INTRODUCTION

The PSU830 power supply is intended for use in MX/ZX/

ZXF/T2000/MX2 fire panels. It is a functional replacement for the PSB800, PSM800, PSB820 and PSB821.

The PSU830 provides the following features:

Power factor correction (PFC) to minimise loading

effects on the AC supply and allows operation from 120

– 240V ac.

Temperature compensated, battery charger for sealed

lead acid batteries:

Battery disconnection (load shed) when operating from

battery supply to provide deep discharge protection to

battery set

Fault monitoring includes:-

– battery disconnected, battery wiring short, battery

high resistance, battery voltage low, battery reverse,

temperature compensation fault, ac supply low,

internal charger fault

Common fault output – volt free relay contacts

Diagnostic LEDs for

– AC ok

– Battery fault

– Charger fault

– Ground (earth) fault

Two 27VDC fused field supply outputs with short circuit

protection, one output may be reset (turned off) under

command from fire panel

40VDC 2.2.A output for supplying up to 4 fully loaded

MX Digital loops, typically a single PSU830 may

replace two PSB800 40V 1.2A supplies

5VDC output for use within fire panel/repeater

Selectable Ground (earth) fault monitoring

Battery charging function of two PSU830 may be connected in parallel

TECHNICAL SPECIFICATION

The PSU830 complies with the requirements of:

EN 54-4/1997:A2-2006 Fire Detection and fire alarm

systems; part 4, Power supply equipment

SYSTEM COMPATIBILITY:

Use only with MX/MX2/ZX/ ZXF/T2000 Fire Alarm

Controllers

ENVIRONMENT

Indoor Application only, Land and Marine

Operating Temperature: -10o

to +55oC

Storage Temperature: -20o to +70oC

Operating Humidity: Up to 95% non-condensing

DIMENSIONS (HWD):

62 x 132 x 242mm

EMC

The PSU830 complies with the following:

Product family standard EN50130-4 in respect of Conducted Disturbances, Radiated Immunity, Electrostatic

Discharge, Fast Transients and Slow High Energy

EN 61000-6-3 for Emissions

ELECTRICAL CHARACTERISTICS

Input Voltage: 120-240Vac 50/60Hz (autoranging)

Input Current Rated Load: 0.8-2.2ARMS

Rated input power: 200W maximum

Fig. 1: PSU830 power supply and battery charger

NOTICE

Sealed lead acid batteries cannot be reliably

charged when ambient air temperature

around them (the battery ambient) exceeds

50° C.

Outputs

– Non-reset:

27V dc @ 2A

5V dc @ 2.2A Rated, 3.0A max

40V dc @ 2.2 Rated, 2.3A max

– Reset: 27V dc @ 2A

+27V: 21-28.8Vdc (typically 27.3V with battery fully

charged)

+40V: 39.5-40.3Vdc

+5V: 4.8-5.25Vdc

Rated Output

Rated output of 5A to supply the panel, fire system

loads and charge 24V battery. De-rate to 4.5A when

used at 120VAC and ambient above 40ºC, e.g. some

T2000 Marine applications.

Maximum Alarm current 5A for 30 minutes

Maximum continuous load current (excluding charging) 2.5A

Rated output power: 136W

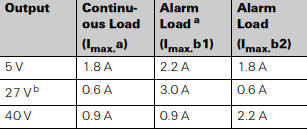

The PSU830 cannot support all outputs fully loaded, the

following output load combinations are possible in MX

panel application:

BATTERY CHARGER

A PSU830 may be used to charge 17Ah or 38Ah battery

sets. To meet the requirements of charge to 80% rated

capacity within 24 hours with a 38Ah battery set it is recommended that 2A or greater be allocated for battery

charging. Points to note:

Trickle charge determined by battery capacity, typically

100mA at 27.3Vdc.

Maximum charging voltage 28.8V, battery at -5ºC.

Minimum charging voltage 21V, condition battery discharged.

Deep discharge protection, battery disconnection voltage < 20V.

The PSU830 is not recommended for use with batteries

that have been deep discharged.

Recommended temperature for charging battery -5 to+

40ºC measured in the battery housing with thermistor lead

assembly within 2cms from battery. Sealed lead acid batteries cannot be reliably charged when ambient air temperature around them (the battery ambient) exceeds 50ºC.

Two PSU830 may be connected in parallel (dual PSU configuration) to provide charger output of up to 10A. All other

outputs remain separate, i.e. 2 x 5V, 4 x 27V, 2 x 40V and

must not be connected together. To meet the requirements

of charge to 80% rated capacity within 24 hours with a

65Ah battery set it is recommended that 3.4A or greater

be allocated for battery charging.

BATTERY REQUIREMENTS

17Ah or 38Ah single PSU830.

38Ah dual PSU830. Do not charge 17Ah batteries with

dual PSU830s.

Standby Current Consumption: 90mA @ 24V dc

FAULT MONITORING AND RESPONSE

FAULT CONDITIONS THRESHOLDS

Low AC, < 100VAC.

Battery low <22VDC

Battery disconnect < 20VDC

Battery High Resistance:

– Single PSU: 0.6Ω

– Dual PSU: 0.3Ω

This is the maximum resistance of the battery circuit including battery, wiring and connections to the charger.

Earth (ground fault), operates on the 0V, 5V, 27V and

40V rails. Sensitivity varies with rail with respect to

earth

– 40V and Loop SIG < 300kohm

– 27V < 100 kohm

– 0V and Loop RTN < 22kohm

DESIGN PLANNING

Cables are to be selected in accordance with Publication

17A-02-D and the requirements of local regulations/ code

of practise.

All the terminals at CON3 will accept cable up to 2.5mm2.

To comply with EN54.2 and EN54.4 it is recommend that

the batteries are installed in housing adjacent to the

PSU830 and not further than 2 metres from it. All cabling

between the PSU830 and the batteries housings must be

protected, preferably with metal conduit, in order to provide

adequate mechanical and EMI immunity.

Battery resistance fault monitoring includes the connecting

leads, < 0.1ohm, cabling must be used. The battery temperature thermistor lead assembly may be extended if

required, thermistors must not be swapped between units.

The PSU housing must be positioned so that convection

cooling is unrestricted. For installations where this is not

possible, e.g. installing T2000 fire panel into a console

would require fan cooling of the console and/or large apertures in the T2000 housing to assist cooling of the fire

panel within the console.

If DC units 8800 is exceeded then a second PSU830 is

required this provides power to the second and third

XLM800 and is connected the same way as a PSB800

supplied with PSB800K.

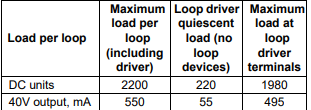

USING PSU830 WITH MX

DESIGNER

Fire panels using modules FIM802 and XLM800 the MX

Digital addressable loop load is defined in MX Designer,

summary below:

In early versions of MX Designer only PSB800 is available.

When PSB800 is selected it is possible to determine

PSU830 power supply loading as each loop may be loaded

above the DC units Red warning value, provided that the

value does not exceed 2200 DC units per loop and 8800

DC units per PSU830. The voltage drop and AC units Red

warning values stay the same and cannot be ignored. This

means that in many situations a single PSU830 can be

used where previously a combination of PSB800 and

PSB800K were required.

DUAL PSU

In dual PSU configuration only the charger outputs of the

PSU830 are in parallel, all other outputs remain separate,

i.e. 2 x 5V, 4 x 27V, 2X 40V and must not be connected

together. For optimum operational life the panel loading

should be divided equally between the PSU830s wherever

possible (although not essential). MX Designer may be

used to assist in loading of the PSU830.

For dual PSU configuration 0V connection between units

must be made in addition to BT+ and BT-. Cable assembly

must be fitted between CON6 on each unit to provide fault

monitoring. It is necessary to use PTM800 to provide wiring interconnect terminal block from the auxiliary PSU830

to loads such as XLM800.

17Ah battery set must not be connected in dual PSU configuration due to possibility of overcharging.

PRODUCTS REQUIRED FOR

INSTALLATION OF SECOND

PSU830

All items required for installation of second PSU830 are

available using FG number 557.202.044 PSU830K.

PSU830K consists of the following items:

557.202.210 PSU830 Power Supply

557.201.232 PTM800 Power Terminal Module

557.201.231 PSU830 Dual Power Supply Kit

INSTALLATION, GENERAL POINTS

For MX2, ZX4, ZX4BB panels the second (auxiliary)

PSU830 is installed on top of the first (primary)

PSU830.

For MX4000 and MX4000BB, panels the auxiliary

PSU830 is installed in the battery housing. The distance between the housings is constrained by the length

of the interconnecting cables. The recommended

installation is battery housing beneath fire panel.

Connection of primary and auxiliary AC power leads is

via a distribution block supplied with kit 557.201.231.

The external AC supply is connected to a socket which is

mated with distribution block.

If FB800 fuseboard is required it may be mounted on

small chassis plate above the batteries or on top of auxiliary PSU830, if the latter then PTM800 must be

mounted on the side of the PSU830.

The PTM800 should be mounted on the top of the

PSU830 for MX4000 and MX4000BB panels. For

ZX4 and ZX4BB it can either be mounted on top or on

the left hand side with restricted access. For MX2 it

would be sited on the left hand side.

For the ZX4 and ZX4BB panels, nylon cable ties are

required to attach the distribution block to the metal

bracket inside the panel housing.

Monitoring of the auxiliary PSU830 is provided by ribbon cable connected between both power supplies.

Battery capacity must not be less than 38Ah when dual

PSU830 is used as there is possibility of overcharging

with smaller capacity batteries.

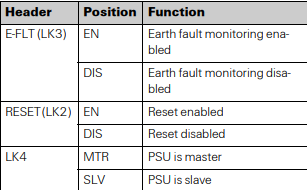

CONFIGURATION

HEADERS AND LINKS

The PSU830 has three headers to which are fitted jumper

links, these headers enable selection of the following:

Earth (ground) fault monitoring, there can only be one

Earth fault monitoring circuit active at the fire panel.

Output CON3.2 +27V may be reset (turned off) under

CIE control.

Unit may be configured for single unit or dual unit operation, link selects between primary (master) and auxiliary (slave). There can only be one primary and one auxiliary connected together, no other combinations are

permitted. PSU830 cannot be mixed with any other

PSU.

Refer to Table 3, 4 and Figs. 2, 3, 4 for details of terminal

block CON3, header and wiring configurations.

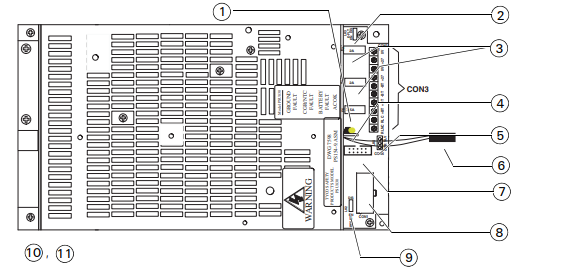

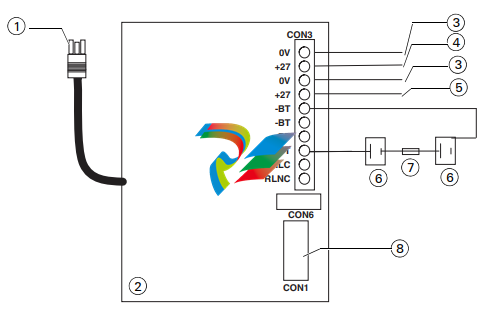

Fig. 2: PSU830 connectors, terminals and links

1 – Battery fuse

2 – Link 3

3 – 27V output fuses

4 – Diagnostic LEDs

5 – Link 4

6 – Battery temperature compensation cable and thermistor

7 – CON6 to CON6 of other PSU830 (dual PSU830 application)

8 – CON1 to FIM 802 PL2 or PTM800 if second PSU830

9 – Link 2

10 –LINK SETTINGS PRIMARY PSU830

LINK 2 (LK2, RESET_ – DIS (disable)

LINK 3 (LK3, E-FLT) – EN (enable)

LINK 4 (LK4) – MTR (master)

11 –LINK SETTINGS AUXILIARY PSU830

LINK 2 (LK2, RESET) – DIS (disable)

LINK 3 (LK3, E-FLT) – DIS (disable)

LINK 4 (LK4) – SLV (slave)

TYPICAL WIRING ARRANGEMENTS OF PSU830

Fig. 3: PSU830 typical wiring of primary power supply

1 – AC power input

2 – Primary PSU830

3 – DC common

4 – +27.3V DC (reset)

5 – +27.3V DC (standard)

6 – 38Ah 12 volt DC batteries

7 – Fuse-lead

8 – To FIM802

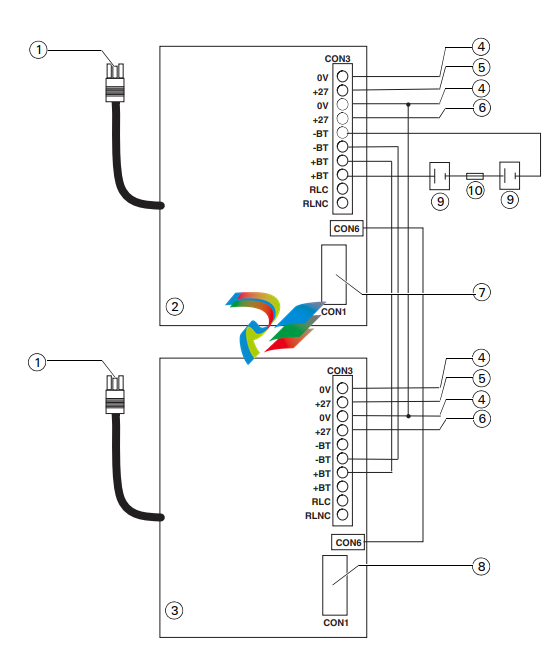

Fig. 4: Wiring for primary and auxiliary PSU830

1 – AC power input

2 – Auxiliary PSU830

3 – Primary PSU830

4 – DC common

5 – +27.3V DC (reset)

6 – +27.3V DC (standard)

7 – To PTM800

8 – To FIM802

9 – 38Ah 12 volt DC batteries

10 –Fuse-lead

OPTIONS

FB800

The fuseboard FB800 provides 8 fused outputs, it is connected to one of the 27V outputs of the PSU830. On the

cover of the PSU830 there are four M3 tapped holes to

accept the male/female threaded pillars supplied with the

FB800.

PTM800

The PTM800 provides screw terminals for 40V, 27V and

5V supplies, necessary when second PSU830 is used to

supply loop power to XLM800s. The 5V, 27V and 40V outputs are not fuse protected. The PTM800 is connected to

the PSU830 via 12 way cable assembly. It is mounted by

four plastic pillars and two 5/8 inch 4/40 UNC screws supplied with the PTM800. The PTM800 may be mounted

on top or on the left hand side of the PSU830.

SERVICE REPLACEMENT

PSU830 is a NOT a form fit replacement for PSB800,

PSM800 or PSB820, refer to publication 120.415.990

for service replacement instructions.

PSU830 should not be used with 10Ah battery sets due to

possibility of overcharging.

ORDERING INFORMATION

PSU830 Power Supply and Battery Charger:

557.202.210

PTM800 Power Terminal Module: 557.201.232

PSU830K Power Expansion Kit: 557.202.044

RELATED DOCUMENTATION

120.415.990 PSU830 Power supply and battery charger

installation and service replacement instructions.

120.415.984 Installation guide – PSU830 Dual Power

Supply kit.

CON1 CONNECTION

Mini blade fuses Farnell RS

2A: 994-3811 219-3536

7.5A: 994-3854 220-0892

Leave a comment

Your email address will not be published. Required fields are marked *