Product Overview

Providing users with powerful motor speed control in a compact, space saving design, the Allen-Bradley® PowerFlex® 4 and

40 AC drives are the smallest and most cost-effective members of the PowerFlex® family of drives. Available in power ratings

from 0.2 to 11 kW (0.25 to 15 HP) and in voltage classes of 120, 240, 480 and 600 volts, PowerFlex 4 and 40 are designed

to meet global OEM and end-user demands for flexibility, space savings, ease of use and are cost-effective alternatives for

speed control of applications such as machine tools, fans, pumps and conveyors and material handling systems

Packaging and Mounting

• Installation can be a virtual snap using the DIN rail mounting feature on

A and B frame drives. Panel mounting is also available, providing added

flexibility.

• Flange mount drives are available to reduce overall enclosure size.

• Zero Stacking™ is allowable for ambient temperatures up to 40 °C, saving

valuable panel space. 50 °C ambient temperatures are permitted with

minimal spacing between drives.

• Integral filtering is available on all 230V single phase ratings, providing a

cost-effective means of meeting EN55011, Class A and B EMC

requirements. External filters provide compliance to Class A and B

requirements for all PowerFlex 4 and 40 ratings.

• An optional IP30, NEMA/UL Type 1 conduit box is easily adapted to

the standard IP20 (NEMA Type Open) product, providing increased

environmental ratings.

• IP66, NEMA/UL Type 4X/12 (Indoor) for mounting directly in the

product environment. Listed by UL to resist dust, dirt, etc. and survive

high pressure water spray. Also certified by NSF to ensure conformity

with international food equipment standards.

Start Up, Programming and Operation

• An integral keypad provides out of the box operation using the local

potentiometer and control keys.

• The 10 most common application parameters are contained in the Basic

Program Group, making programming fast and easy.

• The programming keys have the same function as all other PowerFlex

drives, so if you can program one PowerFlex drive, you can program them

all.

• 4 digit display with 10 additional LED indicators provides an intuitive

display of drive status and information.

• Integral RS-485 communications can be used for programming from a

PC. It can also be used in a multi-drop network configuration. A serial

converter module provides connectivity to any controller with a DF1

port.

• A NEMA/UL Type 4X remote and NEMA/UL Type 1 hand-held

LCD keypad provide additional programming and control flexibility,

both featuring the popular CopyCat function

Optimized Performance

• Removable MOV to ground provides trouble-free operation when used on ungrounded

distribution systems.

• A relay pre-charge limits inrush current.

• Integral brake transistor, available on all ratings (except no brake version), provides

dynamic braking capability with simple low cost brake resistors.

• DIP switch settable 24V DC sink or source control for control wiring flexibility.

• 150% overload for 60 seconds or 200% overload for 3 seconds provides robust overload

protection.

• Adjustable PWM frequency up to 16 kHz ensures quiet operation.

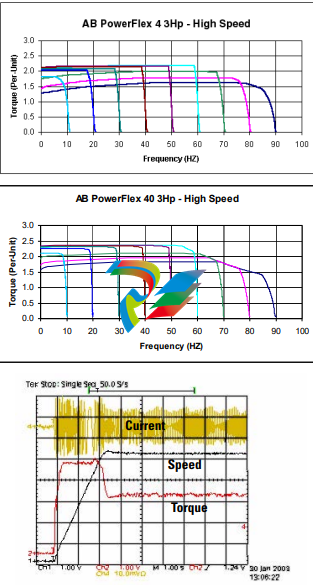

Sensorless Vector Performance

PowerFlex 4

• Drive automatically provides auto boost (IR

compensation) and slip compensation.

• Provides excellent speed regulation and high levels of

torque across the entire speed range of the drive, and

improved speed regulation even as loading increases.

Sensorless Vector Control

PowerFlex 40

• Sensorless Vector Control provides exceptional speed

regulation and very high levels of torque across the

entire speed range of the drive.

• The Autotune feature allows the PowerFlex 40 to adapt

to individual motor characteristics.

Performance

• This graph depicts the ability of a PowerFlex 40 drive to

accelerate into at least 150% load. A PowerFlex 4 will

perform similarly, but with a slightly higher acceleration

time.

• At 100% motor load, the drive will run the motor at

synchronous speed.

• Excellent current regulation.

• Linear acceleration.

• Best in class digital input response time and

repeatability

Performance

• Sensorless Vector Control develops high torque over a wide speed range

and adapts to individual motor characteristics.

• Variable PWM allows the drive to output more current at low

frequencies.

• Integral PID functionality enhances application flexibility.

• Timer, Counter, Basic Logic and StepLogic™ functions can reduce

hardware design costs and simplify control schemes.

– Timer function: Relay or opto outputs controlled by drive

performing timer function. Timer is initiated by activating a digital

input programmed as “Timer Start.”

– Counter function: Relay or opto outputs controlled by drive

performing counter function. Counter function is activated by a

digital input programmed as “Counter Input.”

– Basic Logic: Relay or opto outputs controlled by status of digital

inputs programmed as “Logic Inputs.” Performs basic Boolean logic.

– StepLogic: Logic-based steps using preset speed settings. Each step

can be programmed for a specific speed, direction and accel/decel

profile. Drive outputs can be used to indicate which step is being performed.

I/O

• Two (2) Analog Inputs (one unipolar and one bipolar) are

independently isolated from the rest of the drive I/O. These inputs

can be toggled between via a digital input.

• Three (3) fixed and four (4) fully programmable Digital Inputs

provide application versatility.

• One (1) Analog Output is DIP switch selectable for either

0…10V or 0…20mA. This scalable, 10-bit output is suitable for

metering or as a speed reference for another drive.

• Two (2) Opto Outputs and one (1) form C relay output can be

used to indicate various drive, motor or logic conditions.

Communications

• Integral communication cards such as DeviceNet™, EtherNet/IP™,

PROFIBUS™ DP, LonWorks® and, ControlNet™ can improve machine

performance.

• The DSI Wireless Interface Module (WIM) provides a wireless

communication interface between a Pocket PC, laptop computer or

desktop computer equipped with Bluetooth® wireless technology, and any

Allen-Bradley® product supporting the DSI™ protocol.

• Field installed option allows for future addition of stand-alone drives to a

network.

• Online EDS file creation with RS NetWorx™ providing ease of set-up on a

network.

Versatile Programming and Network Solutions

• PowerFlex 4 and PowerFlex 40 are compatible with

any device that acts as a RTU Master and supports

standard 03 and 06 RTU commands.

• A network can be configured using PowerFlex 40

drives with optional communication cards for high

performance and flexible configuration capabilities.

– BACnet

– ControlNet

– DeviceNet

– EtherNet/IP

– LonWorks

– PROFIBUS DP

• A multi-drive solution can be reached using a single

PowerFlex 40 DeviceNet option, with the ability for

up to five drives to reside on one node.

• Integral RS485 communications enable the drives to

be used in a multi-drop network configuration. A

serial converter module (SCM) provides connectivity

to any controller with a DF1 port. The SCM can be

eliminated if the controller acts as a RTU Master.

PC Programming Software

Through the use of a Serial Converter Module and

DriveExplorer™ or DriveTools™ SP software,

programming can be greatly simplified.

DriveExplorer Software

• View and modify drive and adapter parameters in

a method similar to the file management capability

of Microsoft Windows Explorer.

• Operate the drive via an on-screen Control Bar,

which is a tool that allows you to start, stop, and

change the speed reference of the drive.

• Save, restore and print parameter information.

• Compare current parameters with factory defaults

or previously saved parameter values.

• Edit, upload and download parameters.

DriveTools SP Software

• Online and offline programming capability

• In-grid and dialog-based parameter editing

• Immediate visual indication of drive and communication status when viewing online drive

• Integrated HTML Help architecture

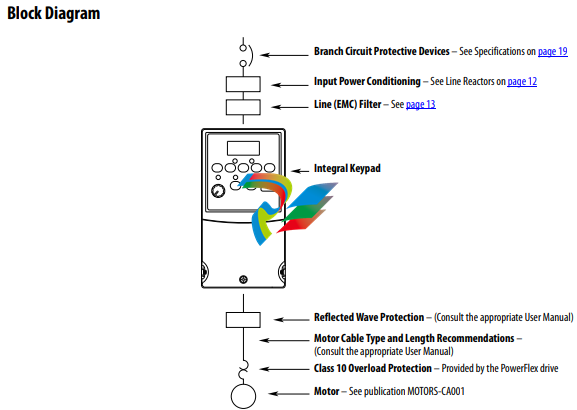

Installation Considerations

PowerFlex 4 and 40 drives have the following built in protective features to help simplify installation.

• Ground fault protection while starting and running ensures reliable operation

• Electronic motor overload protection increases motor life

• Removable MOV to ground ensures compatibility with ungrounded systems

• 6kV transient protection provides increased robustness for 380…480V system voltages

There are many other factors that must be considered for optimal performance in any given application. The block diagram

below highlights the primary installation considerations. Consult the PowerFlex 4 or PowerFlex 40 User Manual,

Publications 22A-UM001 or 22B-UM001 available online at www.rockwellautomation.com/literature, for detailed

recommendations on input power conditioning, CE conformance (EMC filtering), dynamic braking, reflected wave

protection, motor cable types and motor cable distances.

Control Wiring

PowerFlex 4

• The control logic is 24V DC and can be set for either

Sink or Source control via a DIP switch setting.

• Control terminal screws are sized for a conventional

blade screw driver.

• I/O Terminals 1, 2 and 3 are dedicated for Stop, Start

and Reverse operation respectively. These I/O

Terminals can be programmed for 2- or 3-Wire

operation to meet application requirements.

• I/O Terminals 4 and 5 are programmable and provide

added flexibility. Programmable functions include:

– Local Control

– Preset Frequencies

– Jog

– RS485 Control

– Second Accel/Decel

– Auxiliary Fault

– Clear Fault

• Speed can be controlled via a 0…10V input or 4…20

mA input. Both are electrically isolated from the drive.

• One form C relay can be programmed to provide the

status of a wide variety of drive conditions.

• The drive is shipped with a jumper installed between

I/O Terminals 01 and 11 to allow out of box operation

from the keypad.

PowerFlex 40

• The control logic is 24V DC and can be set for either

Sink or Source control via a DIP switch setting.

• Control terminal screws are sized for a conventional

blade screw driver.

• I/O Terminals 1, 2 and 3 are dedicated for Stop, Start and

Reverse operation respectively. These I/O Terminals can

be programmed for 2- or 3-Wire operation to meet

application requirements.

• I/O Terminals 5, 6, 7 and 8 are programmable and

provide added flexibility. Programmable functions

include Local Control, Jog, Second Accel/Decel, Clear

Fault, Preset Frequencies, RS485 Control and Auxiliary

Fault.

• Speed can be controlled via a 0…10V input and/or 4…20

mA input. Both inputs are independently isolated from

the rest of the drive and can be used for applications such

as PID. Voltage input can be programmed for bipolar

operation.

• The drive is shipped with a jumper installed between I/O

Terminals 01 and 11 to allow out of box operation from

the keypad.

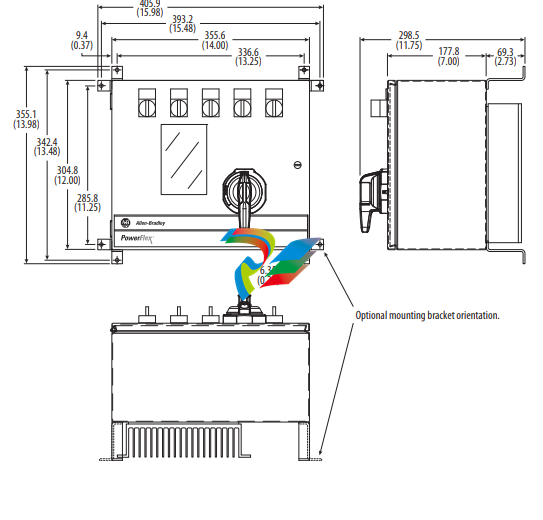

Enclosure Options and Approximate Dimensions

Leave a comment

Your email address will not be published. Required fields are marked *