Vibro-Meter ® VM600 CPUM and IOCN modular CPU card and input/output card

KEY FEATURES AND BENEFITS

• From the Vibro-Meter® product line

• VM600 CPUM/IOCN rack controller and

communications interface card pair with

support for Modbus RTU/TCP and PROFINET,

and a front-panel display

• “One-Shot” configuration management of

protection cards (MPC4 and AMC8) in a

VM600 rack using an Ethernet or RS-232 serial

connection to a computer running the

VM600 MPSx software

• Front-panel display for visualisation of

monitored outputs and alarm limits from

protection cards

• Front-panel alarm reset (AR) button

• VM600 MPS rack (CPUM) security

• Industry standard fieldbus communications

interfaces: Modbus RTU/TCP and PROFINET

• Two Ethernet connections and up to three

serial connections (RS-232 / RS-422 / RS-485)

can run simultaneously

• Communications redundancy with multiple

fieldbuses: Ethernet and/or serial

KEY BENEFITS AND FEATURES (continued)

• VM600 system event and measurement event

logs available via the VM600 MPSx software

• Supports live insertion and removal of

protection cards (“hot-swapping”) with

automatic configuration

• Ethernet (100 Mbps) communication

• Front-panel status indicators (LEDs)

• Compatible with all VM600 ABE04x

system racks

APPLICATIONS

• Rack controller for a VM600 system

• Communications gateway between VM600

and third-party systems, such as a DCS or PLC

• Enables sharing of measurement data from

VM600 monitoring cards in machinery

protection, condition monitoring and/or

combustion monitoring applications

Information contained in this document may be subject to export control regulations of the European Union, USA or other countries.

Each recipient of this document is responsible for ensuring that transfer or use of any information contained in this document

complies with all relevant export control regulations. ECN N/A.

DESCRIPTION

Introduction

The VM600 CPUM and IOCN modular CPU card

and input/output card is a rack controller and

communications interface card pair that acts as

a system controller and data communications

gateway for a VM600 rack-based machinery

protection system (MPS) and/or condition

monitoring system (CMS) from Meggitt’s

Vibro-Meter® product line.

Different versions of CPUx/IOCx card pair

Different versions of CPUx/IOCx rack controller

and communications interface card pair are

available, as follows:

• The CPUM/IOCN is the original version with a

front-panel display and support for

Modbus RTU/TCP and PROFINET

(PNR 200-595-VVV-VVV).

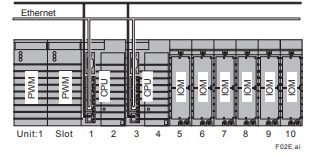

• The CPUR/IOCR is a version with rack controller

redundancy and support for Modbus RTU/TCP

(PNR 600-007-VVV-VVV).

• The CPUR2/IOCR2 is a version with

mathematical processing of fieldbus data and

support for Modbus TCP and PROFIBUS DP

(PNR 600-026-000-VVV).

VM600 rack-based monitoring systems

The Vibro-Meter® VM600 rack-based monitoring

system is part of Meggitt’s solution for the

protection and monitoring of rotating machinery

used in the power generation and oil & gas

industries. The VM600 is recommended when a

centralised monitoring system with a medium to

large number of measurement points (channels)

is required. It is typically used for the monitoring

and/or protection of larger machinery such as

gas, steam and hydro turbines, and generators,

smaller machines such as compressors, fans,

motors, pumps and propellers, as well as balanceof-plant (BOP) equipment.

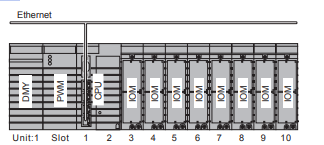

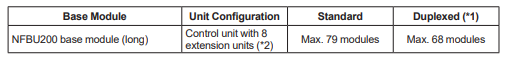

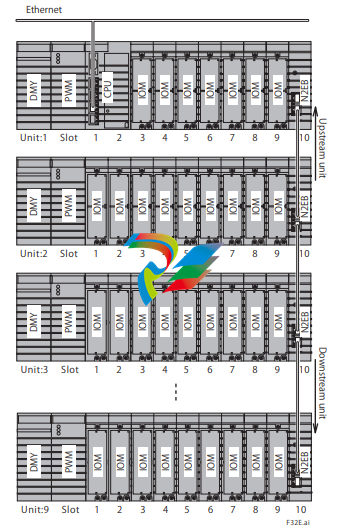

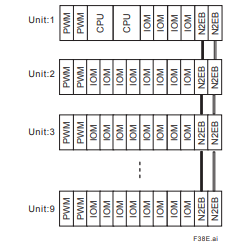

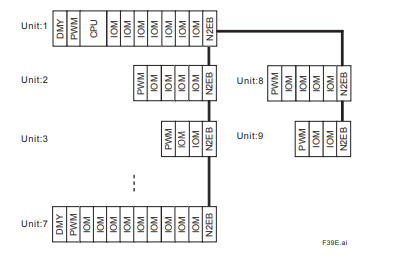

A VM600 system consists of a 19″ rack, a rack

power supply and one or more monitoring card

pairs. Optionally, relay cards and rack controller

and communications interface cards can also be

included.

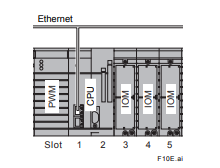

Two types of VM600 rack are available: a VM600

ABE04x system rack (6U) that can house up to 12

monitoring card pairs, and a VM600 ABE056

slimline rack (1U) that can house 1 monitoring

card pair. VM600 racks are typically mounted in

standard 19″ rack cabinets or enclosures installed

in an equipment room.

Different VM600 monitoring cards are available

for machinery protection, condition monitoring

and/or combustion monitoring applications. For

example, machinery protection cards such as the

MPC4/IOC4T machinery protection card pair and

AMC8/IOC8T analogue monitoring card pair,

and condition monitoring cards such as the

XMV16/XIO16T monitoring card pair for vibration

and XMC16/XIO16T monitoring card pair for

combustion.

The RLC16 relay card is an optional card used to

provide additional relays when the four relays per

MPC4/IOC4T or AMC8/IOC8T card pair are not

enough.

The CPUx/IOCx rack controller and

communications interface card pairs (CPUM/

IOCN, CPUR/IOCR or CPUR2/IOCR2) are optional

cards used to provide additional VM600 system

functionality such as configuration management,

“hot-swapping” with automatic reconfiguration,

front-panel display, CPUx/IOCx card pair

redundancy, fieldbus data processing, frontpanel alarm reset (AR) button, MPS rack (CPUx)

security, system event and measurement event

logging, fieldbus communications (Modbus,

PROFIBUS and/or PROFINET) and/or

communications redundancy.

Note: Different versions of CPUx/IOCx rack

controller and communications interface card

pair support different combinations of VM600

system functionality.

VM600 rack-based monitoring systems

complement the VibroSmart® module-based

distributed monitoring systems that are also

available from Meggitt’s Vibro-Meter® product

line.

DESCRIPTION (continued)

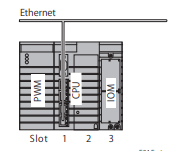

CPUM/IOCN card pair and VM600 racks

The CPUM/IOCN card pair is used with a VM600

ABE04x system rack and a CPUM card can be

used either alone or with an associated IOCN

card as a card pair, depending on the

application/system requirements.

The CPUM is a double-width card that occupies

two VM600 rack slots (card positions) and the

IOCN is a single-width card that occupies a single

VM600 slot. The CPUM is installed in the front of the

rack (slots 0 and 1) and an associated IOCN is

installed in the rear of the rack in the slot directly

behind the CPUM (slot 0). Each card connects

directly to the rack’s backplane using two

connectors.

Note: The CPUM/IOCN card pair is compatible

with all VM600 ABE04x system racks.

CPUM rack controller and communications

interface functionality

The modular, highly versatile design of the CPUM

means that all VM600 rack configuration, display

and communications interfacing can be

performed from a single card in a “networked”

rack. The CPUM card acts as a “rack controller”

and allows an Ethernet link to be established

between the rack and a computer running one

of the VM600 MPSx software packages (MPS1 or

MPS2).

The CPUM front panel features an LCD display

that shows information for the CPUM itself and for

protection cards in a VM600 rack. The SLOT and

OUT (output) keys on the CPUM front panel are

used to select which signal to display.

As a fieldbus communications interface for a

VM600 monitoring system, the CPUM

communicates with MPC4 and AMC8 cards via

the VME bus and with XMx16/XIO16T card pairs

via an Ethernet link in order to obtain

measurement data and then share this

information with third-party systems such as a DCS

or PLC.

LEDs on the CPUM front panel indicate the OK,

Alert (A) and Danger (D) status for the currently

selected signal. When Slot 0 is selected, the LEDs

indicate the overall status of the whole rack.

When the DIAG (diagnostic) LED shows green

continuously, the CPUM card is operating

normally, and when the DIAG LED blinks, the

CPUM card is operating normally but access to

the CPUM card is restricted due to VM600 MPS

rack (CPUM) security.

The ALARM RESET button on the front panel of the

CPUM card can be used to clear the alarms

latched by all protection cards (MPC4 and

AMC8) in the rack. This is a rack-wide equivalent

of resetting alarms individually for each card using

discrete signal interface alarm reset (AR) inputs or

VM600 MPSx software commands.

The CPUM card consists of a carrier board with

two PC/104 type slots that can accept different

PC/104 modules: a CPU module and an optional

serial communications module.

All CPUM cards are fitted with a CPU module that

supports two Ethernet connections and two serial

connections. That is, both the Ethernet redundant

and serial redundant versions of the card.

The primary Ethernet connection is used for

communication with the VM600 MPSx software

via a network and for Modbus TCP and/or

PROFINET communications. The secondary

Ethernet connection is used for Modbus TCP

communications. The primary serial connection is

used for communication with the VM600 MPSx

software via a direct connection. The secondary

serial connection is used for Modbus RTU

communications.

Optionally, a CPUM card can be fitted with a

serial communications module (in addition to the

CPU module) in order to support additional serial

connections. This is the serial redundant version of

the CPUM card.

The CPUM module’s primary Ethernet and serial

connections are available via connectors (NET

and RS232) on the front panel of the CPUM.

However, if the associated IOCN card is used, the

primary Ethernet connection can be routed to a

connector (1) on the front panel of the IOCN

(instead of the connector on the CPUM (NET)).

When the associated IOCN card is used, the

secondary Ethernet and serial connections are

available via connectors (2 and RS) on the front

panel of the IOCN.

IOCN card

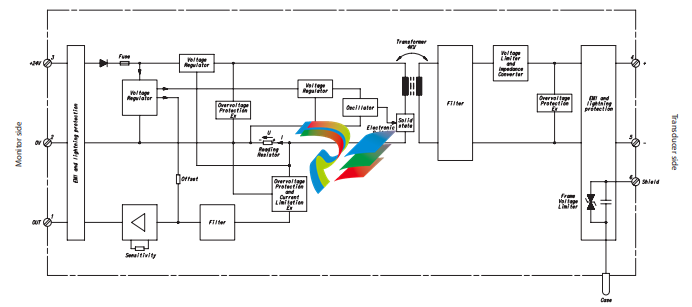

The IOCN card acts as a signal and

communications interface for the CPUM card. It

DESCRIPTION (continued)

also protects all inputs against electromagnetic

interference (EMI) and signal surges to meet

electromagnetic compatibility (EMC) standards.

The IOCN card’s Ethernet connectors (1 and 2)

provide access to the primary and secondary

Ethernet connections, and the serial connector

(RS) provides access to the secondary serial

connection.

In addition, the IOCN card includes two pairs of

serial connectors (A and B) that provide access to

the additional serial connections (from the

optional serial communications module) that can

be used to configure multi-drop RS-485 networks

of VM600 racks.

Front-panel display

The CPUM front panel features an LCD display

that uses display pages to show important

information for the cards in a VM600 rack. For the

CPUM itself, card run time, rack system time, rack

(CPUM) security status, IP address/netmask and

version information are displayed. While for MPC4

and AMC8 cards, measurements, card type,

version and run time are displayed.

For MPC4 and AMC8 cards, the level of the

selected monitored output is displayed on a

bargraph and numerically, with the Alert and

Danger levels also indicated on the bar-graph.

Measurement identification (slot and output

number) is shown at the top of the display.

VM600 MPS rack (CPUM) security

The CPUM supports features that can be used to

limit the functionality of a VM600 rack’s

machinery protection system (MPS) that is

available via the system Ethernet connections of

a CPUM/IOCN card pair. Enabling VM600 MPS

rack (CPUM) security helps to reduce the

possibility of interference in the machinery

protection function of the rack itself and in the

machinery being monitored. Accordingly, CPUM

rack security makes it easier for operators to

comply with international security/critical

infrastructure regulations.

The security features consists of two specific levels

of protection integrated in the CPUM card: CPUM

access lock (a “hardware” security feature) and

VM600 MPSx password validation (a “software”

security feature). Refer to the VM600 machinery

protection system (MPS) hardware manual and

the VM600 MPSx software manuals for further

information.

VM600 event logging

The CPUM card automatically logs VM600 system

events and measurement events to non-volatile

memory in order to provide valuable information

on the operating history of a system. Up to 10000

of the most recent events are stored on the card

for download as user-readable event log files

using the VM600 MPSx software.

Software

The CPUM/IOCN is software configurable using

the CPUM Configurator software.

The VM600 MPSx software supports the

configuration and operation of MPC4/IOC4T

card pairs for machinery protection applications,

including the processing and presentation of

measurement data for analysis. VM600 MPSx is

also used to configure and manage CPUM/IOCN

card pairs.

Note: The VM600 MPSx software is from the

Vibro-Meter® product line.

Applications information

The VM600 CPUM/IOCN rack controller and

communications interface card pair is

recommended for applications using multiple

monitoring cards in a VM600 rack.

The rack controller functionality makes it easier to

work with a VM600 machinery monitoring system –

for installation, configuration, management and

general operation. The CPUM/IOCN can

manage the configuration of MPC4/IOC4T and

AMC8/IOC8T card pairs, including hot-swapping.

It can also manage the configuration of XMx16/

XIO16T card pairs, eliminating the need for a

VibroSight Server in certain applications.

The communications interface functionality

makes it easy to further process and share data

from the monitoring cards (MPC4, AMC8 and/or

XMC16) in a VM600 machinery protection,

condition monitoring and/or combustion

monitoring system with third-party systems such as

a DCS or PLC using industry standard fieldbuses.

For further information, contact your local

Meggitt representative.

Processing functions

Rack controller

• VM600 monitoring card configuration

management

: Acts as a rack controller that manages the configuration of MPC4/

IOC4T and AMC8/IOC8T card pairs, including support for

“hot-swapping” with automatic configuration.

Can also manage the configuration of XMx16/XIO16T card pairs,

for applications that do not require a VibroSight Server.

• Front-panel display : LCD display that uses display pages to show important information

for the cards in a VM600 rack:

• Card run time, rack system time, rack (CPUM) security status,

IP address/netmask and version info are displayed for the CPUM.

• Measurements (bargraph with alarm levels, and numerically),

card type, version, and run time are displayed for the MPC4 and

AMC8 cards in the rack.

• Fieldbus data processing

(mathematical processing)

: Further processing of system data (measurement data and status

information) before being shared by fieldbus.

The further processing supported includes basic mathematical

functions such as arithmetic and logical operations, data selection,

comparison, min/max and scaling functions, bit manipulation and

packing/unpacking functions, and many supporting functions.

There is also a data freeze detection function that can be used to

help detect if a data value has stopped being updated.

• Alarm reset : CPUM front-panel button used to manually clear the alarms (and

relays) latched by MPC4/IOC4T and AMC8/IOC8T card pairs in the

rack

• VM600 MPS rack (CPUM) security : Used to limit the functionality of a machinery protection system

(MPS) that is available via the system Ethernet connections of a

CPUM/IOCN card pair, helping to reduce the possibility of

interference in the machinery protection function of the rack itself

and/or in the machinery being monitored

• Event logging : VM600 system event and measurement event logging with up to

10000 of the most recent events stored on the CPUM (in nonvolatile memory).

Note: System event logs and measurement event logs are

downloaded from a CPUM using the VM600 MPSx software.

• Status indication : CPUM front-panel LEDs (front of VM600 rack) indicate the mode of

operation and status of the CPUM card

Communications interface

• VM600 rack (system)

communications

: Uses a VME communications link for communications with

MPC4/IOC4T and AMC8/IOC8T card pairs (via the VME bus on the

VM600 rack’s backplane).

Uses a system Ethernet connection for communications with a

computer running software such as VM600 MPSx.

• Fieldbus communications

(data gateway)

: Acts as a fieldbus server (slave) device that obtains data from

cards in the VM600 rack (that is, from MPC4/IOC4T and

AMC8/IOC8T card pairs) to share with fieldbus client (master)

devices such as a DCS or PLC:

• The CPUM can act as a Modbus server and use the fieldbus

interfaces to share data via Modbus RTU and/or Modbus TCP.

Note: The configuration of the fieldbus interfaces and the definition

of the data to be shared via fieldbus is defined by a Modbus

configuration file that is uploaded to the CPUM card using the

CPUM Configurator software.

Fieldbus interfaces

Number of channels : Multiple fieldbus interfaces (ports).

Ethernet and/or serial: Modbus and/or PROFINET.

Data transfer

• Modbus : Up to 131072 registers/words and 131072 coils/bits total.

That is, up to 2 × 65536 registers/words and 2 × 65536 coils/bits

(holding and discrete).

• PROFINET : Maximum slot size of 128 bytes.

Note: PROFINET is supported by later versions of the CPUM card

running firmware version 081 or later.

It was originally only supported by earlier versions of the CPUM card

running a special PROFINET version of firmware (version 801) that is

no longer supported.

Contact your local Meggitt representative or Meggitt SA for further

information.

CPU module (CPUM PC/104 slot 1)

Note: The CPU module is fitted to all versions of the CPUM card.

Module type : PFM-541I or equivalent

Processor type : AMD Geode™ LX800

Processor Speed : 500 MHz

Memory : 256 MB DRAM

Power supply to module (input) : 5 VDC, <1.8 A

Operating system : QNX

Communication interfaces – serial

Number : 2

Primary serial interface

• Network interface : RS-232

• Data transfer rate : Up to 115.2 kBaud

• Network topologies : Point-to-point

• Protocols : Meggitt TCP/IP proprietary protocol for communication with the

VM600 MPSx software

• Function : VM600 rack configuration and communications using the

VM600 MPSx software

• Connector : RS232 on CPUM card (see Connectors on page 10)

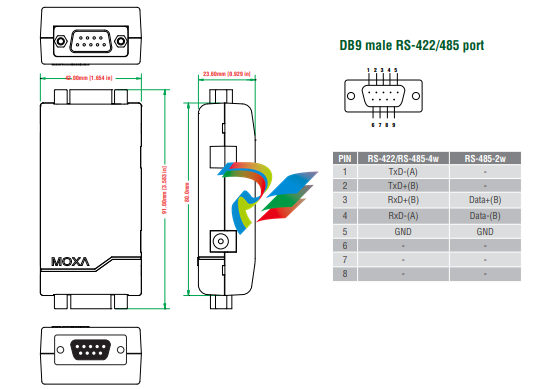

Secondary serial interface (requires IOCN card)

• Network interface : RS-232 or RS-485 (half-duplex (2-wire) or full-duplex (4-wire))

• Data transfer rate : Up to 115.2 kBaud

• Distance between devices : According to the relevant standard

• Network topologies : Point-to-point for RS-232 links.

Point-to-point or linear (daisy-chained) for RS-485 networks.

• Protocols : Modbus RTU

• Function : Fieldbus Modbus RTU communications

• Connector : RS on IOCN card (see Connectors on page 10)

• RS-485 (fieldbus) isolation : 500 VDC

S

SPECIFICATIONS (continued)

Communication interfaces – Ethernet

Number : 2

Primary Ethernet interface

• Network interface : 10/100BASE-TX – Ethernet / Fast Ethernet

• Data transfer rate : Up to 100 Mbps

• Distance between devices : Up to 100 m

• Protocols : Meggitt TCP/IP proprietary protocol for communication with the

VM600 MPSx software, Modbus TCP and/or PROFINET

• Function : VM600 rack configuration and communications using the

VM600 MPSx software, fieldbus Modbus TCP communications

and/or fieldbus PROFINET communications

• Connectors : NET on CPUM card or 1 on IOCN card (see Connectors on page 10)

Secondary Ethernet interface (requires IOCN card)

• Network interface : 10/100BASE-TX – Ethernet / Fast Ethernet

• Data transfer rate : Up to 10 Mbps

• Distance between devices : Up to 100 m

• Protocols : Modbus TCP

• Function : Fieldbus Modbus TCP communications

• Connector : 2 on IOCN card (see Connectors on page 10)

Serial communications module (CPUM PC/104 slot 2)

Note: The serial communications module is optional and is only fitted to the serial redundant version of the

CPUM card.

Module type : AIM104-COM4 or equivalent

Power supply to module (input) : 5 VDC, <220 mA

Isolation : >100 VDC

Communication interfaces – serial

Number : 2

Serial interfaces

• Network interface : RS-422 or RS-485 (half-duplex (2-wire) or full-duplex (4-wire))

• Data transfer rate : Up to 115.2 kBaud

• Distance between devices : According to the relevant standard

• Network topologies : Point-to-point for RS-232 links.

Point-to-point or linear (daisy-chained) for RS-422/ RS-485 networks.

• Protocols : Modbus RTU

• Function : Fieldbus Modbus RTU communications

• Connectors : A and B on IOCN card (see Connectors on page 10)

• RS-485 (fieldbus) isolation : 500 VDC

Notes

Jumpers on the CPUM and IOCN cards are used to configure the required operation of serial and Ethernet

interfaces and connectors. Refer to the VM600 machinery protection system (MPS) hardware manual for

further information.

System communications

Internal : VME bus interface (A24 / D16 master mode) for communication

with protection cards (MPC4 and AMC8) via VM600 rack

backplane

External : System communication interfaces (serial and Ethernet) for

communication with VM600 MPSx software running on an external

computer.

See Communication interfaces – serial on page 6 and

Communication interfaces – Ethernet on page 7.

External communication links/connections

• Connection to a computer/network : A serial communication interface (RS232 on CPUM card) can be

used for connections/communications between a CPUM/IOCN

card pair and a computer/network, using a standard serial cable.

See Communication interfaces – serial on page 6 and Connectors

on page 10.

An Ethernet communication interface (NET on CPUM card or 1 on

IOCN card) can be used for connections/communications

between a CPUM/IOCN card pair and a computer/network, using

standard cabling.

See Communication interfaces – Ethernet on page 7 and

Connectors on page 10.

• Connection to a fieldbus

(third-party system)

: A serial fieldbus communication interface (RS on IOCN card) can

be used for connections/communications between a CPUM/IOCN

card pair and serial-based fieldbuses (Modbus RTU).

See Communication interfaces – serial on page 6 and Connectors

on page 10.

An Ethernet fieldbus communication interface (NET on CPUM card

or 1 on IOCN card, or 2 on IOCN card) can be used for

connections/communications between a CPUM/IOCN

card pair and Ethernet-based fieldbuses (Modbus TCP).

See Communication interfaces – Ethernet on page 7 and

Connectors on page 10.

• VM600 MPSx software : Used for the configuration and operation of MPC4/IOC4T and

AMC8/IOC8T card pairs (using the CPUM/IOCN card pair as a

communications gateway)

• VibroSight® software : Used for the configuration of CPUM cards

Configuration

CPUM/IOCN card pair : Software configurable via Ethernet or serial, using a computer

running the VM600 MPSx and CPUM Configurator software.

Note: Serial (RS-232 / RS-422 / RS-485) line configuration and

Ethernet port to connector routing is determined by jumpers on the

CPUM and IOCN cards.

SPECIFICATIONS (continued)

Time synchronisation

Time reference for CPUM : Network time protocol (NTP) server or

CPUM’s internal real-time clock (RTC) with battery backup

Protocol used between VM600 cards

and host computer

: Network time protocol (NTP)

Note: When VM600 system event and/or measurement event logging is used, the time and date must be

configured for the CPUM in order for the timestamps in the event log files to be correct.

Environmental

Operating

• Temperature : −20 to 65°C (−4 to 149°F)

• Humidity : 0 to 90% relative humidity, non-condensing

Storage

• Temperature : −25 to 80°C (−13 to 176°F)

• Humidity : 0 to 90% relative humidity, non-condensing

Approvals

Conformity : CE marking, European Union (EU) declaration of conformity.

EAC marking, Eurasian Customs Union (EACU) certificate/

declaration of conformity.

Electromagnetic compatibility : TR CU 020/2011

Electrical safety : TR CU 004/2011

Environmental management : RoHS compliant

Russian federal agency for technical

regulation and metrology (Rosstandart)

: Pattern approval certificate CH.C.28.004.A N° 60224,

dated 11.11.2015

Power supply (to CPUM/IOCN)

Source : VM600 rack power supply

Voltage : 5 VDC

Power consumption

• CPUM : <10 W

• IOCN : <2 W

Total power consumption

(CPUM/IOCN card pair)

: ≤12 W

Control inputs (buttons)

CPUM

ALARM RESET : Used to reset all latched alarms (and associated relays) for all

protection cards in the VM600 rack (MPC4/IOC4T and AMC8/

IOC8T)

OUT+ and OUT− : Used to select a measurement channel for the currently selected

protection card (slot)

SLOT+ and SLOT− : Used to select a slot (protection card) in the VM600 rack

Note: OUT and SLOT button combinations are also used to enable

or disable VM600 rack (CPUM) security, that is, limit the VM600 MPSx

software to “read only” operations.

Status indicators (LEDs)

CPUM

DIAG : Green LED used to indicate the status of the CPUM card: off,

normal operation and status of VM600 MPS rack (CPUM) security

OK : Green LED used to indicate the status of the OK system check

(sensor OK link check) for the currently selected measurement

channel

A

(Alert)

: Yellow LED used to indicate the status of the alarm monitoring (Alert

or Alert−) for the currently selected measurement channel

D

(Danger)

: Red LED used to indicate the status of the alarm monitoring

(Danger or Danger−) for the currently selected measurement

channel

Note: In addition to the LED indicators, a front-panel display is fitted to all versions of the CPUM card.

Connectors

CPUM

• NET : 8P8C (RJ45), female.

Used for the primary Ethernet connection.

• RS232 : DE-9 (9-pin D-sub), female

Used for the primary serial connection.

IOCN

• RS : 6P6C (RJ12/RJ25), female.

Used for the secondary serial connection.

• A : Two 6P6C (RJ12/RJ25), female.

Used for additional serial connections (requires the optional serial

communications module).

• B : Two 6P6C (RJ12/RJ25), female.

Used for additional serial connections (requires the optional serial

communications module).

• 1 : 8P8C (RJ45), female.

Can be used for the primary Ethernet connection (instead of the

CPUM connector (NET)).

• 2 : 8P8C (RJ45), female.

Used for the secondary Ethernet connection.

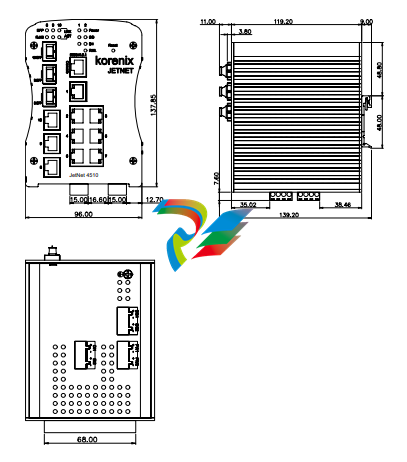

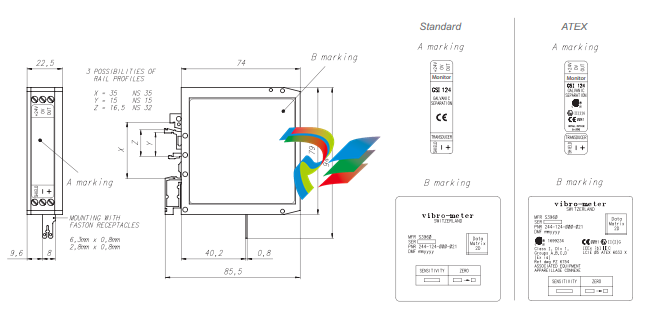

Physical

CPUM

• Height : 6U (262 mm, 10.3 in)

• Width : 40 mm (1.6 in)

• Depth : 187 mm (7.4 in)

• Weight : 0.40 kg (0.88 lb) approx.

IOCN

• Height : 6U (262 mm, 10.3 in)

• Width : 20 mm (0.8 in)

• Depth : 125 mm (4.9 in)

• Weight : 0.25 kg (0.55 lb) approx.

To order please specify

Type Designation Ordering number (PNR)

CPUM Different versions of the VM600 modular CPU card:

– Ethernet redundant

Modular CPU card with a CPU module that supports two

Ethernet interfaces and two serial interfaces.

This CPUM supports Ethernet interfaces on the front panel

(CPUM) and the rear panel (IOCN), a serial interface (RS-232)

on the front panel (CPUM) and a serial interface (isolated

RS-232/RS-485) on the rear panel (IOCN).

200-595-0Ss-33h

(601-003-000-VVV3610-1CC-CCC

when pre-configured See notes)

– Ethernet redundant varnished

Same as the (standard) Ethernet redundant version, with a

conformal coating for additional environmental protection.

200-595-0Ss-33hl

(601-003-000-VVV3V610-1CC-CCC

when pre-configured See notes)

– Serial redundant

Modular CPU card with a CPU module that supports two

Ethernet interfaces and two serial interfaces, and a serial

communications module that supports additional serial

interfaces.

This CPUM supports Ethernet interfaces on the front panel

(CPUM) and the rear panel (IOCN), a serial interface (RS-232)

on the front panel (CPUM) and a serial interface (isolated

RS-232/RS-485) on the rear panel (IOCN). It also supports two

additional serial interfaces

(RS-422/RS-485) on the rear panel (IOCN).

200-595-0Ss-53h

(601-003-000-VVV5610-1CC-CCC

when pre-configured See notes)

IOCN Different versions of the input/output card for the CPUM:

– Ethernet redundant 200-566-000-1Hh

– Ethernet redundant varnished

Same as the (standard) Ethernet redundant version, with a

conformal coating for additional environmental protection.

200-566-000-1HhL

Notes

Different versions of the CPUM card can be supplied pre-configured with different configurations, as denoted by the 9-digit code in

the ordering number (610-1CC-CCC).

“1CC-CCC” represents the different configurations that can be used by a finished product. For example, 610-100-000 corresponds

to the ‘standard’ configuration that is uploaded to a CPUM card (200-595-0Ss-HHh), if no other configuration is specified. For

information on other configurations. Contact your local Meggitt representative or Meggitt SA for further information.

“Ss” represents the firmware (embedded software) version and “Hh” the hardware version of a card. “S/H” increments for major

modifications that can affect product interchangeability and “s/h” increments for minor modifications that have no effect on

interchangeability.

“VVV” represents the different firmware (embedded software) versions and hardware versions that can be used by a

finished product.

RELATED PRODUCTS

ABE04x VM600 system racks : Refer to corresponding data sheet

CPUR and IOCR VM600 rack controller and communications

interface card pair

Note: With rack controller redundancy and

support for Modbus RTU/TCP

: Refer to corresponding data sheet

CPUR2 and IOCR2 VM600 rack controller and communications

interface card pair

Note: With mathematical processing of

fieldbus data and support for Modbus TCP

and PROFIBUS

: Refer to corresponding data sheet

AMC8 and IOC8T VM600 analog monitoring card and

input/output card

: Refer to corresponding data sheet

MPC4 and IOC4T VM600 machinery protection card and

input/output card

: Refer to corresponding data sheets

RLC16 VM600 relay card : Refer to corresponding data sheet

Meggitt (Meggitt PLC) is a leading international engineering company, headquartered in England, that designs and delivers high-performance

components and subsystems for aerospace, defence and selected energy markets. Meggitt comprises four customer-aligned divisions:

Airframe Systems, Engine Systems, Energy & Equipment and Services & Support.

The Energy & Equipment division includes the Energy Sensing and Controls product group that specialises in sensing and monitoring solutions for a

broad range of energy infrastructure, and control valves for industrial gas turbines, primarily for the Power Generation, Oil & Gas and Services markets.

Energy & Equipment is headquartered in Switzerland (Meggitt SA) and incorporates the Vibro-Meter® product line, which has over 65 years of sensor

and systems expertise and is trusted by original equipment manufacturers (OEMs) globally.

All information in this document, such as descriptions, specifications, drawings, recommendations and other statements, is believed to be

reliable and is stated in good faith as being approximately correct, but is not binding on Meggitt (Meggitt SA) unless expressly agreed in

writing. Before acquiring and/or using this product, you must evaluate it and determine if it is suitable for your intended application. You

should also check our website at www.meggittsensing.com/energy for any updates to data sheets, certificates, product drawings, user

manuals, service bulletins and/or other instructions affecting the product.

Unless otherwise expressly agreed in writing with Meggitt SA, you assume all risks and liability associated with use of the product. Any

recommendations and advice given without charge, whilst given in good faith, are not binding on Meggitt SA. Meggitt (Meggitt SA) takes

no responsibility for any statements related to the product which are not contained in a current Meggitt SA publication, nor for any

statements contained in extracts, summaries, translations or any other documents not authored and produced by Meggitt SA.

The certifications and warranties applicable to the products supplied by Meggitt SA are valid only for new products purchased directly from

Meggitt SA or from an authorised distributor of Meggitt SA.

In this publication, a dot (.) is used as the decimal separator and thousands are separated by thin spaces. Example: 12345.67890.

Copyright© 2019 Meggitt SA. All rights reserved. The information contained in this document is subject to change without prior notice