The Schneider Electric brand and any trademarks of Schneider Electric SE and its

subsidiaries referred to in this guide are the property of Schneider Electric SE or its

subsidiaries. All other brands may be trademarks of their respective owners.

This guide and its content are protected under applicable copyright laws and furnished

for informational use only. No part of this guide may be reproduced or transmitted in

any form or by any means (electronic, mechanical, photocopying, recording, or

otherwise), for any purpose, without the prior written permission of Schneider Electric.

Schneider Electric does not grant any right or license for commercial use of the guide

or its content, except for a non-exclusive and personal license to consult it on an “as is”

basis. Schneider Electric products and equipment should be installed, operated,

serviced, and maintained only by qualified personnel.

As standards, specifications, and designs change from time to time, information

contained in this guide may be subject to change without notice.

To the extent permitted by applicable law, no responsibility or liability is assumed by

Schneider Electric and its subsidiaries for any errors or omissions in the informational

content of this material or consequences arising out of or resulting from the use of the

information contained herein.

Features

Key features of the FBM232 are:

• 10 Mbps or 100 Mbps Ethernet network transmission rate to/from field device

• Communicates with up to 64 field devices

• I/O software driver is downloadable from a library of available protocols

• Up to 2000 DCI block connections

• Integrates field device data into a Foxboro DCS control database using Ethernet

connectivity

• Field mounted

• Class G3 (harsh) environments.

I/O Drivers

This fieldbus module (FBM) is a generic Ethernet hardware module in which different

software drivers can be loaded. These drivers configure the FBM to recognize a

particular protocol used by the device. Several of the software drivers are standard

product offerings. Other custom drivers can be developed to meet specific needs.

These drivers are dynamically downloaded to the FBM232 with software code

specifically designed to interface with the third party device’s protocol. The

configuration procedures and the software requirements for each driver are unique to

the device(s) being integrated into the system.

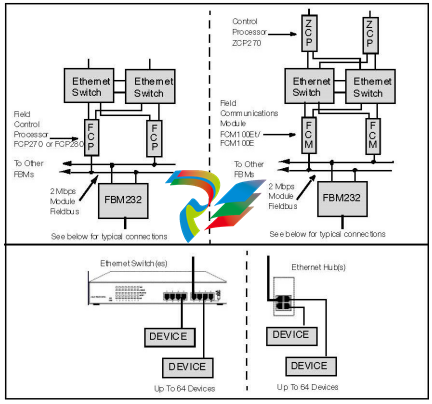

Figure 1. FBM232 in Typical Network Configuratio

Ethernet Link Setup

Data communication between the FBM232 and field devices are through the RJ-45

connector located on the front of the FBM232 module. The RJ-45 connector of the

FBM232 can be connected through hubs, or through Ethernet switches to the field

devices (refer to Ethernet Switches for Use with FBM232, page 12). Connection of

multiple devices to the FBM232 requires a hub or switch.

Configurator

The FDSI configurator sets up the FBM232 XML based port and device configuration

files. The port configurator allows for easy setup of the communication parameters for

each port (such as, Dynamic Host Configuration Protocol (DHCP), IP addresses). The

device configurator is not needed for all devices, but when needed it configures

device specific and point specific considerations (such as, scan rate, address of the

data to be transferred, and the amount of data to be transferred in one transaction).

Operations

The FBM232 can access up to 64 devices to read or write data. From the Foxboro

DCS control station to which the FBM232 is connected, up to 2000 Distributed Control

Interface (DCI) data connections can be made to read or write data. Supported data

types are determined by the particular driver loaded on the FBM232, which converts

the data to the DCI data types listed below:

• An analog input or output value (integer or IEEE single-precision floating point)

• A single digital input or output value

• Multiple (packed) digital input or output values (packed in groups of up to 32

digital points per connection).

Thus the FBM232 can access up to 2000 analog I/O values, or up to 64000 digital I/O

values, or a combination of digital and analog values up to the maximum capacity a

user allows within the sizing guidelines of the control processor. The frequency of

access to the FBM232 data by a control station can be as fast as 500 ms. The

performance depends on each device type and the layout of data in the device.

The FBM232 collects the required data from the devices, performs the necessary

conversions, and then stores the converted data in its database for incorporation into

the Foxboro DCS plant management functions and operator displays. Data may also

be written out to the individual devices from the Foxboro DCS system.

Fieldbus Communications

The Fieldbus Communications Module (FCM100Et or FCM100E) or the Field Control

Processor (FCP270 or FCP280) interface the redundant 2 Mbps module Fieldbus

used by the FBMs. The FBM232 accepts communication from either path of the

redundant 2 Mbps module Fieldbus – should one path fail or be switched at the system

level, the module continues communication over the active path.

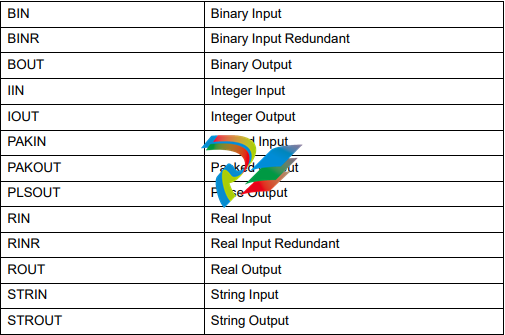

Control Block Support

The FBM232 offers control block support for the following standard Foxboro DCS

Distributed Control Interface (DCI) block types:

The DCI blocks are configured just like other Foxboro DCS control blocks. The DCI

blocks address and read/write data from/to the addressed field device.

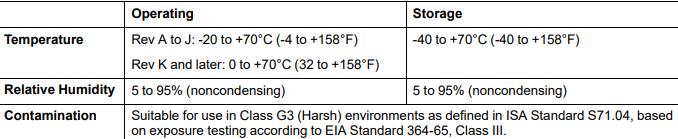

Standard, Rugged Design

The FBM232 has a rugged extruded aluminum exterior for physical and electrical

protection of the circuits. Enclosures, specially designed for mounting the FBMs,

provide various levels of environmental protection, up to Class G3 harsh

environments per ISA Standard S71.04.

Modular Baseplate Mounting

The module mounts on a Modular Baseplate, which accommodates up to four or eight

FBMs. The Modular Baseplate is either DIN rail mounted or rack mounted. The

Modular Baseplate includes signal connectors for the FBMs, provides connections for

independent dc power supplies, I/O cable connections, and 2 Mbps Module Fieldbus

connections.

Easy Removal/Replacement

The module can be removed or replaced without removing power.

Regulatory Compliance,

Product Safety

• Underwriters Laboratories (UL) for U.S. and Canada

UL/UL-C listed as suitable for use in UL/UL-C listed Class I, Groups A-D; Division

2; temperature code T4 enclosure based systems when connected to specified

Foxboro DCS processor modules as described in the Standard and Compact 200

Series Subsystem User’s Guide (B0400FA).

Communications circuits also meet the requirements for Class 2 as defined in

Article 725 of the National Electrical Code (NFPA No.70) and Section 16 of the

Canadian Electrical Code (CSA C22.1). Conditions for use are as specified in the

Standard and Compact 200 Series Subsystem User’s Guide (B0400FA).

• European Low Voltage Directive 2014/35/EU and Explosive Atmospheres (ATEX)

Directive 2014/34/EU

DEMKO certified as Ex nA IIC T4 for use in certified Zone 2 enclosure when

connected to specified processor modules as described in the Standard and

Compact 200 Series Subsystem User’s Guide (B0400FA).

• Marine Certification

ABS Type Approved and Bureau Veritas Marine certified for Environmental

Category EC31.

Calibration

Requirements

Calibration of the module is not required.

Environmental Specifications

Leave a comment

Your email address will not be published. Required fields are marked *