ABB SDCS-CON-4 Digital inputs is a kind of digital inpt module produced by ABB Company, mainly used in industrial automation control systems. The following are some advantages of this product: High reliability: ABB’s products are renowned for their high quality and reliability, and SDCS-CON-4 Digital inputs is no exception. It can operate stably in various industrial environments. Flexible configuration: This module supports multiple digital input signal types, such as NPN, PNP, etc., and can be flexibly configured according to actual application requirements. Fast response time: It features a relatively fast signal response time, capable of promptly capturing and processing changes in input signals, meeting the requirements of real-time control. High precision: It can accurately detect and convert digital signals, ensuring the accuracy and stability of the control system. Easy to install and maintain: The module is compactly designed and easy to install. Meanwhile, ABB offers abundant technical support and documentation, making maintenance and troubleshooting relatively simple. Isolation protection: It usually has a signal isolation function, which can effectively prevent the influence of external interference on the system and improve the safety and reliability of the system. Strong compatibility: It has good compatibility with ABB’s other automation products and various control systems, facilitating system integration and expansion. Diagnostic function: It has certain diagnostic functions and can display the working status of the module through indicator lights or other means, helping users quickly locate problems. Anti-interference ability: It can still maintain stable performance in industrial environments with strong electromagnetic interference. Modular design: The modular design makes replacement and upgrade very convenient, reducing downtime. These advantages have enabled ABB SDCS-CON-4 Digital inputs to be widely applied in the field of industrial automation

Brand: ABB Model: SDCS-CON-4 Rated Voltage: 400V Power: 800kW Product Certification: 3C Dimensions: 450, 350, 120mm Weight: 50kg Structure Form: Modular Installation Method: Control Room Installation LD Instruction Processor: Soft PLC Processing Customization It is these parameters that indicate that SDCS-CON-4 is a modular digital input device, suitable for control room installation, and supports soft PLC programming. It has specific dimensions and weights and has p

assed the 3C product certification. When purchasing or using this device, these parameters are crucial for understanding its performance and application environment. In addition, the SDCS-CON-4 module is produced by ABB and sold through multiple suppliers, such as Beijing Xinhe New Technology Development Co., Ltd. and Xiamen Amicon Technology Co., LTD. These suppliers offer technical support and services and guarantee the quality of the products

Recommend

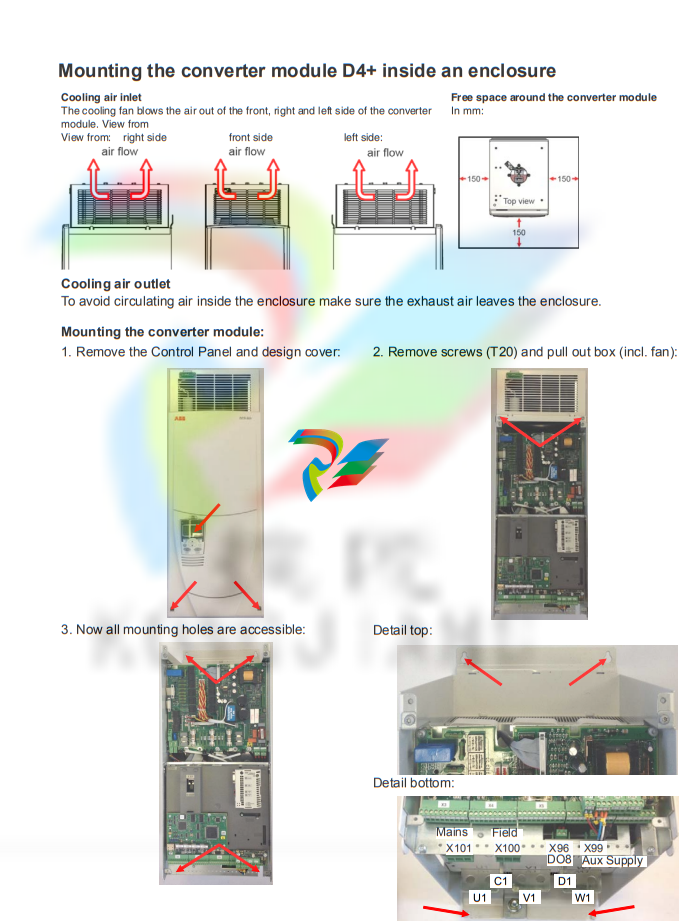

ed air entry / exit sizes in case of filters (IP22)

Size Nominal converter current [A] Air entry size [m2] Air exit size [m2] D1 20 to 140 0.22 0.11 D2 180 to 260 D3 315 to 350 D3 405 to 520 0.31 0.15 D4 610 to 1000 D4+ 1190 0.22 0.11 D5 900 to 2000 D6 1900 to 3000 0.44 0.31 D7 2050 to 5200 0.52

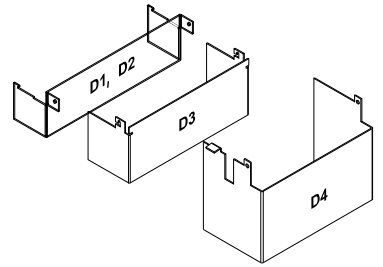

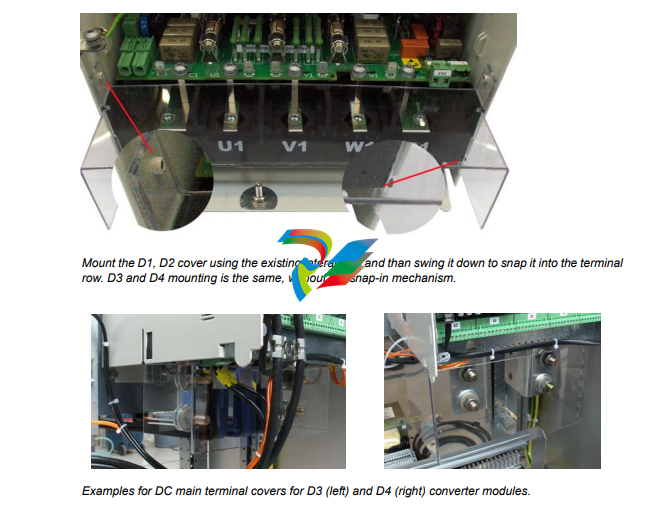

Terminal options for converter modules size D1 – D4 There are different options to protect and connect the terminals of converter modules size D1 – D4. Connection of D4 converter module DC terminals In some cases it is beneficial to use lug bars for easy DC cable connection

What this chapter contains

This chapter contains the safety instructions which you must follow when installing,

operating and servicing the drive. If ignored, physical injury or death may follow, or

damage may occur to the drive, the motor or driven equipment. Read the safety

instructions before you work on the unit.

To which products this chapter applies

The information is valid for the whole range of the product DCS800, the converter

modules DCS800-S0x size D1 to D7, field exciter units DCF80x, etc. like the Rebuild

Kit DCS800-R00-9xxx.

Use of warnings and notes

There are two types of safety instructions throughout this manual: warnings and

notes. Warnings caution you about conditions which can result in serious injury or

death and/or damage to the equipment. They also tell you how to avoid the danger.

Notes draw attention to a particular condition or fact, or give information on a

subject. The warning symbols are used as follows:

Dangerous voltage warning warns of high voltage which can cause

physical injury and/or damage to the equipment.

General danger warning warns about conditions, other than those

caused by electricity, which can result in physical injury or death and/or

damage to the equipment.

Electrostatic sensitive discharge warning warns of electrostatic

discharge which can damage the equipment.

Safety instructions

5

3ADW000194R0811 DCS800 Hardware Manual us h

Installation and maintenance work

These warnings are intended for all who work on the drive, motor cable or motor.

Ignoring the instructions can cause physical injury or death and/or damage to the

equipment..

WARNING!

• Only qualified electricians are allowed to install and maintain the drive!

• Never work on the drive, motor cable or motor when main power is applied.

Always ensure by measuring with a multimeter (impedance at least 1 Mohm)

that:

1. Voltage between drive input phases U1, V1 and W1 and the frame is

close to 0 V.

2. Voltage between terminals C+ and D- and the frame is close to 0 V.

• Do not work on the control cables when power is applied to the drive or to the

external control circuits. Externally supplied control circuits may cause

dangerous voltages inside the drive even when the main power on the drive is

switched off.

• Do not make any insulation resistance or voltage withstand tests on the drive or

drive modules.

• Isolate the motor cables from the drive when testing the insulation resistance or

voltage withstand of the cables or the motor.

• When reconnecting the motor cable, always check that the C+ and D- cables

are connected with the proper terminal.

Note:

• The motor cable terminals on the drive are at a dangerously high voltage when

the main power is on, regardless of whether the motor is running or not.

• Depending on the external wiring, dangerous voltages (115 V, 220 V or 230 V)

may be present on the relay outputs of the drive system (e.g. SDCS-IOB-2 and

RDIO).

• DCS800 with enclosure extension: Before working on the drive, isolate the

whole drive from the supply

Terminal cover according to VBG 4 regulations

For converter modules size D1 – D4 shrouds for protection against contact are

provided.

Id No. Id No. | Id No. |

| 3ADT631137P0001 | D1, D2 |

| 3ADV400208P0001 | D3 |

| 3ADV400207P0001 | D4 |

Chapter overview

This chapter contains the instructions that must be followed when selecting the

motor, cables, protections, cable routing and way of operation for the drive system.

Always follow local regulations. This chapter applies to all DCS800 converter

modules.

Attention:

If the recommendations given by ABB are not followed, the drive may experience

problems that the warranty does not cover. See also Technical Guide.

Options

Line reactors (L1)

For armature and field supply.

When thyristor converters operate, the line voltage is short-circuited during

commutation from one thyristor to the next. This operation causes voltage dips in the

mains PCC (point of common coupling). For the connection of a power converter

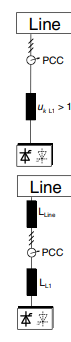

system to the mains, one of the following configurations applies:

Configuration A

When using a converter, a minimum of impedance is required to

ensure proper performance of the snubber circuit. Use a line reactor

to meet this minimum impedance requirement. The value must

therefore not drop below 1 % uk (relative impedance voltage). It

should not exceed 10 % uk, due to considerable voltage drops at the

converters outputs.

Configuration B

If special requirements have to be met at the PCC (standards like EN

61 800-3, DC and AC drives at the same line, etc), different criteria

must be applied for selecting a line reactor. These requirements are

often defined as a voltage dip in percent of the nominal supply

voltage. The combined impedance of ZLine and ZL1 constitute the total

series impedance of the installation. The ratio between the line

impedance and the line reactor impedance determines the voltage dip

at the PCC. In such cases, line chokes with an impedance around 4 %

are often used.

Example calculation with ukLine = 1 % and ukL1 = 4 %:

Voltage dip = ZLine / (ZLine + ZL1) = 20 %. Detailed calculations see

Technical Guide.

Start, Stop and E-Stop control The relay logic is splitted into four parts: 1: Generation of the On / Off and Start / Stop command: The commands represented by K20 and K21 (latching interface relay) can also be generated by a PLC and transferred to the terminals of the converter either by relays, using galvanic isolation or directly via 24 V signals. There is no need to use hardwired signals. Transfer these commands via serial communication. Even a mixed solution can be realized by selecting different possibilities for the one or the other signal (see parameter group 11). 2: Generation of control and monitoring signals: Control the main contactor K1 for the armature circuit by the dry contact of DO8 located on the SDCS-PIN-4 or SDCS-POW-4. The status of motor (K6) and converter (K8) fans can be monitored by means of MotFanAck (10.06) and ConvFanAck (10.20). 3: Off2 (Coast Stop) and Off3 (E-stop): Beside On / Off and Start / Stop the drive is equipped with two additional stop functions Off2 (Coast Stop) and Off3 (E-stop) according to Profibus standard. Off3 (E-stop) is scalable via E StopMode (21.04) to perform stop category 1. Connect this function to the E-stop push button without any time delay. In case of E StopMode (21.04) = RampStop the K15 timer relay must be set longer than E StopRamp (22.04). For E StopMode (21.04) = Coast the drive opens the main contactor immediately. Off2 (Coast Stop) switches the DC current off as fast as possible and prepares the drive to open the main contactor or drop the mains supply. For a normal DC motor load the time to force the DC current to zero is below 20 ms. This function should be connected to all signals and safety functions opening the main contactor. This function is important for 4-Q drives. Do not open main contactor during regenerative current. The correct sequence is: 1. switch off regenerative current 2. then open the main contactor In case the E-stop push button is hit, the information is transferred to the converter via DI5. In case E StopMode (21.04) = RampStop or TorqueLimit the converter will decelerate the motor and then open the main contactor. If the drive has not finished the function within the K15 timer setting, the drive must get the command to switch off the current via K16. After the K16 timer has elapsed, the main contactor is opened immediately, independent of the drive’s status.

ABB is a global technology leader in electrical and automation fields, formed in 1988 through the merger of Sweden’s ASEA and Switzerland’s BBC Brown Boveri, with its headquarters located in Zurich, Switzerland. The company operates in over 100 countries and regions worldwide, employing approximately 105,000 people.

**Business Segments**

– **Electrical Products**: Provides transformers, switchgear, circuit breakers, etc., widely used in power, industrial, and other sectors.

– **Automation Solutions**: Delivers automation systems for industries such as manufacturing and transportation to enhance production efficiency.

– **Robotics and Discrete Automation**: Develops industrial robots and automation equipment for sectors like automotive and electronics.

– **Motion Control**: Manufactures motors, variable frequency drives, etc., enabling precise motion control to improve equipment performance.

**Development in China**

– 1907: ABB supplied China’s first steam boiler, marking the beginning of its collaboration with China.

– 1974: Established its China Business Department in Hong Kong; 1979: Set up an office in Beijing.

– 1994: Relocated its China headquarters to Beijing; 1995: Founded ABB (China) Limited.

– Currently operates 27 local enterprises in China, employing 15,000 staff, with business presence in over 130 cities.

**Key Achievements**

– Invented the world’s first three-phase power transmission system and the first self-cooled transformer, pioneering their commercial applications.

– Products and technologies are widely used in major domestic and international projects, such as the Great Hall of the People in Beijing and the Three Gorges Project.

**Sustainability and Social Responsibility**

– Committed to driving sustainability by leveraging technological innovation to help customers reduce environmental impact.

– Actively fulfills social responsibilities and is widely recognized as an employer of choice.

**Future Outlook**

ABB will continue to be innovation-driven, advancing the integration of electrification, automation, and digitalization technologies to support global industrial transformation and contribute to a more sustainable and efficient future.

*Content generated by AI model, for reference only.*

*Save to favorites*

Leave a comment

Your email address will not be published. Required fields are marked *