The Field Control Processor 280 is a distributed, optionally fault-tolerant, field-mounted controller that

performs process control and alarming functions according to a user-defined control strategy.

FEATURES

Performs regulatory, logic, timing, and sequential

control together with connected Fieldbus

Modules (FBMs)

Performs data acquisition and alarm detection

and notification

Supports up to 128 Compact or standard

200 Series FBMs, or up to 128 of a combination

of 100 Series FBMs and 200 Series FBMs (with

no more than 64 100 Series FBMs in this

configuration)

No Fieldbus Communication Module is required.

No Fieldbus Expansion Module is required for

Expanded fieldbus support.

Supports self-hosting mode, which allows the

FCP280 to boot itself with a valid control

database even without its host workstation

Offers unique, patented, fault-tolerant operation

using two control modules to greatly improve

reliability relative to other process controllers

Offers on-line image upgrade (OLUG) of a faulttolerant FCP280 without shutting down the

process

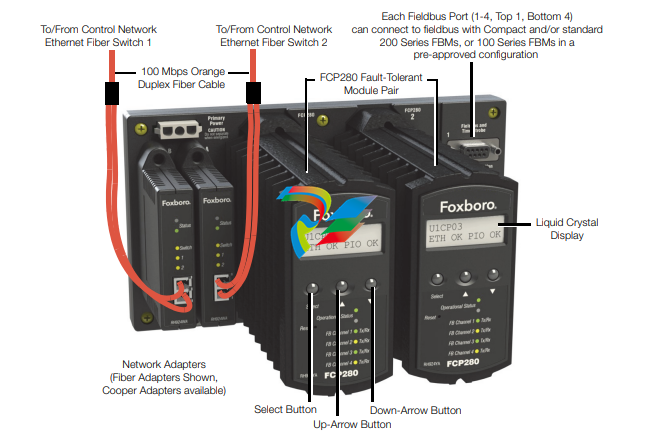

Liquid Crystal Display (LCD) displays letterbug

and real-time roles and statuses

Connects to The Mesh control network via

standard fiber optic or copper 100 Mbps

Ethernet cables

Uses a rugged, die cast aluminum housing for

mounting in a non-vented field enclosure

Can operate in Class G3 harsh environments

CE certified for field mounting in enclosures

Each Fieldbus port on FCP280 baseplates

supports either a 2 Mbps or 268 Kbps HDLC

fieldbus exclusively

Uses versatile control algorithms and a wide

variety of FBMs to provide control capabilities for

a broad range of process applications

Supports time synchronization using optional

external time from GPS satellites

Uses soft letterbugs configurable via the keys on

the FCP280 faceplate.

OVERVIEW

The Field Control Processor 280 (FCP280) is a

distributed, optionally fault-tolerant, field-mounted

controller module. The FCP280 performs regulatory,

logic, timing, and sequential control together with

connected Fieldbus Modules. It also performs data

acquisition and alarm detection and notification.

The FCP280 connects to The Mesh control network

via standard fiber optic or copper 100 Mbps Ethernet

cables from network adapters installed on its

baseplate (shown in Figure 1).

The FCP280 requires Foxboro Evo Control Core

Services v9.0 or later. A system with the FCP280 and

this software is called a Foxboro Evo Process

Automation System

Figure 1. Fault-Tolerant FCP280 Module Pair Mounted on Vertical Mounted 2-Position FCP280 Baseplate

The fault-tolerant version of the FCP280 consists of

two processor modules. These modules are installed

in adjacent FCP280 slots in a baseplate for high

speed communication between the modules.

The FCP280 accepts four PIO channels (that is, four

separate HDLC fieldbuses) via the four Fieldbus ports

on its baseplate. These four Fieldbuses are referred

to collectively as the “Expanded fieldbus.” For a

description of the FCP280 baseplates, refer to DIN

Rail Mounted Modular Baseplates

(PSS 21H-2W6 B4).

The number of FBMs which an FCP280 can support

varies depending on the types of FBMs used:

200 Series FBMs exclusively used with FCP280 –

Each Fieldbus port on the FCP280 baseplate can

connect to a baseplate chain with up to 32

Compact or standard 200 Series FBMs per chain

via the 2 Mbps HDLC fieldbus (up to 128

modules).

200 Series and 100 Series FBMs (dual baud

configurations) used with FCP280 – The FCP280

can support a total of 64 100 Series FBMs (Ymodule) or competitive devices (such as Foxboro

Evo System migration FBMs) in one or more

baseplate chains, with the remainder of the

FCP280’s 128 module limit being 200 Series

FBMs, depending on the Fieldbus loading of the

FCP280. For example, an FCP280 could support

64 100 Series FBMs and 64 200 Series FBMs (as

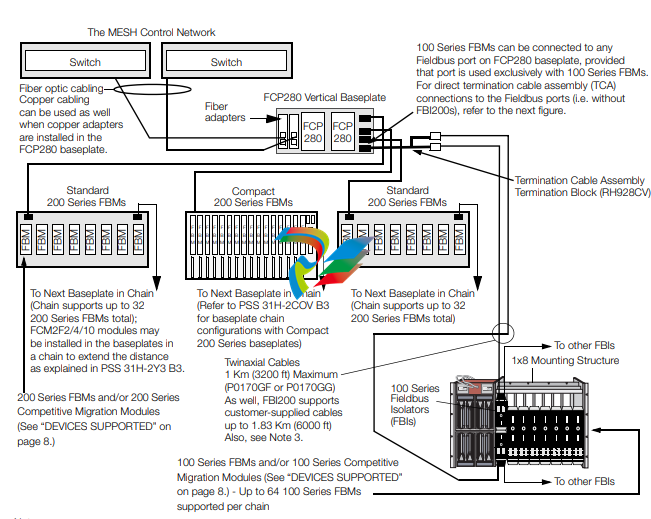

128 – 64 = 64). See Figure 2 and Figure 3 below.

NOTE

Certain competitive migration or supported

third-party modules such as DCS Migration

fieldbus Modules and Pepperl+Fuchs™ I/O

modules may increase this 128 module

maximum per FCP280. For the maximum

numbers of each of these migration/thirdparty modules supported by the FCP280,

refer to the supported migration products

books in Field Control Processor 280

(FCP280) User’s Guide (B0700FW).

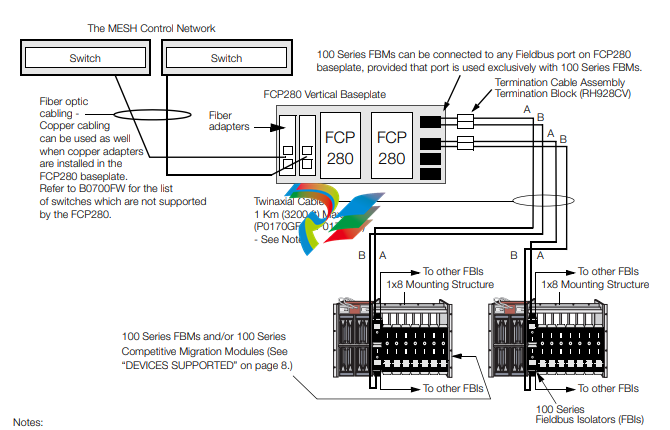

When supporting 200 Series and 100 Series FBMs,

each Fieldbus port (PIO channel) is dedicated to

supporting either a 268 Kbps HDLC fieldbus (for

100 Series FBMs) or a 2 Mbps HDLC fieldbus (for

200 Series FBMs) – not both.

For connections to 100 Series FBMs over 60 m

(198 ft), an FBI200 pair is required to extend

communications up to 1830 m (6000 ft). See

Figure 2 below.

To connect a Fieldbus port to a 268 Kbps HDLC

fieldbus directly, the Fieldbus splitter (RH928CV)

provides a connector for any Fieldbus port on the

FCP280 baseplate, and two Termination Cable

Assembly (TCA) termination blocks for the twinaxial

cabling from the 100 Series FBMs.

The FCP280 can also communicate with serial and

Ethernet devices, such as PLCs, via Field Device

System Integrators. This allows you to connect to

new device interfaces without any changes to the

controller software.

To estimate the FCP280’s processor load, refer to

Field Control Processor 280 (FCP280) Sizing

Guidelines and Excel Workbook (B0700FY)

FIBER AND COPPER NETWORK ADAPTERS

FCP280 modules connect to a pair of fiber or copper

adapters (see Figure 4) which each connect to one

Ethernet switch in The Mesh control network. The

FCP280 baseplate passes inbound traffic from either

of the two switches to both FCP280s, and pass

outbound traffic from the primary FCP280 module to

either switch.

Figure 4. Fiber Optic and Copper Network Adapters

The fiber or copper adapters mount on the FCP280

baseplate as shown in Figure 1 on page 2. They

receive their power from the baseplate.

REMOTE MOUNTING

The FCP280 simplifies the Foxboro Evo Process

Automation System architecture, maintaining control

while only requiring housing (via field enclosures),

host workstations with Foxboro Evo Control Core

Services v9.0 or later, and Ethernet switches for

communication via The Mesh control network

architecture, described in PSS 21H-7C2 B3.

The field-mounted FCP280 is an integral part of the

highly-distributed control network where controllers

are closely aligned to specific process units mounted

in close proximity to their I/O and the actual

equipment being controlled. Coordination between

process units takes place via a fiber optic 100 Mbps

Ethernet network.

The FCP280 and its network adapters are packaged

in a rugged, die cast aluminum housing that does not

require venting due to its efficient design. The

FCP280 and its network adapters are CE certified,

and it can be mounted without expensive special

cabinets to prevent electronic emissions. The

FCP280, network adapters, and baseplate can be

mounted in Class G3 harsh environments.

ENHANCED RELIABILITY (FAULTTOLERANCE)

The unique and patented fault-tolerant operation of

the FCP280 improves reliability relative to legacy

process controllers. The fault-tolerant version of the

FCP280 consists of two modules operating in

parallel, with two Ethernet connections to The Mesh

control network. The two FCP280 modules, married

together as a fault-tolerant pair, provide continuous

operation of the controller in the event of virtually any

hardware failure occurring within one module of the

pair.

Both modules receive and process information

simultaneously, and faults are detected by the

modules themselves. One of the significant methods

of fault detection is comparison of communication

messages at the module external interfaces.

Messages only leave the FCP280 when both

FCP280s agree on the message being sent (bit for

bit match). Upon detection of a fault, self-diagnostics

are run by both modules to determine which module

is defective. The non-defective module then assumes

control without affecting normal system operations.

This fault-tolerant solution has the following major

advantages over controllers that are merely

redundant:

No bad messages are sent to the field or to

applications using controller data because no

message is allowed out of the controller unless

both modules match bit for bit on the message

being sent.

The secondary controller is synchronized with the

primary one, which ensures up to the moment

data in the event of a primary controller failure.

The secondary controller will have latent flaws

detected prior to any switchover because it is

performing exactly the same operations as the

primary controller.

UPGRADE OPTIONS

Multiple options are available for replacing existing

control processors with the FCP280. A fault-tolerant

FCP280 may replace a fault-tolerant FCP270 or

ZCP270. It may import the CP database from the

CP270 it is replacing, for compatibility and minimal

configuration time.

As well the FCP280 provides an increase in

performance and block processing capacity over the

CP270s. When replacing FCP270s, the FCP280

eliminates the need for FEM100 hardware.

For ease of replacement, the fault-tolerant or nonfault-tolerant FCP280 in its baseplate has the same

dimensions as the fault-tolerant or non-fault-tolerant

FCP270 in its baseplate.

Cabling the 100 Series FBMs or Migration products

to an FCP280 baseplate consists of extending the

remote 268 Kbps fieldbus between enclosures. This

is accomplished using termination cable assemblies

(TCAs) and Fieldbus Isolators (FBIs) to provide

connections between primary and extended fieldbus

segments.

The optional FBI200 can extend the 2 Mbps HDLC

fieldbus between 200 Series FBMs from 60 m (198 ft)

up to 305 m (1000 ft). As well, it can extend the

268 Kbps HDLC fieldbus between 100 Series FBMs

from 60 m (198 ft) up to 1830 m (6000 ft).

As with earlier generations of control processors, up

to 64 100 Series FBMs (including expansion

modules) attach to Fieldbus ports through Fieldbus

Isolators. (Up to 24 100 Series FBMs, excluding

expansion modules, can connect to each isolator.

However, the expansion modules are considered

100 Series FBMs in this “64 100 Series FBMs”

maximum discussed in this PSS.)

Available upgrade scenarios are available in Field

Control Processor 280 (FCP280) User’s Guide

(B0700FW).

FBI200 FIELDBUS ISOLATOR/FILTER

The FBI200 Fieldbus Isolator/Filter extends the length

of the 268 Kbps module Fieldbus from the FCP280

to 100 Series FBMs and similar competitive migration

modules up to 1830 m (6000 ft) over a twinaxial

Fieldbus cable. See Figure 2 on page 4.

It can also extend the 2 Mbps HDLC fieldbus to

200 Series FBMs up to 305 m (1000 ft).

For more information on the FBI200, refer to FBI200

Fieldbus Isolator/Filter (PSS 21H-2Y18 B4).

FIRMWARE UPGRADES WHILE ON-LINE

For fault-tolerant FCP280 modules, on-line image

upgrade replaces the executable image (operating

system) of a running FCP280 with a newer image

without having to shut down the equipment being

controlled by the FCP280.

TIME SYNCHRONIZATION, SOE, TDR/TDA

The Foxboro Evo Process Automation System

supports time synchronization using either an

externally maintained optional source of Universal

Coordinated Time (UTC) from GPS satellites or an

internal source using proprietary software. FCP280s

that receive time updates via the external time source

synchronize their FBMs to 1 ms. For more

information on time synchronization, refer to Time

Synchronization Overview (PSS 21S-1C2 B3).

Time stamping is used for alarm messages, values

sent to the historian, and the Sequence Of Events

(SOE) and Transient Data Recorder (TDR), and

Transient Data Analyzer (TDA) features.

SOE data are discrete points that are time stamped at the FBM, optionally to 1 ms, and sent to the workstation on a change basis. TDR/TDA data are analog or digital points that are time stamped at the FBM and sent to the workstation every 10 ms. These features are supported by client software in the workstation. For information on this new software, refer to Field Control Processor 280 (FCP280) Integrated Control Software (PSS 31S-3B3 B3). SOFTWARE CONTROL FEATURES The FCP280 performs regulatory, logic, timing, and sequential control, as well as data acquisition, alarm detection, and alarm notification. Process variables are controlled using time-proven algorithms (mathematical computations performing specific functions). The algorithms are contained in functional control blocks, which on-site process engineers configure to implement the desired control strategies. The versatility of the algorithms, coupled with the variety of FBMs available, provides control capabilities suited to a broad range of process applications. Control strategies ranging from simple feedback and cascade loops to highly sophisticated feedforward, nonlinear, and complex characterization control schemes are readily implemented. The FCP280 also supports the following features: Setting and reading the FCP280 letterbug via the buttons on the faceplate Alarm enhancements to function blocks: re-alarming on changes to alarm priority, re-alarming based upon a configurable time delay deadband, and alarm suppression based upon time Optional UTC external time synchronization Improved controller performance Optional self-hosting mode allows the FCP280 to start up and run, executing its configured control scheme using the checkpoint file stored in flash memory. This allows the FCP280 to boot itself with a valid control database even if its host workstation is not present. Support for high speed capabilities such as ladder logic, Motor Driven Actuator Controller (MDACT), and Distributed Proportional Integral Derivative functionality (DPIDA) DEVICES SUPPORTED The FCP280 supports the following devices on the 2 Mbps fieldbus: All Compact and standard 200 Series FBMs (FBM201, FBM202, and so forth), which can support many types of intelligent field devices, including those on FOUNDATION fieldbus, PROFIBUS, HART, and DeviceNet networks Field Device Systems Integrator (FDSI) modules Intrinsically Safe I/O Subsystem (ISCM) – refer to PSS 21H-2Y6 B4). DCS Migration fieldbus Modules for Siemens APACS+ Systems DCS Migration fieldbus Modules for Westinghouse WDPF® Systems DCS Migration fieldbus Modules for Fisher’s PROVOX® Series 20 Migration with HART DCS Migration fieldbus Modules for Honeywell® TDC 2000 Systems with HART. The FCP280 supports the following devices on the 268 Kbps fieldbus: 100 Series FBMs (FBM01, FBM02, and so forth) SPECTRUM™ Migration Integrators SPEC 200™ Control Integrators SPEC 200 MICRO™ Control Integrators SPEC 200 CCM Control Integrators

Leave a comment

Your email address will not be published. Required fields are marked *