parkerRack power supply unit

» From the Vibro-Meter ® product line

» Power supply unit for VM600 system rack (6U)

» High performance

» Wide input voltage range

» Over-voltage protection

» Continuous short-circuit proof

» Minimal derating within the operating

temperature range

» 6U height

» Compact design

» Fully VME compatible

» Conforms to EC standards for EMC

» Up to two RPS6U rack power supply units can be

installed in a VM600 system rack (ABE04x)

Rack power supply unit (RPS6U)

for a VM600 system rack (ABE04x)

DESCRIPTION

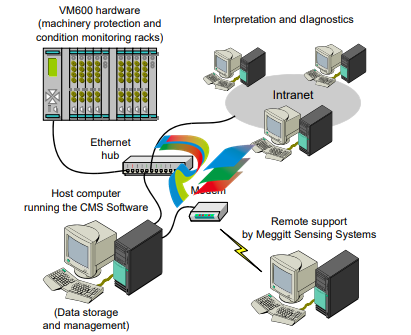

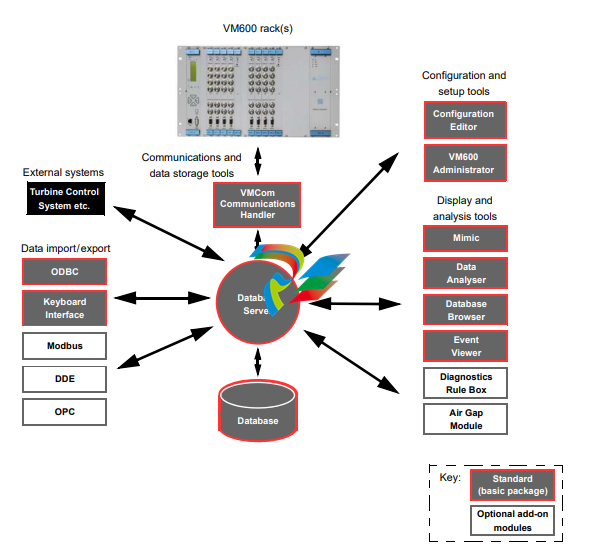

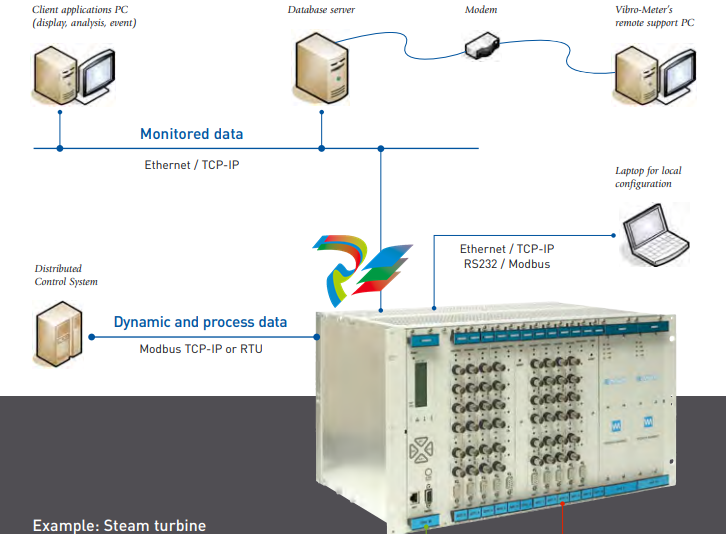

The RPS6U rack power supply units are designed for

use in the VM600 series of machinery protection

systems and condition and performance monitoring

systems, from Meggitt Sensing Systems’ Vibro-Meter

product line.

The RPS6U is installed in the front of a VM600

system rack (ABE04x) with a standard height of 6U

and connects directly to the rack backplane via two

connectors. The power supply provides +5 VDC and

±12 VDC power to all cards in the rack via the rack

backplane.

One or two RPS6U power supplies can be installed in

a VM600 system rack. A rack can have two RPS6U

units installed for different reasons: to supply power to

a rack with many cards installed, non-redundantly, or

to supply power to a rack with fewer cards installed,

redundantly. Typically, the cutoff point is when nine

rack slots or fewer are used

Rack power supply unit

RPS6U

2 / 15 © Meggitt SA / 268-011 / Version 9 / 23.04.2015 / E

DESCRIPTION (continued)

When a VM600 system rack is operating with two

RPS6U units for power supply redundancy, if one

RPS6U fails, the other will provide 100% of the power

requirement and the rack will continue to operate,

thereby increasing the availability of the machinery

monitoring system.

Various versions of the RPS6U exist, allowing a rack

to be powered from external AC or DC mains supplies

with a range of supply voltages.

A power supply check relay, available at the rear of a

VM600 rack, indicates that the power supplies are

operating normally. Refer to the ABE040 and ABE042

VM600 system rack and ABE056 VM600 slimline

rack data sheets for additional information on power

supply check relays.

In applications where the VM600 rack is powered by

an AC mains supply, an auxiliary sensor power supply

(ASPS) can also be included in the rack. The ASPS

provides +24 VDC outputs which can be used by

external hardware such as front-end transducers,

signal conditioners and galvanic separation units.

For specific applications, contact your nearest Meggitt

Sensing Systems representative.

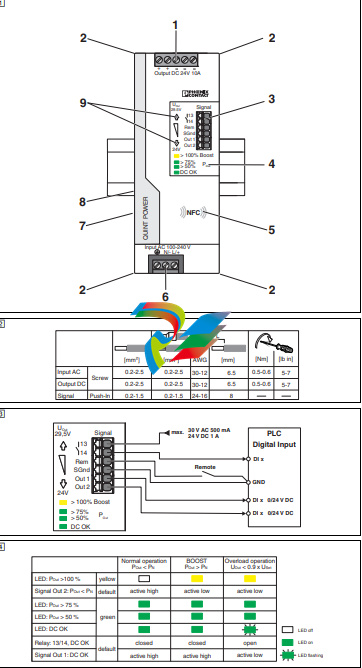

SPECIFICATIONS

Power supply

Input

Input voltage range (Vi

nom.) : See Ordering information on page 12

Mains frequency variations : See Ordering information on page 12

Efficiency : See Ordering information on page 12

Output

Nominal output (Vo nom. / Io max.)

• DC output 1 : +5 VDC / +35 A

• DC output 2 : +12 VDC / +6 A

• DC output 3 : −12 VDC / −2 A

Stability of output voltage Uo

under full load conditions

: ≤ ±0.2%

Ripple (bandwidth 20 MHz) : ≤ 50 mVpp

Output current limitation : 35 A (electronic current limiter)

Output overvoltage protection : 5.9 to 6.7 V (factory set)

Power derating : 1%/°C from 60 to 70°C

Power

Rated power : 300 W

Rated supply voltage : See Ordering information on page 12

Environmental

According to IEC 60068-2 recommendations

Operating temperature range : −25 to +65°C (−13 to +149°F)

Storage temperature range : −40 to +85°C (−40 to +185°F)

Humidity : ≤ 95% non-condensing

Vibration : 10 to 2000 Hz, 5 g, 2 h in each direction

Shock : 100 g, 6 ms, half-sine pulse

Physical

Dimensions : 6 U / 12 HP (TE) x 187 mm

Weight (approx.) : 2.1 kg (4.63 lb)

Safety

Applicable safety standards : UL 1950, CSA 22.2#234, IEC 950, EN 60950

Marking : See Ordering information on page 12

TOLERANCE TO MICRO-INTERRUPTIONS IN THE SUPPLY INPUT

The table below shows the maximum permissible duration of a power cut which will not cause MPC4 cards to be reset.

This value depends on the number of MPC4 cards and RPS6U units installed in the VM600 rack.

Number of RPS6U power supplies in VM600 system rack

Number of MPC4 cards in

VM600 system rack

1 unit 2 units

2 cards 190 ms 250 ms

12 cards 10 ms 20 ms

S

ORDERING INFORMATION (continued)

Rear panels

To order please specify the type (Rear panel), designation and ordering number from the table below

(see also the drawings (a) to (k) in Associated rear panels on pages 4 to 9)

Drawing Designation Ordering number

(a)

One DC input with screw-terminal connector that provides a common input to the

RPS6U power supplies.

This rear panel is equivalent to Rear panel for RPS6U power supply order option code F200.

200-582-920-NHh

(b)

Two DC inputs with screw-terminal connectors that provide individual inputs to the

RPS6U power supplies.

This rear panel is equivalent to Rear panel for RPS6U power supply order option code F930.

200-582-993-NHh

(c)

One DC input with screw-terminal connector that provides a common input to the

RPS6U power supplies. Also provides a special earth terminal (identified as M.A.L.T.).

This rear panel is equivalent to Rear panel for RPS6U power supply order option code F220.

200-582-922-NHh

(d)

Two DC inputs with screw-terminal connectors that provide a common input to the

RPS6U power supplies.

Supports redundant external power-supply systems.

This rear panel is equivalent to Rear panel for RPS6U power supply order option code F900.

200-582-990-NHh

(e)

One AC input (120/230 VAC) with mains socket and on/off switch that provides a common

input to the RPS6U power supplies.

This rear panel is equivalent to Rear panel for RPS6U power supply order option code F100.

200-582-910-NHh

(f)

One AC input (120/230 VAC) with screw-terminal connector, on/off switch and rear-panel fuses

that provides a common input to the RPS6U power supplies.

This rear panel is equivalent to Rear panel for RPS6U power supply order option code F110.

200-582-911-NHh

(g)

One AC input (120/230 VAC) with screw-terminal connector and rear-panel fuses that provides

a common input to the RPS6U power supplies.

This rear panel is equivalent to Rear panel for RPS6U power supply order option code F120.

200-582-912-NHh

(h)

Two AC inputs (120 VAC only) with mains sockets and on/off switches that provide a common

input to the RPS6U power supplies.

Supports redundant external power-supply systems.

This rear panel is equivalent to Rear panel for RPS6U power supply order option code F620.

200-582-962-NHh

(i)

Two AC inputs (120/230 VAC) with mains sockets and on/off switches that provide individual

inputs to the RPS6U power supplies.

This rear panel is equivalent to Rear panel for RPS6U power supply order option code F630.

200-582-963-NHh

(j)

Two AC inputs (230 VAC only) with mains sockets and on/off switches that provide a common

input to the RPS6U power supplies.

Supports redundant external power-supply systems.

This rear panel is equivalent to Rear panel for RPS6U power supply order option code F600.

200-582-960-NHh

(k)

Two AC inputs (120/230 VAC) with screw-terminal connectors, on/off switches and rear-panel

fuses that provide individual inputs to the RPS6U power supplies.

This rear panel is equivalent to Rear panel for RPS6U power supply order option code F150.

200-582-915-NHh

(l)

Two AC inputs (120/230 VAC) with screw-terminal connectors and rear-panel fuses that

provide individual inputs to the RPS6U power supplies.

This rear panel is equivalent to Rear panel for RPS6U power supply order option code F160.

200-582-916-NHh

(m)

One AC input (120/230 VAC) with mains socket and on/off switch and one DC input with screwterminal connector that provide individual inputs to the RPS6U power supplies.

This rear panel is equivalent to Rear panel for RPS6U power supply order option code F700.

200-582-970-NHh

Rack power supply unit

RPS6U

14 / 15 © Meggitt SA / 268-011 / Version 9 / 23.04.2015 / E

Notes

All AC input rear panels are supplied with a mains power supply lead (no lead is supplied for the DC input versions). See Mains power

supply leads (power cords) on page 14.

AC input rear panels with mains sockets have an IEC type C14 connector (IEC 60320) that mates with the plug (type C13) used by the

supplied mains power supply leads.

Rear panels with one input – (a), (b), (c), (d), (e), (f) and (g) – are 2 slots wide / 8 HP (TE).

Most rear panels with two inputs – (h), (i), (j), (k) and (l) – are 4 slots wide / 16 HP (TE).

However, the rear panel with AC and DC inputs – (m) is 2 slots wide / 8 HP (TE).

(The width of 19″ rack is measured in horizontal pitch (HP) units of 5.08 mm (0.2″), also known as standard width (TE) units. For the

ABE04x rack, a one slot wide (one card position) blank panel corresponds to 4 HP (TE), a two slot wide blank panel corresponds to 8 HP (TE)

and a four slot wide blank panel corresponds to 16 HP (TE).)

Rear panels with two input connectors that provide a common input to the RPS6U power supplies – (d), (h) and (j) – installed in the rack can

be used with a redundant external power-supply system.

For additional information on the Rear panel for RPS6U power supply order option codes (Fxxx), refer to the ABE040 and ABE042 VM600

system rack and ABE056 VM600 slimline rack data sheets.

For the Ordering number:

“NHh” represents the hardware version.

“N” is either “0” for a rear panel according to (and marked) CE low voltage directive or “2” for a rear panel according to (and marked) CCSAUS.

“H” increments are for major modifications that can affect product interchangeability.

“h” increments are for minor modifications that have no effect on interchangeability

Mains power supply leads (power cords)

To order please specify the type (Mains power supply lead), designation and ordering number from the table below

Designation Ordering number

None – no mains cable.

This rear panel is equivalent to Mains power supply lead (power cord) order option code H00. —

No plug – flying lead with wire-end ferrules.

This rear panel is equivalent to Mains power supply lead (power cord) order option code H01. 957.18.13.0020

J plug as per SEV 1011 (Switzerland).

This rear panel is equivalent to Mains power supply lead (power cord) order option code HCH. 957.18.13.0021

E+F plug as per CEE7/VII (Europe, Russia, Ukraine).

This rear panel is equivalent to Mains power supply lead (power cord) order option code HEU. 957.18.13.0022

G plug as per BS 1363 (UK, Hong Kong, Malaysia, Singapore).

This rear panel is equivalent to Mains power supply lead (power cord) order option code HUK. 957.18.13.0023

B plug as per JIS 8303 (Japan).

This rear panel is equivalent to Mains power supply lead (power cord) order option code HJP. 957.18.13.0024

B plug as per NEMA 5-15 (United States, Canada).

This rear panel is equivalent to Mains power supply lead (power cord) order option code HUS. 957.18.13.0025

Notes

The mains cables (power cords) are for the AC input version of the RPS6U power supply. No cables are available for the DC input versions.

Rear panels with two AC inputs for independent mains supplies (ordering numbers: 200-582-96x-NHh) require two mains cables.

For additional information on the Mains power supply lead (power cord) order option codes (Hxx), refer to the ABE040 and ABE042 VM600

system rack and ABE056 VM600 slimline rack data sheets.

Headquartered in the UK, Meggitt PLC is a global engineering group specializing in extreme environment components and smart sub-systems for aerospace,

defence and energy markets.

Meggitt Sensing Systems is the operating division of Meggitt specializing in sensing and monitoring systems, which has operated through its antecedents since 1927

under the names of ECET, Endevco, Ferroperm Piezoceramics, Lodge Ignition, Sensorex, Vibro-Meter and Wilcoxon Research. Today, these operations are

integrated under one strategic business unit called Meggitt Sensing Systems, headquartered in Switzerland and providing complete systems, using these renowned

brands, from a single supply base.

The Meggitt Sensing Systems facility in Fribourg, Switzerland was formerly known as Vibro-Meter SA, but is now Meggitt SA. This site produces a wide range of

vibration and dynamic pressure sensors capable of operation in extreme environments, leading-edge microwave sensors, electronics monitoring systems and

innovative software for aerospace and land-based turbo-machinery.

All statements, technical information, drawings, performance rates and descriptions in this document, whilst stated in good faith, are issued for the sole

purpose of giving an approximate indication of the products described in them, and are not binding on Meggitt SA unless expressly agreed in writing.

Before acquiring this product, you must evaluate it and determine if it is suitable for your intended application. Unless otherwise expressly agreed in

writing with Meggitt SA, you assume all risks and liability associated with its use. Any recommendations and advice given without charge, whilst given in

good faith, are not binding on Meggitt SA.

Meggitt Sensing Systems takes no responsibility for any statements related to the product which are not contained in a current Meggitt Sensing Systems

publication, nor for any statements contained in extracts, summaries, translations or any other documents not authored by Meggitt Sensing Systems. We

reserve the right to alter any part of this publication without prior notice.

In this publication, a dot (.) is used as the decimal separator and thousands are separated by thin spaces. Example: 12 345.678 90.