Our business is protecting yours

Power Generation, oil and gas production and distribution, petrochemical processing, gas turbine marine

propulsion — these are typical areas where high-value,

critical rotating machinery is employed.

Safety has always been a major issue and protection

systems, including vibration parameters, are frequently

mandatory.

As the need to provide continuously increasing value to

owners and shareholders grows more imperative, so

pressure is increasing on operators to reduce the cost of

running and maintaining their machinery.

DYMACTM* offers total system integration by bringing

advanced condition monitoring and protection systems

into a plant-wide control platform. This integration leads

to the avoidance of costly unexpected down-time and

reduced operating and maintenance costs.

The end result is not only improved profitability, but also

a better and safer environment.

Main features and benefits

Traditionally, separate systems have been provided for

machinery protection, on-line condition monitoring, and

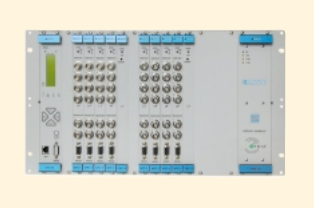

machinery performance assessment. However, the VM600

Series uses the latest digital signal processing technology

— and industry standard communications interfaces — to

deliver the most up-to-date, integrated, modular, scaleable

solution to all machinery protection, condition and performance monitoring requirements, within a single system

framework. Only two types of signal processing modules

are required — one for protection and one for condition

and performance monitoring data acquisition. Each card

can perform all of the necessary signal processing tasks,

with input from any appropriate sensor, simplifying

specification, installation, training and spares holding.

¥ All monitoring functions (absolute and/or relative

vibration, dynamic pressure, displacement, orbit, Smax,

position, expansion, etc.) available on a single card

¥ Communications over Ethernet or serial links using

standard protocols

¥ Remote configuration, interrogation and support

¥ Local display of levels and status

¥ Protection functions independent of condition

monitoring functions

¥ API-670 compliant

¥ Comprehensive voting logic combinations

¥ Cards are hot-swappable

¥ Dual redundant power supplies and communication

links

¥ One 6U rack accommodates up to 48 protection

channels or 192 condition monitoring/process inputs.

¥ “Platform independent” software –WindowsTM NT/2000,

SCO Open Server (UNIX), Linux

DYMAC total system capability

SENSORS & SIGNAL CONDITIONING

A full range of industrial accelerometers, velocity transducers, eddy current probes, dynamic pressure sensors, air gap

sensors, and ice detectors for high temperatures and other harsh environments.

MACHINERY PROTECTION SYSTEMS

Fully autonomous protection systems for instant detection of machinery problems. Protection for both excessive

vibration and over-speed conditions. A single universal card accepts input from all dynamic and static sensors, and

provides a comprehensive array of processing and voting logic, with analogue, DC and digital outputs to other systems.

MACHINERY CONDITION MONITORING

On-line and off-line hardware and software solutions for prediction of machinery problems in advance. Automatic highspeed detection of run-up/ coast-down and ’upset capture’ data, 16 channel parallel data acquisition cards, all dynamic

and static inputs. Sophisticated Condition Monitoring software for machinery monitoring and analysis, including

continuous streaming technology, logging by exception, interfaces to portable devices and DCS systems, and a full array

of diagnostic tools such as Fast Fourier Transform (FFT). Remote access over modem, network or internet. Specialised

applications including hydro turbines and reciprocating compressors.

MACHINERY PERFORMANCE MONITORING

Basic Package — manual or automatic data entry, simple performance calculations and trending of aero thermal

parameters.

Advanced package — automatic data entry, modelling refined with experience, comparison of actual against expected

performance giving a true online picture of machinery behaviour for decision support.

Maintenance Optimisation — fuel used, emissions, calculation of emission taxes, parts life calculation for hot components, predicted and measured calculation for maintenance actions.

SERVICE AND SUPPORT

Help and advice from trained and qualified staff are available across the globe through the DYMAC network. Service

may range from simple instrument installation support, through to training (on-site or at a DYMAC facility); up to

results-based machinery maintenance contracts involving SKF Reliability Systems.

With more than 35 years experience in production and service of

instruments for monitoring, analysis and diagnosis of mechanical

behaviour of critical machinery, DYMAC’s commitment is to

provide the optimum combination of product, people and skills to

ensure that machinery health monitoring is an added value

component of the customer’s business.

To optimize this, a strategic alliance between DYMAC and

Vibro-Meter’s Industrial & Marine division was formed.

Combining the offering of the two groups into one comprehensive

range of machinery management solutions and services, customers

will experience a responsive and flexible approach in meeting

their monitoring and protection needs, together with the best

possible customer support.

Vibro-Meter continues its relationships with major machinery

manufacturers and packagers by concentrating on OEM accounts.

DYMAC, known for tailored solutions to end-users in many

industries and for comprehensive local support, concentrates on

end-user applications.

Vibro-Meter SA is a member company of Meggitt PLC, an international group engaged in the design and manufacture of high

integrity products for Aerospace, Electronics and Industrial

Controls markets worldwide.

DYMAC is part of the Reliability Systems unit of the worldwide

AB SKF Group. Combining nearly 100 years of bearing and

industry knowledge, SKF Reliability Systems offers technology

product and service solutions designed to increase plant efficiency

and profitability

Leave a comment

Your email address will not be published. Required fields are marked *