WATLOWCompact Loop System, Providing Powerful Control in a 1 /8 DIN Package

Watlow’s SERIES CLS200 is a powerful line of controllers,

combining performance and flexibility with compact design.

The 4, 8 and 16 loop versions provide complete controller

solutions for a broad range of applications. Support for

multiple types of sensor inputs is available, including

thermocouples, RTDs, linear voltage, current and frequency.

Each controller includes built-in serial communications

for computer interface and data acquisition. Optional

programmable ramp and soak features allow complex

batch processing and sequencing. An enhanced feature

option offers cascade control, ratio control, differential control,

process variable retransmit and remote analog set point.

The SERIES CLS200 controllers are UL® and C-UL® listed,

RoHS by design and meet the requirements of the European

Community EMC Directive and carry the CE mark.

Features and Benefits

PID control of up to 16 heat and cool loops

• Minimizes panel space per loop

• Reduces installation time

• Increases reliability: fewer parts means fewer failures

Auto-tune

• Requires less time tuning

• Achieves excellent control with less expertise

Menu-guided operation with full text display

• Allows quick setup of the controller

• Simplifies operation

Eight jobs stored and recalled

• Changes quickly from one process to another

Multiple and mixed inputs

• Accepts combinations of thermocouples, RTDs, linear dc

voltage and linear dc current sensors

• Reduces learning curve and inventory

Sensor failure detection

• Reduces time troubleshooting reversed, shorted and

open sensors

High/low process and deviation alarms for each input

• Integrates as needed with other automation controllers

34 digital outputs

• Provides flexible configuration

• Allows use of outputs as needed for control and alarms

EIA/TIA-232 and 485 communications

• Connects to software for easy operation

• Allows integration with controllers and software

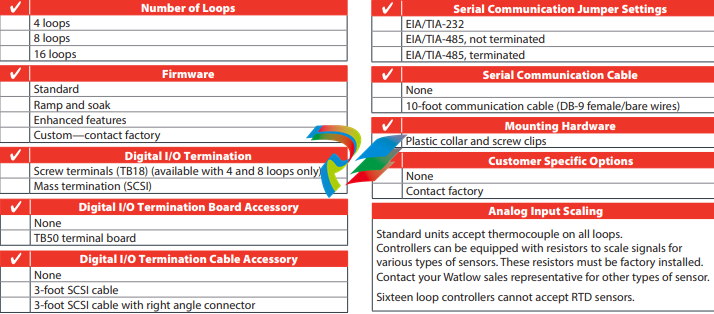

Firmware Options

Choose firmware with the features needed for the

application:

• Standard—includes closed-loop PID control, auto-tune,

alarms, job memory and failed sensor detection.

• Ramp and soak—includes the standard firmware

features with the addition of ramp and soak and process

variable retransmit. Each channel can be configured for

standard PID control or ramp and soak operation. Unused

control outputs on any channel can be configured to

retransmit a process value.

• Enhanced features— includes the standard firmware

features with the addition of process variable retransmit,

remote analog set point, cascade control, ratio control

and differential control algorithms. Each channel can be

configured for standard PID controller or one of the other

control algorithms. Each channel of cascade control or

remote analog set point requires two controller channels.

Unused control outputs on any channel can be

configured to retransmit a process value.

• Custom— application-specific, engineered solutions are

available. Contact your Watlow representative.

Digital Input/Output Options

Controllers with the mass termination option for digital

I/O termination have a 50-pin SCSI connector which allows

access to all digital inputs and outputs. SCSI cables and the

TB50 digital I/O termination board options are offered to

allow connection of field wiring.

Four and eight loop controllers can be configured with

screw terminal connections on the back for connecting

digital inputs and outputs, but this limits access to

15 outputs (10 of which can be used for control loops)

and three inputs.

Because the SERIES CLS200 has no onboard analog

outputs, applications that use process variable retransmit

typically require one SDAC module per retransmitted

signal.

DAC and SDAC Modules

The optional DAC and SDAC modules are available for

Watlow SERIES CLS200 controllers.

DAC

The DAC (digital to analog converter) converts one or two

of the controller’s distributed zero crossing (DZC) output

signals to analog signals. Each output is field configurable

for 4-20mVDC, 0-5VDC or 0-10VDC.

SDAC

The SDAC (serial digital to analog converter) converts

one controller output to a precise analog voltage or

current signal. The unit is typically used for process

variable retransmit, open-loop control, motor or belt speed

control, or phase-angle fired SCR power controllers. The

SDAC bears the CE mark and is UL® and C-UL® listed.

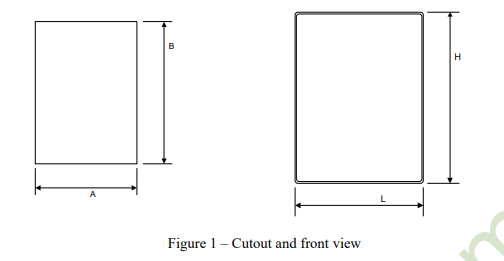

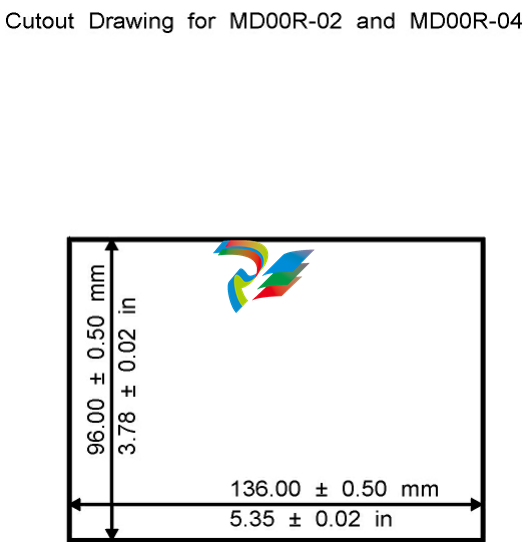

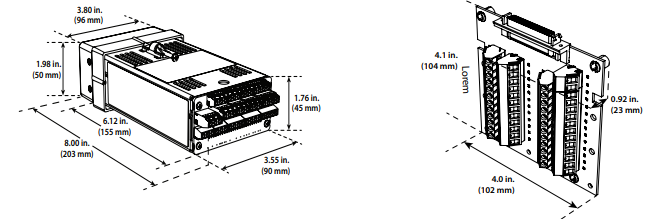

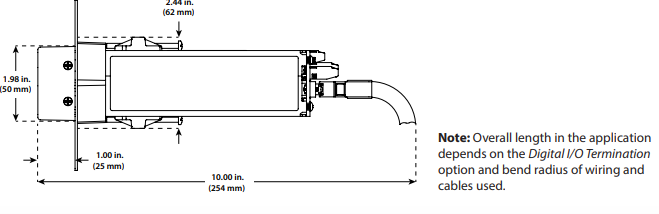

Dimensional Drawings

Figure 1 – TB18 Screw Terminals

Digital I/O Termination Option Shown

Figure 2 – TB50 Terminal Board Option

Figure 3 – Mass Termination (SCSI) Digital I/O Termination

and Cable Options

CLS200 Specifications

Operator Interface

• 32-character vacuum fluorescent display

• 8-key keypad to access guided menus and prompts,

enter passkey sequence, set values, switch between

single channel and multiple channel displays

• Controller configuration can be loaded via serial

communication

Analog Inputs

• 4-loop model: 4 differential inputs

• 8-loop model: 8 differential inputs

• 16-loop model: 16 single-ended inputs

Analog Over Voltage Protection

• ±20V referenced to digital ground

Maximum Common Mode Voltage

• 5V input to input or input to analog common

(4- and 8-loop models)

Common Mode Rejection (CMR)

• For inputs that do not exceed ±5V, >60dB dc to 1kHz and

120dB at selected line frequency

Noise Rejection

• 120dB at 60Hz

Sensors/Inputs

• Thermocouples: user-selectable type, direct connection,

linearization, reference junction compensation, reversed

and shorted thermocouple detection and upscale break

protection with output averaging

• RTD: (4 and 8 loop models only) 2- or 3-wire, platinum,

100Ω @ 0°C, DIN 0.003850Ω/Ω/°C curve, user-selectable

range. Two ranges offer different resolutions. Requires

scaling resistors. See ordering information.

• Linear: current and voltage signals from linear transmitters

• Pulse input

Input Range and Accuracy

Sensor Range (°C) Range (°F) Accuracy

Type B 66 to 1760°C 150 to 3200°F ±4.0°C

Type E -200 to 787°C -328 to 1448°F ±1.0°C

Type J -212 to 760°C -350 to 1400°F ±1.2°C

Type K -268 to 1371°C -450 to 2500°F ±1.3°C

Type R -18 to 1766°C 0 to 3210°F ±2.8°C

Type S -18 to 1760°C 0 to 3200°F ±2.8°C

Type T -268 to 399°C -450 to 750°F ±1.6°C

RTDs available on CLS204 and CLS208 only.

Sensor Range (°C) Range (°F) Accuracy

RTD1 -100 to 275˚C -148 to 527˚F ±1.1˚C

RTD2 -120 to 840˚C -184 to 1544˚F ±1.6˚C

Note: Accuracy @ 25˚C ambient. Valid for 10 to 100 percent

of span except Type B, which is specified for 800˚F to

3200˚F. RTD.

Linear Voltage and Current Inputs

Requires scaling resistors. See ordering information.

0-20mAVDC/4-20mAVDC

0-5VDC

0-10VDC

Temperature coefficient: 40ppm/°C

Other ranges available. Contact factory.

Pulse Input

• One TTL-level square wave input up to 2kHz

Input Sampling Rate at 60Hz

Each channel has the following scans per second:

• 4-loop model: 6 samples per second,

(update time: 0.167 sec.)

• 8-loop model: 3 samples per second,

(update time: 0.333 sec.)

• 16-loop model: 1.5 samples per second,

(update time: 0.667 sec.)

Internal Measurement Resolution

• 0.006 percent, greater than 14 bits

Calibration

• Automatic zero and full scale

Digital Inputs

• TTL-level used for selecting recipes or jobs, or R/S triggers

• 8 digital inputs and 1 pulse input with mass termination

(SCSI) digital I/O termination and TB50 terminal board

options

• 2 digital inputs and 1 pulse input with screw terminal

(TB18) digital I/O termination option

Digital Outputs

• 34 digital outputs with mass termination (SCSI) digital I/O

termination and TB50 terminal board options

• 11 control and alarm outputs with screw terminal (TB18)

digital I/O termination option

• 1 or 2 control outputs are user assigned for each loop

• Each control output can be configured for on-off time

proportioning, or distributed zero crossing

• Outputs sink up to 60mA each at 5VDC

• 350mA at 5VDC available from on-board supply

Alarm Outputs

• Independent process and deviation alarms for each

channel

• Alarms can operate any output not used for control

• User-programmable deadband, delay and startup

suppression

• Global alarm output activates when any alarm occurs

• Watchdog output indicates controller is functioning

correctly

Serial Interface

• EIA/TIA-232 or EIA/TIA-485

Baud Rate

• 2400, 9600 or 19200, user-selectable

Communications Protocols

• Form of ANSI X3.28-1976, (D1, F1) compatible with

Allen-Bradley PLC/2

• Modbus® RTU

Line Voltage/Power

• 15 to 24VDC ± 3VDC @ 1A (maximum),

300mA (no load)

Agency Approvals

• UL®, C-UL® listed: UL®61010-1 safety requirements for

measurement, control and laboratory equipment

• CE Mark: See Declaration of Conformity for details

• RoHS by design

Ordering Information

Instructions: Choose one option for each feature

Note: To obtain a part number for your choice of options, communicate your selections to your Watlow sales representative who

will provide a part number to you.