Product Overview

The PowerFlex® 700 AC drive offers outstanding performance in an easy-to-use drive that you have come to

expect from Rockwell Automation. The PowerFlex 700 AC drive is designed to control three-phase induction

motors in applications with requirements ranging from the simplest speed control to the most demanding

torque control. The drive has volts per hertz, sensorless vector, and vector control. Vector control includes

Allen-Bradley’s patented Force Technology, which provides world class motor control.

Flexible Packaging and Mounting

• IP20, NEMA / UL Type 1 – For conventional mounting inside or outside a control cabinet. Conduit plate is removable for easy

installation and replacement without disturbing conduit.

• IP54, NEMA / UL Type 12 – standalone, wall mount drives are available for dust-tight applications with power ratings 75…200 Hp

(Frames 5 and 6).

• IP54, NEMA / UL Type 12 – Flange mount drives with an IP00, NEMA / UL Type Open front. These can be installed in a user supplied

cabinet to meet IP54, NEMA / UL Type 12. This allows most heat to be exhausted out the back of the cabinet while keeping the cabinet

protected. Power ratings range 75…200 Hp (Frames 5…6).

• Zero-Stacking™ Drive– Frame 0…6 drives can be mounted next to each other with no reduction of surrounding air temperature rating 50 °C (122 °F). This unique bookshelf design also allows access to one drive without disturbing another.

• Conformal Coating – The drive is coated in an insulator, or non-conducting substance, that helps protect it from moisture, fungus,

dust, corrosion, abrasion, and other environmental stresses caused by highly polluted atmospheres. The coating improves product

lifetime expectancy when exposure to corrosive environment is present. It helps maintain long-term surface insulation resistance,

ensuring operational integrity of the assembly.

Space Saving Hardware Features

• Integral EMC Filtering plus built-in DC bus choke common mode cores and common mode capacitors provides a compact, all-in-one

package solution for meeting EMC requirements. Frames 0…6 only.

• Internal Communications allows you to integrate the drive into the manufacturing process. Status indicators for all internal

communication options are visible on the cover for easy setup and monitoring of drive communications. You can easily manage

information from shop floor to top floor and seamlessly integrate their complete system as they control, configure, and collect data.

• Integral Dynamic Brake Transistor delivers a cost-effective means of switching regenerative energy without costly external

chopper circuits. These internal transistors are available in power ratings 0.5…200 Hp.

• Internal Dynamic Brake Resistor (up to 25 Hp) requires no extra panel space, and supplies a large amount of braking torque for

short periods.

Easy to Use Human Interface Tools

The PowerFlex 7-Class AC drives provide common Human Interface tools that are familiar and easy to use. These include the LCD Human

Interface modules and PC-based configuration tools.

Human Interface Module

The LCD Human Interface modules provide:

• Large and easy to read 7 line x 21 character backlit display

• Variety of languages (English, French, German, Italian, Spanish, Portuguese, Dutch)

• Alternate function keys for shortcuts to common tasks

• “Calculator-like” number pad for fast and easy data entry (Full Numeric version only)

• Control keys for local start, stop, speed, and direction

• Remote versions for panel mount application

Connected Components Workbench Software

Connected Components Workbench™ programming and configuration software leverage proven Rockwell Automation and Microsoft® Visual

Studio® technologies for fast and easy drive configuration, controller programming, and integration with the HMI editor.

The workbench includes:

• an intuitive interface and startup wizards

• localized language support

• online and offline configuration

• context-sensitive help

• supports PowerFlex drives, Micro800™ programmable controllers, and PanelView™ component graphic terminals

Outstanding Control and Performance

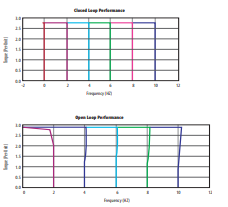

Multiple motor control algorithms allow performance that is matched to the application need:

• Volts/Hertz for simple Fan and Pump applications.

• Sensorless Vector for high torque production over a wide speed range.

• Vector for outstanding torque regulation and excellent low speed/zero speed

performance (w/Vector Control cassette).

The PowerFlex 700 drive’s Vector Control uses Allen-Bradley’s patented Force Technology

which provides excellent low-speed performance – whether it is operated with or without

feedback. While this industry-leading control provides the highest level of drive performance,

it is as easy to use as any general-purpose drive available.

Drives Features

• Fast-acting Current Limit and Bus Voltage Regulation result in maximum accel/decel without tripping.

• High-speed analog inputs improve drive response to torque or speed commands.

• Programming flexibility allows parameters to be linked within the drive.

• Flying Start delivers smooth and instantaneous connection into rotating loads, regardless of commanded direction, without the need

for any speed feedback.

• Integral Process PI Control can eliminate the need for a separate process loop controller.

• Inertia Ride-Through offers tripless operation during a prolonged power outage by using the rotating energy that is stored in high

inertia, low-friction loads.

• Position Indexer/Speed Profiler uses a 16-step indexer to provide point-to-point positioning or velocity profiling based on encoder

counts, digital inputs, parameter levels, or time.

• TorqProve™ assures control of the load when transferring control between the drive and a mechanical brake.

• Speed Regulation – Open Loop or Closed Loop

– Slip Compensation delivers a minimum 0.5% speed regulation without feedback hardware.

– Droop allows drives to load share without fighting each other.

– Encoder Feedback provides up to 0.001% speed regulation for the tightest application requirements.

• Torque Regulation – Open Loop or Closed Loop

– Open Loop torque regulation provides 5% regulation.

– Encoder Feedback provides 2% regulation and the ability to hold full load at zero speed.

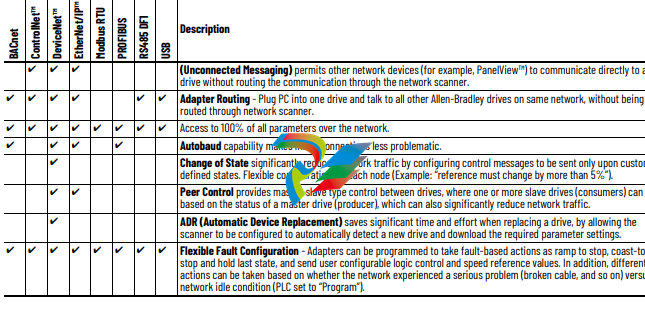

Unsurpassed Capability in Network Communications

PowerFlex drives are fully compatible with the wide variety of Allen-Bradley DPI™ communication adapters, offering the following benefits:

Drive, Fuse, and Circuit Breaker Ratings

The PowerFlex 700 can be installed with input fuses or an input circuit breaker. National and local industrial safety regulations and/or

electrical codes can determine additional requirements for these installations.

The tables on the following pages provide recommended AC line input fuse and circuit breaker information. See Fusing and Circuit Breakers

below for UL and IEC requirements. Sizes that are listed are the recommended sizes based on 40 °C (104 °F) and the U.S. NEC. Other country,

state, or local codes can require different ratings. Tables with DC link fuse recommendations for DC input drives are also provided.

Fusing

The recommended fuse types are listed below. If available current ratings do not match those listed in the tables that are provided, choose

the next higher fuse rating.

• IEC – BS88 (British Standard) Parts 1 and 2, EN60269-1, Parts 1 and 2(1), type gG or equivalent must be used.

• UL – UL Class CC, T, RK1, or J must be used for Frames 0…6.

Circuit Breakers

The “non-fuse” listings in the following tables include inverse time circuit breakers, instantaneous trip circuit breakers (motor circuit

protectors) and 140M Motor Protection Circuit Breakers (MPCBs) that are rated for use as self-protected combination motor controller

(Frames 0…6 only). If one of these is chosen as the desired protection method, the following requirements apply:

• IEC – Both types of circuit breakers and 140M self-protected combination motor controllers (Frames 0…6 only) are acceptable for IEC

installations.

• UL – Only inverse time circuit breakers and the specified 140M self-protected combination motor controllers (Frames 0…6 only) are

acceptable for UL installations.

Circuit Breaker – inverse time breaker. For US NEC, minimum size is 125% of motor FLA. Ratings that are shown are maximum.

(5) Motor Circuit Protector – instantaneous trip circuit breaker. For US NEC, minimum size is 125% of motor FLA. Ratings that are shown are maximum.

(6) Bulletin 140M devices with adjustable current range must have the current trip set to the minimum range that the device does not trip.

(7) Manual Self-Protected (Type E) Combination Motor Controller, UL Listed for 208V Wye or Delta, 240V Wye or Delta, 480Y/277V or 600Y/347V. Not UL Listed for use on 480V or 600V Delta/

Delta, corner ground, or high-resistance ground systems.

(8) The A1C ratings of the Bulletin 140M devices can vary. See publication 140-TD005 or 140M-TD002.

(9) Maximum allowable rating by US NEC. Exact size must be chosen for each installation.

(10) UL Type 12/IP54 (flange mount) heat sink ambient temperature rating is 40° C/ambient of unprotected drive portion (inside enclosure) is 55° C. The ambient temperature for the UL Type 12/

IP54 standalone drives is 40° C.

(11) Must remove top label and vent plate, drive enclosure rating is IP00, NEMA / UL Type Open.

(12) Frames 0…4 temperature rating is for NEMA / UL Type Open. The adhesive top label must be removed to operate drive at this temperature. Frames 5 and 6 do not have a top label.

(13) Drives have dual current ratings; one for normal duty applications, and one for heavy-duty applications. The drive can be operated at either rating.

(14) Note: 600V class drives below 77 amps (Frames 0…4) are declared to meet the Low Voltage Directive and UK Low Voltage Regulations. It is the responsibility of the user to determine

compliance to the EMC Directive and UK EMC Regulations.

(15) When using a Manual Self-Protected (Type E) Combination Motor Controller, the drive must be installed in a ventilated or non-ventilated enclosure with the minimum volume that is specified

in this column. Application-specific thermal considerations can require a larger enclosure.

(16) Temperature rating is for IP20, NEMA / UL Type 1. For IP00, NEMA Type Open the temperature rating is 65 °C for the control board and 40 °C for the heat sink entry air.

(17) 40 °C = 104 °F; 45 °C = 113 °F; 50 °C = 122 °F; 55 °C = 131 °F

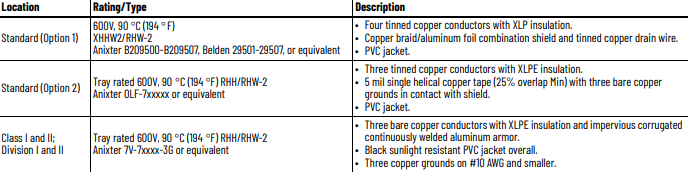

Cable Recommendations

Power Cable Types Acceptable for 200…600 Volt Installations

Various cable types are acceptable for drive installations. For many installations, unshielded cable is adequate, provided it can be separated

from sensitive circuits. As an approximate guide, allow a spacing of 0.3 meters (1 foot) for every 10 meters (32.8 feet) of length. In all cases,

long parallel runs must be avoided. Do not use cable with an insulation thickness less than or equal to 15 mils (0.4mm/0.015 in.). Use Copper

wire only. Wire gauge requirements and recommendations are based on 75 °C (167 °F). Do not reduce wire gauge when using higher

temperature wire. See table below.

Unshielded

THHN, THWN or similar wire is acceptable for drive installation in dry environments provided adequate free air space and/or conduit fill rates

limits are provided. Do not use THHN or similarly coated wire in wet areas. Any wire that is chosen must have a minimum insulation

thickness of 15 mils and should not have large variations in insulation concentricity.

Shielded/Armored Cable

Shielded cable contains all general benefits of multi-conductor cable with the added benefit of a copper braided shield that can contain

much of the noise that is generated by a typical AC drive. Strong consideration for shielded cable should be given in installations with

sensitive equipment such as weigh scales, capacitive proximity switches and other devices that may be affected by electrical noise in the

distribution system. Applications with large numbers of drives in a similar location, imposed EMC regulations or a high degree of

communications/ networking are also good candidates for shielded cable.

Shielded cable may also help reduce shaft voltage and induced bearing currents for some applications. In addition, the increased impedance

of shielded cable may help extend the distance that the motor can be located from the drive without the addition of motor protective devices

such as terminator networks.

Consideration should be given to all general specifications that are dictated by the environment of the installation, including temperature,

flexibility, moisture characteristics and chemical resistance. In addition, a braided shield should be included and be specified by the cable

manufacturer as having coverage of at least 75%. An additional foil shield can greatly improve noise containment.

A good example of recommended cable is Belden 295xx (xx determines gauge). This cable has four (4) XLPE insulated conductors with a

100% coverage foil and an 85% coverage copper braided shield (with drain wire) surrounded by a PVC jacket.

Other types of shielded cable are available, but the selection of these types may limit the allowable cable length. Particularly, some of the

newer cables twist four conductors of THHN wire and wrap them tightly with a foil shield. This construction can greatly increase the cable

charging current required and reduce the overall drive performance. Unless specified in the individual distance tables as tested with the

drive, these cables are not recommended and their performance against the lead length limits supplied is not known.

Maximum Motor Cable Lengths

For information on maximum motor cable lengths, see the Wiring and Grounding Guidelines for Pulse Width Modulated (PWM) AC Drives,

publication DRIVES-IN001.

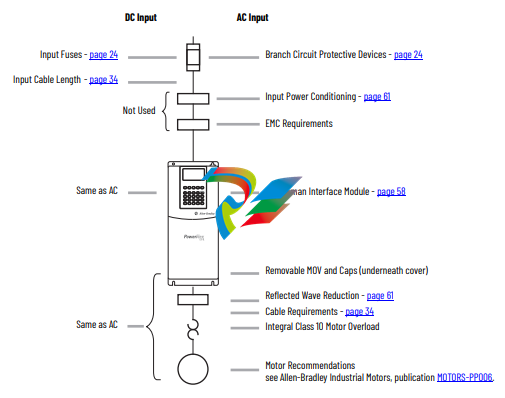

Power Wiring

The PowerFlex 700 has the following built in protective features to help simplify installation:

• Ground fault protection during startup and running ensures reliable operation

• Electronic motor overload protection increases motor life

• Removable MOV to ground and common mode capacitors to ground ensure compatibility with ungrounded systems. These devices

must be disconnected if the drive is installed on a resistive grounded distribution system, an ungrounded distribution system, a B

phase grounded distribution system or impedance grounded system. These devices must also be disconnected if the drive power

source is a regenerative unit (such as a bus supply and brake) or is DC fed from an active converter.

• 6 kV transient protection provides increased robustness for 380…480V system voltages

There are many other factors that must be considered for optimal performance in any given application. The block diagram below highlights

the primary installation considerations. Consult the Wiring and Grounding Guidelines for Pulse Width Modulated (PWM) AC Drives, publication

DRIVES-IN001 for detailed recommendations on input power conditioning, dynamic braking, reflected wave protection and motor cable

types.

Leave a comment

Your email address will not be published. Required fields are marked *