Right/Left arrow keys to move the cursor under

the digits you want to change. Use the up/down arrow keys to change the digits to the

desired values. In the case of this example, continue this procedure until the display

reads [00150.0]. Use the Right arrow key to move the cursor out past the right

bracket to save the setting. The display then reads FORWARD URV? {00150.0}.

5. Now that all changes have been made, press the Right arrow key. You are asked Go

On-Line? Reply Yes by pressing the Right arrow key. Press the Right arrow key again

to begin displaying flow measurements.

Foundation Fieldbus Protocol

Your transmitter has been preconfigured at the factory to the settings shown in Appendix B.

Compare your needs to the factory configuration and note the changes to the configuration you

must make.

If the transmitter is not connected to a flowtube or IMTSIM, it is necessary to put a jumper wire

between terminals Coil 1 and Coil 2 and also to provide power to the transmitter.

This section describes the procedures to quick start the transmitter from the optional local

keypad/display. Note that after you quick start the transmitter from the local keypad, you should

use the fieldbus host to ensure that parameter values associated with the host are changed to agree

with those changed from the local keypad/display. Otherwise, mismatch errors occur when you

attempt to place the transmitter into Auto mode.

To make changes to the configuration using the local keypad/display, go to 1 TOP LEVEL/Setup

by pressing the Left arrow repeatedly until the display reads 1 TOP LEVEL. Then use the

Up/Down arrow keys to go to 1 TOP LEVEL/Setup. The procedure to change your

configuration is demonstrated by the following example:

Engineering units (EGUs) in GPM (factory default setting)

Forward direction of flow (Unidir positive – factory default setting)

Flow range 0 to 150 GPM

Flowmeter factor of 18.22 (refer to “Determining the Meter Factor” on page 18)

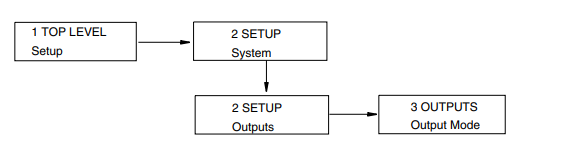

- Note that the factory default engineering units is already configured as GPM, so no change is required. 2. Note that the factory Output mode is also already configured as UniDir positive, so no change in the direction is required. 3. You must enter your flow upper range value however. To do this: a. Go to Setup Level 2 by pressing the Right arrow key. Next move to 2 SETUP Outputs with the Down arrow key. Then move to 3 OUTPUTS Output Mode with the Right arrow key

b. Use the Down arrow key to go to 3 OUTPUTS Range Info and the Right arrow

key to go to FORWARD URV? {#####.#} GPM (Default {00100.0}).

c. Press the Shift + Change keys to enter Edit mode. You are asked Go Offline?

Reply Yes by pressing the Right arrow key. The display shows FORWARD URV?

[#####.#] GPM.

d. Use the Right/Left arrow keys to move the cursor under the digits you want to

change. Use the Up/Down arrow keys to change the digits to the desired values. In

the case of this example, continue this procedure until the display reads

[00150.0].

e. Using the Right arrow key, move the cursor under the right bracket and press the

key to enter the URV. The display reads FORWARD URV? {150.0} GPM.

f. Press the key again to move back to 3 OUTPUTS Range Info.

4. Lastly, you have to enter your flowmeter factor. To do this:

a. Use the Left arrow key to move to the Level 2 menu, 2 SETUP Outputs.

b. Press the Down arrow key six times to move to 2 SETUP Calibration and the

Right arrow key to move to the Level 3 menu, 3 CALIBRATION Meter Factor.

See FIgure A-5.

c. Use the Right arrow key to move to MFACTOR FORMAT? {###.######}. This

format can be changed, if necessary, to accommodate the meter factor.

d. Use the Right arrow key to move to METER FACTOR? {###.######} (Default

{012.000000}. Then press Shift + Change to enter Edit mode.

e. Use the Right/Left arrow keys to move the cursor under the digits you want to

change. Use the Up/Down arrow keys to change the digits to the desired values. In

the case of this example, continue this procedure until the display reads

[018.220000]. Use the Right arrow key to move the cursor out past the right

bracket to save the setting. The display then reads METER FACTOR?

{018.219998}. Note that in some cases, as with this example, a slightly different

value appears. The magnitude of this difference is insignificant.

NOTE

To determine the correct meter factor, refer to “Determining the Meter Factor” on

page 18.

f. Press the Right arrow key again. The display reads 3 CALIBRATION Meter

Factor.

5. Now that all changes have been made, press the Left arrow key until you are asked Go

On-Line? Reply Yes by pressing the Right arrow key. To display flow measurement,

press the Right arrow key once more.

! CAUTION

If you change the upper range value or engineering units in the Transducer Block with

the local display pushbuttons without making a corresponding change in the

corresponding Analog Input Blocks from a fieldbus host, a mismatch error occurs and

the Analog Input Block reverts to Out of Service mode.

Determining the Meter Factor

First find the “Cal Factor” or “IMT25 Cal Fact” on the flowtube data label.

If the flowtube data label has a “IMT25 Cal Fact.” listing, use that value as the “Meter Factor.”

If only a “Cal Factor” value is found on the flowtube data label, that value must be multiplied by

the appropriate factor from Table 2 to calculate the “Meter Factor.”

Operation from Keypad/Display Panel

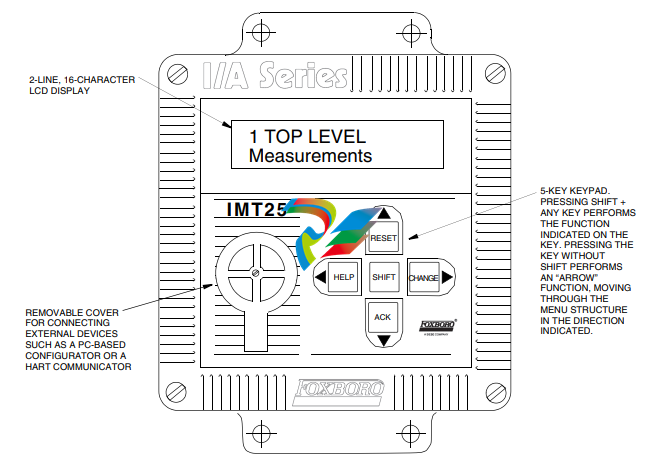

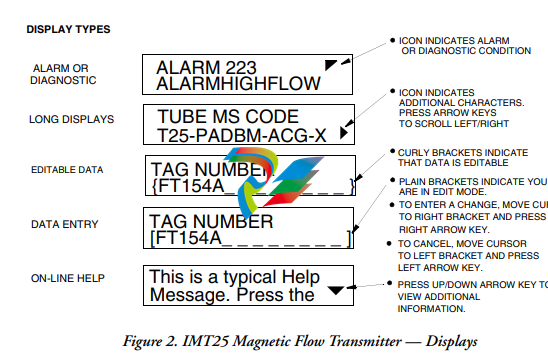

For local operation, configuration, and calibration, all operator entries are made through a

5-button keypad and all data is presented on a 2-line x 16 character LCD display. The

keypad/display of the IMT25 Transmitter is shown in Figure 1. Information on various types of

display is shown in Figure .

Figure 1. IMT25 Magnetic Flow Transmitter — Keypad/Display

All required functions are accomplished by using the four arrow keys alone and in combination

with the Shift key. Table 4 explains the function of each key

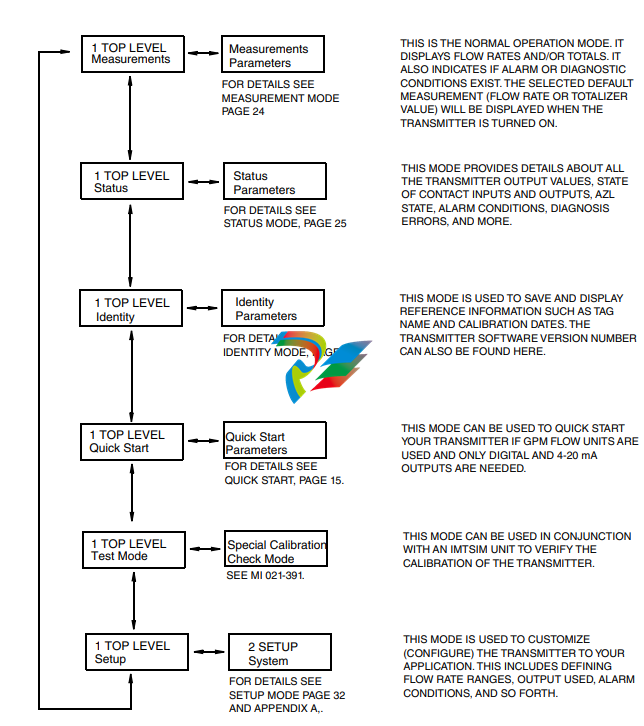

Top Level Menu

The Top Level menu displays the following modes – Measurements, Status, Identity, Quick Start

(in FoxCom and HART transmitters), Test Mode, and Setup. You can switch from one to another

in sequence by using the Up/Down arrow keys. To enter the second level menu from a particular

top level screen, press the Right arrow key. To return to the top level from a second level menu

item, press the Left arrow key. The level of the first, second, third, and fourth level menus is

indicated by the digit appearing as the first character in Line 1 of the display; a 1 indicates Level 1

(Top Level), a 2 indicates Level 2, and a 3 indicates Level 3, etc.

The top level menu is shown in Figure 3. For a complete presentation of all menu structures, refer

to Appendix A.

Measurements Mode

The Measurements mode, which is your main operating mode, is displayed upon startup.

Depending on the transmitter configuration, it has up to seven displays, any of which may be set

as the startup default. All screens can be scrolled with the Up/Down arrow keys.

Rate (EGU) — Shows current flow rate (forward or reverse) in the selected

engineering units.

Rate (% Range) — Shows current flow rate (forward or reverse) as a percentage of full

scale URV.

Fwd Tot — Shows current value of the forward totalized flow in engineering units.

Use the Net Tot display to reset.

Rev Tot — Shows current value of the reverse totalized flow in engineering units. Use

the Net Tot display to reset.

Net Tot — Shows current value of the net totalized flow (forward total – reverse total)

in selected engineering units. Press Shift + Reset to reset the displayed total to

zero. Resetting Net Tot also resets Fwd Tot and Rev Tot. It does not reset Gr Tot.

If Reset Totals is passcode protected, the message Enter Passcode appears.

Grand Tot — Shows current value of the grand total flow in engineering units. Press

Shift + Reset to reset the displayed total to zero. Resetting Gr Tot does not reset

Fwd Tot, Rev Tot, and Net Tot. If Reset Totals is passcode protected, the message

Enter Passcode appears.

If the Dual Display feature is configured On, a combination of two of these parameters can be

displayed at once. A typical dual display, in which Line 1 shows flow rate and Line 2 shows the

present forward total, is shown below. Units may not be displayed or may be truncated.

You may step through the displays of each of these parameters with the Up and Down arrow keys.

However, unless you specifically do so, the display defaults to that configured in Setup mode. The

engineering units and formats used in the displays are also configured in Setup mode.

Status Mode

The Status mode enables you to view fourteen system parameters and thus assess the performance

of the loop. You may not edit them in this mode. To step through the displays of the following

parameters, use the up/down arrow keys:

Mode — Shows the present operating mode: On-Line, Off-Line, Override, or

Calibrate. This will normally display On-Line. The other modes will only be

displayed if someone else has changed the mode with an I/A Series Workstation,

PC-Based Configurator, HART Communicator, or fieldbus host. Off-Line means

that it has been taken off-line; Override, that the measurements cannot be relied

upon because one or more of the outputs is at a preset value; and Calibrate, that the

transmitter is in Calibration mode.

Alarm — Shows the most current active alarm. If there are no active alarms but

something is in the history buffer, the display reads Alarms In Buffer. If there are

no active alarms and nothing in the buffer, display reads No Alarms.

Diagnostics — Shows No Diag, Diag Existed, or Diag Exists. If a diagnostic

problem exists, the second line identifies the problem. Help is available with the

Shift + Help keys. An active diagnostic problem cannot be cleared; the problem

must be corrected. Diag Existed means a diagnostic error did occur, but the

condition has cleared and the transmitter is working correctly. However, the Diag icon

will remain on the display until the diagnostic has been acknowledged. To clear, the

transmitter must be in the Status mode with the diag window displayed. Then use the

Shift + Ack keys.

Digital Output — If the transmitter output is in Digital Output mode, the display

shows whether the transmitter is configured for Unidirectional or BiDirectional flow.

If the transmitter is not in Digital Output mode, the screen is not displayed.

NOTE

Digital and Analog Output are mutually exclusive. Only one of the two are displayed

at any one time.

Analog Output — If the transmitter output is in Analog Output mode, the display

shows whether the transmitter is configured for U (unidirectional), U/M1

(unidirectional multirange-range 1), U/M2 (unidirectional multirange-range 2, U/M3

(unidirectional multirange-range 3), B/D (bidirectional dual range), or B/S

(bidirectional split range). If the transmitter is not in Analog Output mode, the screen

is not displayed.

NOTE

Digital and Analog Output are mutually exclusive. Only one of the two are displayed

at any one time.

Table 5. Analog Output Configuration

Display Interpretation

U UniDirectional Flow Single Range

U/M1 UniDirectional Flow Multi-Range

Range 1 Active

U/M2 UniDirectional Flow Multi-Range

Range 2 Active

U/M3 UniDirectional Flow Multi-Range

Range 3 Active

B/D BiDirectional Flow Dual Range

B/S BiDirectional Flow Split Range

(mA reading less than 12 indicates reverse flow, greater than 12,

positive flow)

**UNKNOWN** Multi-Range is configured, but both contact inputs used to select

the active range are in inactive state

AZL Detect (Empty Pipe Det) — The intent of the AutoZeroLock Detection

(Empty Pipe Detection) feature is explained in “AutoZeroLock (Empty Pipe)” on

page 53.

If the AutoZeroLock (Empty Pipe) detector is configured On, the display shows:

EPD Inactive, EPD Active, or EPD Needs Setpnt (FoxCom)

AZL Inactive, AZL Active, or AZL Needs Setpnt (HART)

Inactive, Active, or AZL Needs Cal (Fieldbus).

When AZL (EPD) is active, the outputs are locked at zero. If AZL (EPD) is

configured Off, the status display shows Off.

! WARNING

Do not take any action that can cause danger to personnel or damage to equipment

based on the assumption that a pipe is empty or full because of an AutoZeroLock

(Empty Pipe Detection) indication.

AZL Count (Empty Pipe Cnt) — Shows the cumulative count (maximum of 255) of

AZL (empty pipe) conditions that have occurred since the last reset. To reset the

count to zero, press Shift + Reset Note that in some cases several counts may

occur for one emptying of the pipeline.

Noise Reduction — Shows whether the noise reduction function is configured On or

Off.

Write Protection — Shows whether the Write Protection dip switch is in the On position so that

no Setup (configuration) changes may be made. This feature is usually only used in custody

transfer applications or for another reason that you want to assure that the configuration is not

changed. For the procedure to change the setting of this switch, see MI 021-387.

Leave a comment

Your email address will not be published. Required fields are marked *