Safety Summary (continued)

• Process technicians are to be present when testing and operating process

objects.

• Never activate any System Initialization push-button if any uncertainty

exists regarding exactly what occurs within the system during initialization.

ALWAYS CHECK FIRST.

• Remember at all times, that the control system can be controlled from a

remote engineering station, connected at another node via Control

Network.

• Remember, the AC 800M Controller will start automatically when voltage

is applied.

Taking steps to bring the process to a safe state, provides an improved level of

safety when power supplies, communication links or parts of the control system

fail. Such steps may require, for example, the installation of valves or relays that

automatically return to a fail-safe position.

Product Safety

The following safety rules must be observed at all times:

• To avoid discharging static electricity, ground both yourself and any tools

before handling printed circuit boards, batteries, memory cards, and other

sensitive pieces of the equipment

• All electronic devices are sensitive to ESD (electrostatic discharge). To

avoid accidental damage while handling printed circuit boards, it is

recommended to wear a wrist strap, grounded to the chassis. The strap must

have a built-in protective resistor

• Anti-static, conductive plastic bags must be used for storage and transport

of PC boards in transit.

Safety Summary

Before replacing Units

Maintenance

All procedures for replacing units can be located by referring to the relevant

documentation.

Removing or replacing units with system power connected can cause injury to

personnel and damage to equipment. It is, therefore, of the utmost importance

that the power supply be fully disconnected, on the process side, before removal

or insertion of units takes place.

See Online Replacement of Unit on page 198 and I/O documentation.

It is recommended that a stock of suitable spare components be maintained to

avoid system downtime.

Ensure that back-up copies of the current application program are made at

regular, predetermined intervals to avoid system downtime.

Safety Summary (continued)

Operating Environment

Before the AC 800M Controller system is brought online, investigate which

environmental conditions are applicable. Take note in particular of the

following:

• The controller must not be exposed to conditions that exceed the values given

in the relevant technical specifications.

• The controller must not be used in an environment exposed to strong electrical

interference. Electrical machines can produce interference that exceeds levels

permitted for the equipment, for example during repair work.

• All products must be handled with appropriate precautions with regard to

electrostatic damage.

• The controller must not be exposed to direct sunlight.

Important Software Check

• Use the system’s fault-monitoring facilities to prevent accidents or mishaps.

• When in doubt, ALWAYS CHECK before executing changes.

Important Hardware Notice

• DO NOT, under any circumstances, disconnect the power supply to a

normally functioning system. Always use the correct system shut-down

procedure prior to disconnecting the power supply.

Signal Noise Due to Cables

Cables which may cause electrical interference (for example, power supply cables)

must not be installed adjacent to bus cables carrying fast digital signals. Ensure that

a minimum distance of 10 cm (4 in.) is provided between cables installed inside

cabinets.

Hazardous Electrical Supplies

Operational and maintenance procedures, during which personnel may come into

contact with high voltage, should only be carried out by personnel fully trained in

the maintenance of electrical equipment within those environments, and who are

fully aware of all risks involved.

Safety Summary

Electrostatic Sensitive Device

Devices labeled with this symbol require special handling precautions as

described in the installation section.

GENERAL

WARNINGS

Equipment Environment

All components, whether in transportation, operation or storage, must be

in a noncorrosive environment.

Electrical Shock Hazard During Maintenance

Disconnect power or take precautions to insure that contact with energized parts is avoided when servicing.

SPECIFIC

WARNINGS

Page 67: The AC 800M Controller and associated units must be unpowered and disconnected when being mounted onto a DIN-rail!

Page 68: It is not allowed to manipulate CEX bus baseplates in a powered

and running system. Before changing or removing a baseplate, all CEX

modules on that segment must be removed.

Page 72: AC 800M units must be disconnected from the power source

before removing them from a DIN-rail!

Page 72: It is not allowed to manipulate CEX bus baseplates in a powered

and running system. Before changing or removing a baseplate, all CEX

modules on that segment must be removed.

Page 78: For PM861/PM864/PM865/PM866 insert the RCU Link Termination plug TB852, at the RCU Link connector. The termination plug must

always be used for PM861/PM864/PM865/PM866 when running in single

configuration. When a redundant processor is running in a single configuration use the RCU Link Cable TK851, if the RCU Link Termination plug

TB852 is not available.

SPECIFIC

WARNINGS

(continued)

Page 124: The CI862 baseplate has no locking device. Insert only the

CI862 unit into this baseplate. Insertion of other unit types may cause

damage to the equipment.

Page 191: Before attempting maintenance or troubleshooting, read the

Safety Summary on page 13. Failure to do so could lead to personal

injury or damage to equipment.

Page 198: It is not allowed to manipulate CEX bus baseplates in a powered and running system. Before changing or removing a baseplate, all

CEX modules on that segment must be removed.

Page 429: Explosion hazard – Substitution of components may impair

suitability for Class I, Zone 2.

Page 429: Explosion hazard – Do not replace batteries unless the power

has been switched off or the area is known to be non-hazardous.

Page 430: Explosion hazard – Do not disconnect equipment unless the

power has been switched off or the area is known to be non-hazardous.

SPECIFIC

CAUTIONS

Page 68: To prevent damage to the pins, be sure the baseplate plugs and

sockets are fully aligned as the units interconnect. Under no circumstances use excessive force!

Page 68: It is essential that the locking device be placed in the LOCKED

position to avoid possible problems caused by vibration and/or intermittent

grounding.

Page 73: In order to provide adequate access and removal space, note

that the SLIDE sequence must be carried out on the unit baseplates adjacent to the unit that is to be removed.

Page 73: The unit baseplates are easily disconnected from each other by

gently prying them apart with a blade screwdriver (see Figure 23 on page

74).

SPECIFIC

CAUTIONS

(continued)

Page 76: Do not manipulate the locking device. ABB will take no responsibility for errors caused by manipulating locking devices.

-79 and Page 92: Do not place the internal back-up battery in the battery

holder until the AC 800M Controller has been powered-up normally and

the memory back-up function has been activated, that is, the B(attery)

LED flashes. If no normal power supply is connected to the processor unit

with the battery in place, then the CPU memory will immediately start to

consume battery power.

Page 90: Note that in redundant CPU configuration, COM3 and the electrical ModuleBus on the baseplate can not be used.

Page 91: Note that the RCU Link Cable TK851 must be used and can not

be replaced by a similar cable. Using another cable will disable the identification of the CPUs in the CB and Operator Station. When running in single configuration the RCU Link Cable TK851 might temporarily be used to

perform the function of a termination plug.

Page 98: Do not connect the two CEX-Bus segments, separated with

BC810, to each other with CEX-Bus extension cable TK850.

Page 98: In AC 800M High Integrity Controllers it is required that the external supply input of BC810 is connected and that the power supply is

strictly configured either according to Figure 33 or according to Figure 34

and nor is it allowed to change the configuration by way of for instance

individual circuit breakers between modules.

Page 99: Hot swap of the BC810 located next to a primary or single controller CPU, otherwise called “direct BC810”, might jeopardize the whole

controller and should not be performed unless every module on the

CEX-Bus are in a non-operating state. Note: In an AC 800M HI controller

this is unconditionally and intentionally leading to a shutdown of the controller.

Page 112: It is not possible to change the CI851 unit via hot swap and it is

not allowed to perform an online upgrade of firmware in a system containing CI851.

SPECIFIC

CAUTIONS

(continued)

Page 114: It is not possible to change the CI852 unit via hot swap and it is

not allowed to perform an online upgrade of firmware in a system containing CI852.

Page 118: Hot swap is supported for CI854A (not CI854).

Page 133: – 115 V for 110–120 V AC – 230 V for 220–240 V AC

(default position on delivery).

Page 141: To avoid error indications from SA/SB when single power supply is used, it is recommended to connect the input terminals SA/SB on

the CPU to +24 V, see Figure 47.

Page 143: Do not connect the TK821V020 cable until the AC 800M Controller has been powered-up normally and the memory back-up function

has been activated, that is, the B(attery) LED flashes. If no normal power

supply is connected to the PM8xx processor unit, the CPU memory will

immediately start to consume battery power when the cable is connected.

Page 157: When setting the IP address of the primary CPU in Control

Builder, the backup CPU must be turned off (powered down). Otherwise

the backup CPU will take over and you get disconnected.

Page 159: Note that the electrical ModuleBus can only be used for connection of S800 I/O when AC 800M is running in single CPU configuration.

Page 184: Note that a Backup CPU with severe communication errors on

the ModuleBus will be rejected (if ModuleBus is part of the HW configuration) and synchronized state will never be reached as long as error

remains.

Page 189: The RCU Link Cable must NEVER be removed from the primary Processor Unit during redundant operation. Removal of the cable

may cause the unit to stop.

Page 192: Due to the batteries being connected in parallel, it is necessary,

when using the SB821 external battery, to remove the internal battery

from the PM8xx in order to avoid reducing available memory back-up time

Safety Summary

SPECIFIC

CAUTIONS

(continued

Page 195: Due to the batteries being connected in parallel, it is necessary,

when using the SB821 external battery, to remove the internal battery

from the processor unit in order to avoid reducing available memory

back-up time.

-200 and Page 201: Reuse of CPU modules replaced from redundant configurations within the same control network, might cause control network

problems due to the MAC and IP address handling. See MAC and IP

Address Handling in Redundant Configuration on page 49. Such reuse

should not be fulfilled unless both the replaced module and the module

previously acting together with it in redundant configuration are known to

be restored from the previous mutual address swap. It is recommended to

set up an IP-config session and use the “Restore factory settings” option

subsequently followed by reassignment of the IP address or assignment

of a new IP address.

Page 200: Do not, under any circumstances, remove the RCU Link Cable

from the primary CPU now running in a single state. Removing the cable

might cause the CPU to stop.

Page 201: The unit baseplates are easily disconnected from each other by

gently prying them apart with a blade screwdriver (see Figure 23 on page

74).

Page 202: Do not replace the RCU link cable online in a previous version

than 5.0. The support for online replacement also depends on hardware

Product Revision levels. Please consult Release Notes (3BSE021377*)

for detailed information.

Page 428: If you use other power supplies, except SD82X and SD83X, to

provide the 24V d.c. for AC 800M it is required that they also are CE

marked, Underwriters Laboratories (UL ) listed and fulfill the LVD (SELVandPELV) criteria.

Page 428: The AC 800M modules are IP20 semi-protected equipment and

must be mounted in non-public localities.

About This User Manual

General

This book describes the hardware platform AC 800M. It also describes in detail how

to install, configure, operate and perform the necessary maintenance on all

equipment making up the AC 800M or AC 800M HI controllers.

Control Builder is used to configure and program the AC 800M controller, and is

referred to in this manual as Control Builder. For information on the controller

software, see controller software documentation.

For important information about late changes and work-arounds for known

problems, refer to the Release Notes (see Released User Manuals and Release Notes

on page 28).

User Manual Conventions

Microsoft Windows conventions are normally used for the standard presentation of

material when entering text, key sequences, prompts, messages, menu items, screen

elements, etc.

Any security measures described in this User Manual, for example, for user

access, password security, network security, firewalls, virus protection, etc.,

represent possible steps that a user of an 800xA System may want to consider

based on a risk assessment for a particular application and installation. This risk

assessment, as well as the proper implementation, configuration, installation,

operation, administration, and maintenance of all relevant security related

equipment, software, and procedures, are the responsibility of the user of the

800xA System

Warning, Caution, Information, and Tip Icons

This publication includes Warning, Caution, and Information where appropriate

to point out safety related or other important information. It also includes Tip to

point out useful hints to the reader. The corresponding symbols should be

interpreted as follows:

Although Warning hazards are related to personal injury, and Caution hazards are

associated with equipment or property damage, it should be understood that

operation of damaged equipment could, under certain operational conditions, result

in degraded process performance leading to personal injury or death. Therefore,

fully comply with all Warning and Caution notices.

Terminology

A complete and comprehensive list of terms is included in System 800xA System

Guide Functional Description (3BSE038018*). The listing includes terms and

definitions that apply to the 800xA System where the usage is different from

commonly accepted industry standard definitions and definitions given in standard

dictionaries such as Webster’s Dictionary of Computer Terms.

Electrical warning icon indicates the presence of a hazard which could result in

electrical shock.

Warning icon indicates the presence of a hazard which could result in personal

injury.

Caution icon indicates important information or warning related to the concept

discussed in the text. It might indicate the presence of a hazard which could

result in corruption of software or damage to equipment/property.

Information icon alerts the reader to pertinent facts and conditions.

Tip icon indicates advice on, for example, how to design your project or how to

use a certain function

Terms that uniquely apply to this User Manual are listed in the following table.

Table 1. Terminology

UL requirements for hazardous locations, the instructions in Appendix E, Standards

must be followed.

TÜV Approval

Units mentioned in this document are TÜV qualified for IEC 61508 SIL2 or SIL3 if

the

product is marked with the TÜV logo.

Released User Manuals and Release Notes

A complete list of all User Manuals and Release Notes applicable to System 800xA

is provided in System 800xA Released User Manuals and Release Notes

(3BUA000263*).

System 800xA Released User Manuals and Release Notes (3BUA000263*) is

updated each time a document is updated or a new document is released. It is in pdf

format and is provided in the following ways:

• Included on the documentation media provided with the system and published

to ABB SolutionsBank when released as part of a major or minor release,

Service Pack, Feature Pack, or System Revision.

• Published to ABB SolutionsBank when a User Manual or Release Note is

updated in between any of the release cycles listed in the first bullet.

A product bulletin is published each time System 800xA Released User Manuals

and Release Notes (3BUA000263*) is updated and published to ABB

SolutionsBank.

Product Overview

AC 800M – General

AC 800M is a hardware platform comprising individual hardware units, which can

be configured and programmed to perform multiple functions.

Once configured and programmed, the AC 800M effectively becomes the AC 800M

or AC 800M HI controller.

The hardware units that form the AC 800M and AC 800M HI Controllers are:

• Processor units (including baseplate)

(PM851/PM851A/PM856/PM856A/PM860/PM860A/PM861/PM861A/

PM864/PM864A/PM865/PM866/PM891)

• High Integrity Processor Unit

(consists of PM865 and SM810/SM811 with corresponding baseplates)

• Communication interfaces for different protocols (including baseplates)

(CI851/CI852/CI853/CI854/CI854A/CI855/CI856/CI857/CI858/CI860/

CI862/CI865/CI867/CI868/CI869/CI871/CI872/CI873)

• CEX-Bus Interconnection Unit

(BC810)

• Power supply units, providing various power output levels

SD831/SD832/SD833/SD834/SS823/SS832)

• Battery back-up unit

(SB821/SB822)

The SB821 is not supported with PM891.

PM851 is equivalent with PM856 unless stated otherwise.

PM851A is equivalent with PM851 unless stated otherwise.

PM856A is equivalent with PM856 unless stated otherwise.

PM860A is equivalent with PM860 unless stated otherwise

PM861A is equivalent to PM861 unless stated otherwise.

PM864A is equivalent to PM864 unless stated otherwise

When equipped with the specified Control Software, the AC 800M Controller acts

either as a stand-alone process controller, or as a controller performing local control

tasks in a control network consisting of many interconnected controllers, operator

stations and servers.

Various I/O systems can be connected to the AC 800M Controller, either directly

(S800 I/O) or via PROFIBUS DP or FOUNDATION Fieldbus.

The AC 800M is delivered without Control Software. To provide the controller

with Control Software, first load the firmware and then create the application

separately using the Control Builder M engineering tool.

The AC 800M Controller consists of a selection of units mounted on horizontal

DIN-rails, which can be housed within an enclosure. The majority of units consist of

a base mounting plate and removable cover attached with screws.

The baseplate, which is always mounted onto the DIN-rail, carries the majority of

the connections to processor, power supplies and communication interfaces, as well

as the connections to the external buses and systems.

The AC 800M Controller provides a cost-effective, low-maintenance solution for

applications ranging from small Programmable Logic Controller (PLC) to advanced

Distributed Control Systems (DCS) control applications and combined DCS, and

High Integrity systems control applications.

In the AC 800M High Integrity Controller, it is possible to run both non-SIL and

SIL classified applications. The AC 800M HI consist of PM865, SM810/SM811

and a High Integrity version of Control Software, and is also available in redundant

configuration. AC 800M HI requires the use of SIL certified S800 I/O units in SIL

classified applications. If the application is not SIL classified, standard S800 I/O

units can be used with AC 800M HI controller.

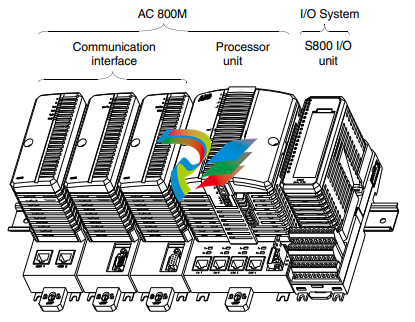

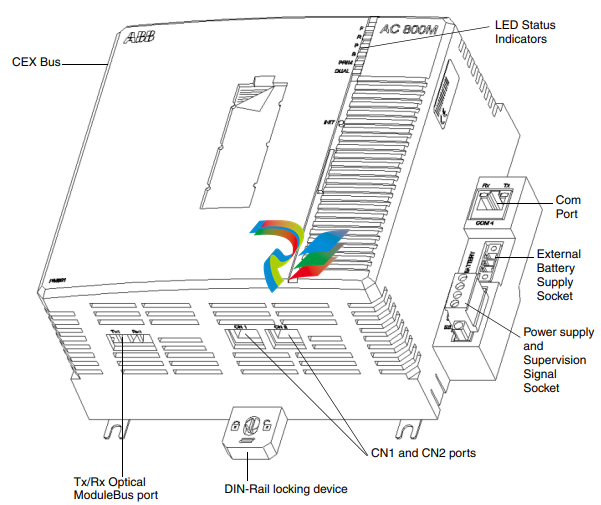

Figure 1 shows the physical appearance of an AC 800M Controller with an

S800 I/O Unit. This physical appearance does not apply to PM891.

Figure 1. Example of an AC 800M Controller (except PM891) with an S800 I/O

Unit

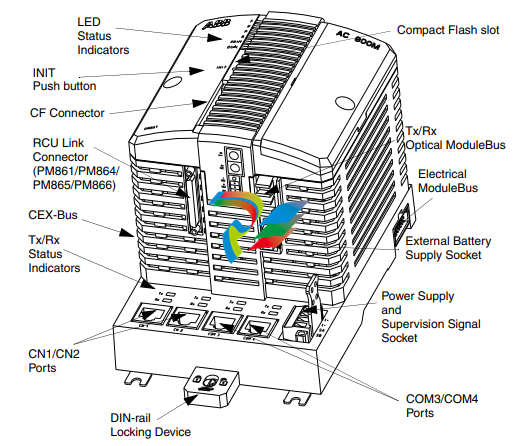

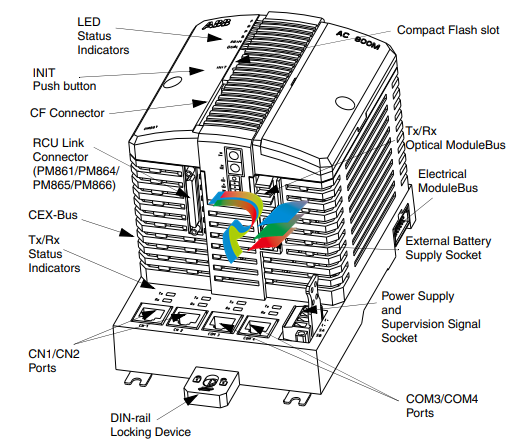

shows the PM861 processor unit that is part of the AC 800M controller.

This processor unit is different from PM891.

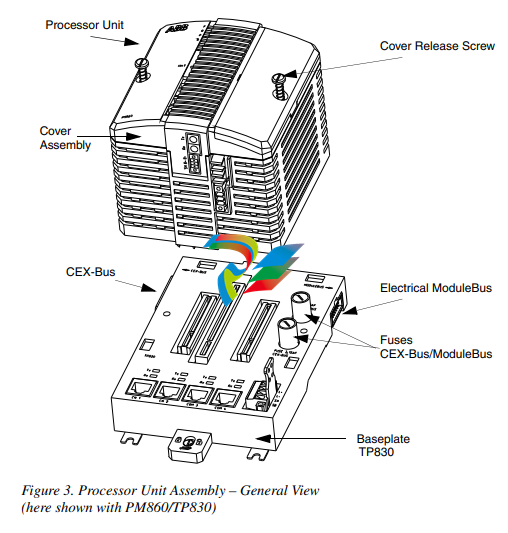

PM8xx/TP830 Processor Unit – General

Physically the PM8xx/TP830 Processor Unit consists of two basic parts:

• Processor Unit

(PM851/PM851A/PM856/PM856A/PM860/PM860A/PM861/PM861A/

PM864/PM864A/PM865/PM866) with processor and Power Supply boards.

• Baseplate (TP830), housing the unit termination board.

For the Functional Block Diagram, see Figure 4 on page 35 and

Figure 5 on page 36. The CPU board contains the microprocessor and the RAMmemory, controllers for all built-in communication interfaces, real-time clock, LED

indicators, INIT push button and a Compact Flash interface.

The main function of the power supply board is to generate isolated, circuit-proof

+5 V and +3.3 V supplies to the CPU and I/O units. The board also contains optoisolated RS-232C drivers/receivers for the service port, together with a back-up

battery holder for memory/real time clock, (RTC).

The termination board, housed in the TP830 Baseplate, is where the majority of

the external connections terminates. The board is grounded to the DIN-rail through

of the metallic components of the housing. The termination board is provided with

screw terminals for power supply and redundant power supply monitoring, with

RJ45 connectors for the control network and serial port, a connector for the service

port, the electrical ModuleBus and the CEX-Bus.

The 24 V DC supply, connected to the TP830 Baseplate, powers all the units on the

CEX-Bus and the electrical ModuleBus.

In single CPU configuration, it is possible to connect an S800 I/O cluster directly to

the built-in electrical ModuleBus plug located on the right hand side of the TP830

Baseplate.

The processor unit has a communication expansion bus connector located on

the left-hand side of the TP830 Baseplate. This CEX-Bus provides for extending

the on-board communication ports with additional communication interfaces

PROFIBUS DP, FOUNDATION Fieldbus H1, FOUNDATION Fieldbus High Speed

Ethernet and dual RS-232C ports are some examples of unit types available for

connection to the CEX-Bus. It is possible to use redundant communication

interfaces, for example PROFIBUS DP.

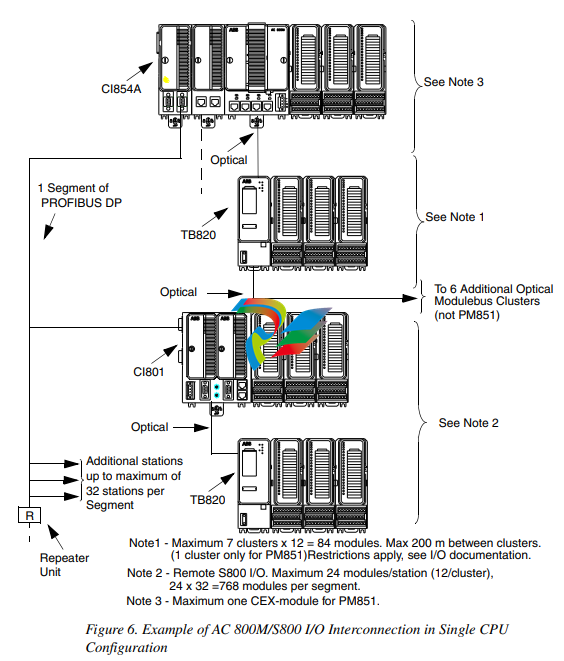

Figure 6 on page 38 provides examples of various ways to connect the S800 I/O

units. It can be seen, at the top right-hand area of Figure 6 on page 38, that one

cluster (or group) of units (maximum number of units per cluster is 12) is connected

to the electrical ModuleBus of an AC 800M Controller. However, a further seven

clusters (each comprising up to 12 units) can be added to the optical ModuleBus,

thus achieving a total count of 96 units per AC 800M Controller when using only

the ModuleBus.

To the left on Figure 6 on page 38, there is a PROFIBUS DP segment. This allows

for a large increase in the numbers of units connected to each AC 800M Controller.

Here the segment is shown as having an FCI unit (type CI801), connected to the

PROFIBUS DP network. The use of FCI units allows the selection of units from

several I/O families.

Figure 7 on page 39 shows another example for I/O units based on a

FOUNDATION Fieldbus High Speed Ethernet (FF HSE).

For further examples refer to the relevant documentation for the I/O system in

question.

Connecting S800 I/O units (using the ModuleBus) to an AC 800M Controller

mounted with a PM851/PM851A processor unit is restricted to, one electrical

ModuleBus cluster and one optical ModuleBus cluster

PM891 Processor Unit – General

PM891 is a high performance controller, which is capable of handling applications

with high requirements.

PM891 connects to the S800 I/O system through the optical Modulebus. It can act

as a stand-alone Process Controller, or as a controller performing local control tasks

in a control network.

Two PM891 controllers can function together as a redundant pair, with one PM891

acting as the primary controller and the other acting as the backup. The backup

controller takes over the process controller tasks if any hardware error occurs in the

primary controller.

The control network connectivity is obtained by two built in IEEE802.3 Ethernet

channels on PM891.

PM891 also provides a communication expansion bus (CEX-Bus) to which a

number of expansion modules can be connected. These modules offers connectivity

to a wide range of field bus and I/O systems. In case of a redundant pair, both

PM891s are connected to the same CEX-Bus and one of them can control the

modules.

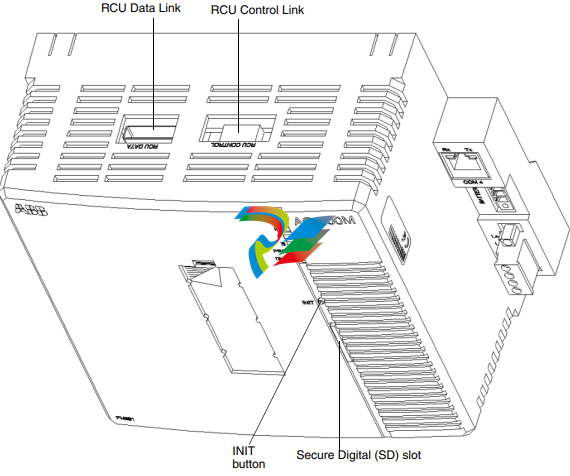

Physically, the PM891 Processor Unit consists of:

• Connector for power supply and status signals (L+, L-, SA, SB).

• DB25 connector for Electrical CEX-Bus.

• External battery connector.

• RJ45 connectors for the two Ethernet channels.

• One Com port.

• Optical Modulebus connector for connection to a maximum of seven clusters,

with 12 non-redundant or six redundant modules (that is, 7×12 = 84 modules).

• Connectors for Redundancy Link.

• SD (Secure Digital) memory connector.

• LEDs.

• Pushbutton reset switch.

shows the front view, Figure 9 shows the top view, and Figure 10 shows the

bottom view of PM891.

Screw terminals are provided for connections to the power supply and the external

battery.

The 24 V DC power supply powers all the units on the CEX-Bus. The optical

module clusters are powered independently.

PM891/PM86x/TP830 Processor Unit – Redundancy

Processor unit redundancy is available for PM861, PM864, PM865, PM866, and

PM891. In this case, the controller contains two processor units, each including

memory for system and application software. One unit is acting as primary, the

other is backup (hot stand-by). The primary processor unit controls the process. The

backup stands by, ready to take over in case of a fault in the primary. The

changeover is done bumplessly and in less than 10 ms. During the changeover, the

process outputs are frozen.

Following a changeover, the system operates as a system without redundancy with

only one processor unit in operation. You can replace the malfunctioning processor

unit while the system is running. After the replacement is carried out, the system

once again has a redundant processor unit.

If an error arises in the backup unit, you can also replace the backup unit while the

system is running.

Errors which occur in the backup unit can never affect the primary unit’s operation.

The primary unit and the backup unit are logically separated from one another.

Hardware errors in the primary processor unit cause the system to perform a correct

changeover. These hardware errors are single errors.

The application programming and the communication are totally unaffected by the

redundancy.

PM86x/TP830 Redundancy

The PM861/PM864/PM865/PM866 has an RCU Link Connector for connecting the

RCU Link Cable (see Figure 2 on page 32). In a redundant system the two processor

units are linked together with the RCU Link Cable (max 1 m). Both processor units

are also connected to the same CEX-Bus and either of the two can control the

expansion units (see Figure 29 on page 93).

S800 I/O units are connected to the two CPUs via the optical ModuleBus and two

TB840 cluster modems on each S800 I/O cluster (see Figure 55 on page 161). The

built-in electrical ModuleBus on the TP830 baseplate cannot be used for connecting

S800 I/O in a redundant system.

The serial port, COM3 on the baseplate TP830, cannot be used in redundant CPU

configuration.

Leave a comment

Your email address will not be published. Required fields are marked *