Product description

The AC / DC sensitive residual current monitor RCMA475LY is designed for monitoring earthed

power supply systems (TN and TT systems) where DC fault currents or residual currents continuously greater than zero may occur. These are in particular loads containing six-pulse

rectifiers or one way rectifiers with smoothing, such as converters, battery chargers, construction site equipment with frequency-controlled drives.

The prewarning stage (50 % of the set response value IΔn1) allow to distinguish between

prewarning and alarm. Since the values are measured with measuring current transformers,

the device is nearly independent of the load current and the nominal voltage of the system.

Application

• AC / DC sensitive residual current monitoring in earthed two, three or four conductor

systems.

• AC / DC sensitive current monitoring of single conductors de-energized under normal

conditions (e. g. N and PE conductors).

• Variable-speed drives

• Uninterruptible power supply systems (UPS)

Device features

• Internal measuring current transformer

ø 18 mm

• Two response values:

Alarm IΔn1: 30 mA…500 mA (0…700 Hz)

Prewarning IΔn2: 50 % / 100 % of IΔn1

• Adjustable response delay 0…10 s

(prewarning 0 / 1 s)

• Two separately adjustable alarm relays

with one changeover contact each

• N / O or N / C operation

• Fault memory

• Combined TEST and RESET button

• Connection external TEST and RESET

button

• LED bar graph indicator IΔn 0…100 %

• Connection external measuring instrument IΔn 0…100 %

• Sealable transparent cover

• Separate supply voltage

• Type B acc. to IEC 60755

Function

Residual current monitoring takes place via an internal measuring current transformer. When

the current respectively the residual current exceeds the set response value, the alarm LED

lights and the associated alarm relay switches when the set response delay has elapsed.

The alarm messages are stored. The fault memory can be reset by pressing the RESET button.

The device function can be tested using the TEST button.

The currently measured value in per cent related to the set response value is indicated on

the LED bar graph indicator.

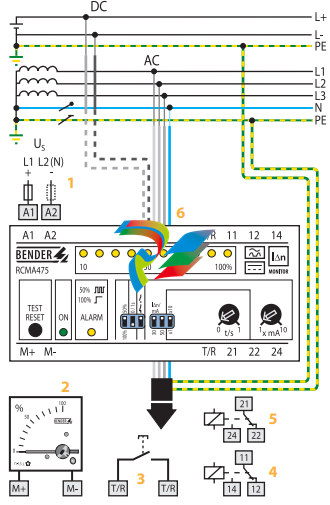

Wiring diagram – system connection, external connections

1 – Supply voltage US (see ordering information), a 6 A fuse recommended for line protection

2 – External measuring instrument

3 – External TEST and RESET button

4 – Alarm relay (alarm): switches when the fault current exceeds

the response value IΔn1.

5 – Alarm relay (prewarning): switches when the fault current

exceeds 50 % or 100 % of the response value IΔn1.

6 – Internal measuring current transformer

Do not route the PE conductor through the measuring current

transformer !

1 – Supply voltage US (see ordering information), a 6 A fuse recommended for line protection

2 – External measuring instrument

3 – External TEST and RESET button

4 – Alarm relay (alarm): switches when the fault current exceeds

the response value IΔn1.

5 – Alarm relay (prewarning): switches when the fault current

exceeds 50 % or 100 % of the response value IΔn1.

6 – Internal measuring current transformer

Do not route the PE conductor through the measuring current

transformer !

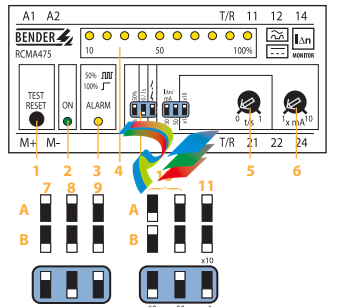

1 – Combined TEST and RESET button: short-time pressing (< 1 s)

= RESET, long-time pressing (> 2 s) = TEST.

2 – Power On LED: lights when the device is in operation and flashes

when the measuring range is exceeded.

3 – Alarm LED: lights when the fault current exceeds the set response value and flashes when 50 % of the set response value

are reached.

4 – LED bar graph indicator, shows the measuring value in per

cent related to the preset response value.

5 – Potentiometer for setting the response delay (0…1 s)

6 – Potentiometer for setting the response value (x 1…10 mA)

Setting of the DIP switches (white = switch position)

7 – Contact 21-22-24 (prewarning)

A – at 50 % of IΔn1

B – at 100 % of IΔn1

8 – Response delay prewarning

A – Delay 1 s

B – Delay 0 s

9 – Alarm relay

A – N / O operation

B – N / C operation

10 – Response range

A – 30 mA x 1…10 B – 50 mA

11 – Response delay

A – Setting value t

/s x10

B – Setting value t

/s x1

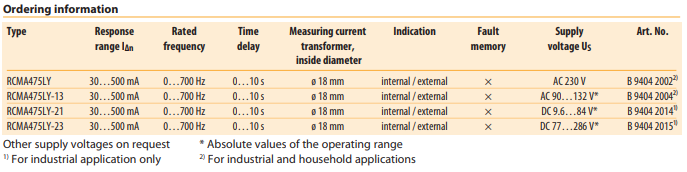

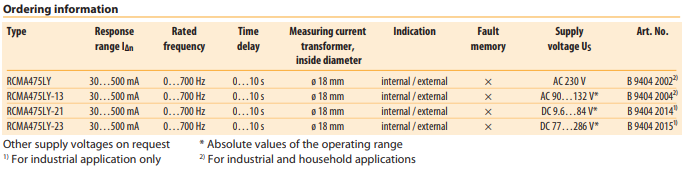

Technical data residual current monitor RCMA475LY

Insulation coordination acc. to IEC 60664-1

Rated insulation voltage AC 250 V

Rated impulse voltage / pollution degree 4 kV / 3

Voltage ranges

Supply voltage US see ordering information

Operating range of US 0.85…1.1 x US

Frequency range of US DC / 50…60 Hz

Power consumption ≤ 3.5 VA

Measuring circuit/response values

Internal measuring current transformer ø 18 mm

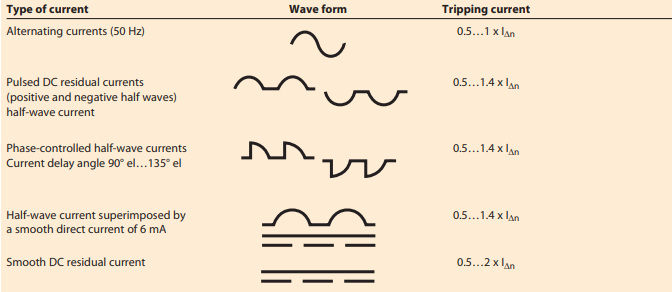

Operating characteristic acc. to IEC 60755 Type B

Rated residual operating current IΔn2 (prewarning) 50 / 100 % of IΔn1

Response delay tv 0 / 1 s

Rated residual operating current IΔn1 (alarm) 30…500 mA

Response delay tv, adjustable 0…10 s

Rated frequency 0…700 Hz

Relative percentage error 0…- 25 %

Hysteresis approx. 25 % of the response value

Response time tan at IΔn1 = 1 x IΔn1 / 2 (tv = 0 s) < 70 ms

Response time tan at IΔn1 = 5 x IΔn1 / 2 (tv = 0 s) < 40 ms

Displays

LED bar graph indicator 0…100 %

LEDs Power On, prewarning, alarm

Inputs / outputs

TEST and RESET button internal / external

Cable length external TEST and RESET button ≤ 10 m

Current source for external measuring instrument 0…100 % DC 0…400 μA

Load ≤ 12.5 kΩ

Switching elements

Number of switching elements 2 x 1 changeover contact

Operating principle, adjustable N / C operation / N / O operation

Electrical endurance, number of cycles 12000

Rated contact voltage AC 250 V / DC 300 V

Limited making capacity AC / DC 5 A

Breaking capacity 2 A, AC 230 V, cos phi = 0,4

0.2 A, DC 220 V, L / R = 0.04 s

Fault memory ON

General data

EMC immunity acc. to EN 61543

EMC emission acc. to EN 61000-6-4

Shock resistance IEC 60068-2-27 (during operation) 15 g / 11 ms

Bumping IEC 60068-2-29 (during transport) 40 g / 6 ms

Vibration resistance IEC 60068-2-6 (during operation) 1 g / 10…150 Hz

Vibration resistance IEC 60068-2-6 (during transport) 2 g / 10…150 Hz

Ambient temperature, during operation – 25 °C…+ 70 °C

Ambient temperature, when stored – 40 °C…+ 75 °C

Climatic category IEC 60721-3-3 3K5

Operating mode continuous operation

Mounting any position

Connection screw terminals

Connection properties

rigid / flexible 0.2…4 / 0.2…2.5 mm2

flexible with ferrules without / with plastic collar 0.25…2.5 mm2

Conductor sizes (AWG) 24…12

Protection class, internal components (IEC 60529) IP30

Protection class, terminals (IEC 60529) IP20

Type of enclosure X475

Enclosure material polycarbonate

Screw mounting 2 x M4

DIN rail mounting acc. to IEC 60715

Flammability class UL94V-0

Standards IEC 62020

Instruction leaflet BP404001

Weight ≤ 350 g

Accessories

Conditions of operation according to IEC 62020, IEC 60755 amendment 2, Type B

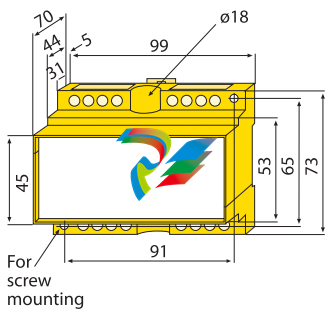

Dimension diagram X475

Dimensions in mm

Leave a comment

Your email address will not be published. Required fields are marked *