Why monitor your machinery ?

Monitoring is fundamental to Plant Asset Management.

Whether your business is in the power generation, oil

and gas or petrochemical industry, understanding the

mechanical behaviour of rotating machinery brings you

the following benefits:

Safety

Monitoring systems help avoid catastrophic failures

and unplanned outages, protecting your personnel and

your investment.

Return on assets

The financial return delivered by your physical assets

is increased. Monitoring systems help you maximize

the overall productivity of your turbomachinery

through:

• Higher availability (reduced outages,

maintenance optimization)

• Improved machine efficiency

• Lower spare parts inventory and maintenance costs

Emissions and environment

Our performance and emissions monitoring functions

help to reduce fuel consumption as well as CO2 and

NOX emissions, in order to comply with environmental

regulations.

Why choose VM600

integrated solution ?

One single expandable platform

Vibro-Meter’s VM600 platform truly integrates all protection,

condition and performance monitoring functions in a single

system. It is easily expandable and does not require

additional internal wiring.

One module does all

We are pioneers with our solution based on single modules

processing all parameters (vibration, velocity, displacement,

dynamic pressure, temperature, etc…) used for protection

and condition monitoring.

When you need a new function, it is already included in the

module in your system.

High reliability

All modules are independent and separately protected; they allow continuous system operation

if one has to be replaced. The VM600 has dual, crossed redundancy between power modules

and mains lines, allowing true power supply redundancy.

One source

Request a complete solution from Vibro-Meter! In our Fribourg headquarters (Switzerland),

more than 550 employees combine their expertise and commitment to designing and building

all parts of your system: Sensors for harsh environments (measuring vibration, dynamic

pressure, displacement…), high performance monitoring systems and software. Our sales and

support network delivers outstanding service worldwide.

CMS software

Machinery protection is an absolute must, as the

failure of high capital machinery results in critical

safety issues and significant financial losses. The

VM600 provides on-line protection of vibration, speed,

displacement, temperature, dynamic pressure in GT

combustors and many other machine parameters.

MPS (Machinery Protection System) software has an

easy-to-use graphical user interface for the

protection of critical rotating machinery. It allows

stand-alone hardware configuration and data display

through a serial connection to the VM600.

MPS1 & MPS2 softwares are used for the VM600

configuration (installed modules) and the

programming of functions.

Additionally, the MPS2 tool allows real-time values

(bar graphs and strip charts), trend charts and longterm (data average) charts to be displayed.

Condition-based maintenance is a predictive

methodology that is used to improve your

machinery’s safety, availability and efficiency.

Vibro-Meter’s CMS (Condition Monitoring System)

software is dedicated to the support of operators

and engineers, enabling them to rapidly identify a

problem, evaluate a situation and determine

appropriate actions to take.

CMS software has a truly modular architecture

that comprises of several Monitoring Modules. It

runs under Windows, uses an SQL database and

can be remotely accessed through the web.

For further applications, CMS software provides a

suite of standard Communication Interfaces,

enabling data transfer to/from any third-party

system. Users benefit from the full flexibility and

scalability of the CMS system, because it enables

the correlation of vibration data with other

process parameters.

All rotating machines

• Absolute vibration

• Relative shaft vibration (x,y)

• Absolute shaft vibration +

• Shaft position, displacement

• Displacement (valves, gates, cylinders)

• Static (oil) pressure

• Temperature

• Speed

Gas turbines

• Dynamic (combustor) pressure

Hydro turbines

• Airgap

Steam turbines

• Shaft eccentricity (x,y)

• Absolute expansion

• Differential expansion

• Casing expansion

Example: Gas turbine

Monitoring Modules

• Administrator – Access to all CMS modules

• Configuration Editor – Hardware parameters definition

• Mimic – Machine and data display

• Data Analyser – Data handling & display

• Event Viewer – Recorded events, limit values reached

• Rule Box – Execute actions according to machine conditions

• Air Gap – Hydro generator’s air gap monitoring

• Alert Performance – Operation optimization, fleet management,

emissions monitoring

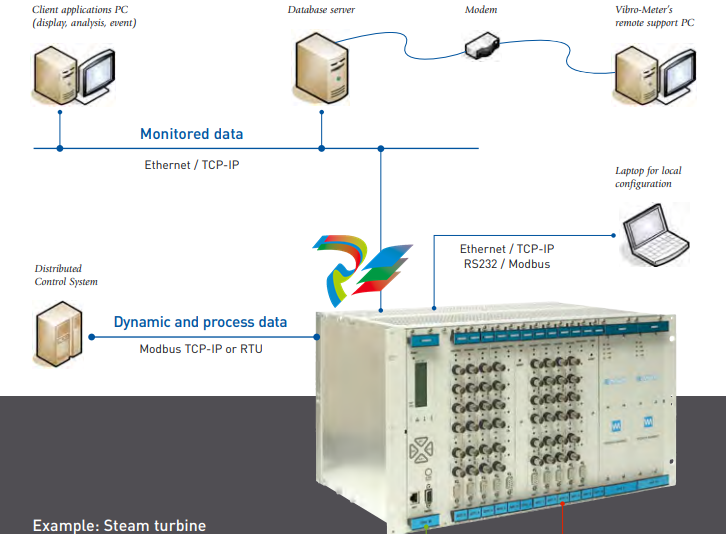

VM600 Networking

VM600 can be operated as a stand-alone unit configured from a laptop PC or can be networked and integrated

with other control and information systems using “industry standard” protocols. Configuration and display can

be provided by an “applications PC” running Windows operating system

Our expertise

Engineering

Vibro-Meter has a core team of skilled design engineers with vast

experience in designing complex electronics for high precision

measurement applications. High quality analogue signal

acquisition circuitry is integrated with data handling, digital signal

processing and communication circuitry.

We also have a complete in-house capability to test and qualify

state-of-the-art monitoring systems. We are able to simulate

complete machinery applications in our labs, to meet the latest

industry requirements.

To guarantee the uniqueness of our technology and know-how,

we continuously invest in training, technical innovation and first

class simulation and design software. To support our continuous

innovative effort, we have ongoing collaborations with several

renowned universities and industrial partners.

Manufacturing

Since the 80’s Vibro-Meter has had a Production Planning

System, enabling high quality and productivity objectives to be

achieved.

Our large and modern manufacturing facility in Fribourg

(Switzerland) is designed to ensure the highest quality standards

and organized to efficiently produce large scale orders as well as

small batches.

Skilled and experienced production staff can manufacture a

series of products adapted to fulfil the special requirements of

our customers.

Qualification & quality insurance

The quality and reliability of Vibro-Meter’s products has been

widely recognized since our entry into the aviation sector in the

70’s. This is when our Quality System was put in place. Our latest

BS EN ISO9001:2000 certification was awarded in April 2007.

Our continuous improvement culture applies to everything we

undertake. All employees strive to consistently develop, maintain

and improve our quality management system at every

opportunity. Customers are the focus of everything we do.

Case studies

Siemens uses Vibro-Meter’s VM600 to protect and

remotely monitor the world’s most powerful gas

turbine (GT).

“Irsching 4” near Ingolstadt (Germany) is the test

power plant for the new SGT5-8000H, which is the

world’s most powerful GT with a 340MW simple cycle

power output. The GT was first fired in December

2007. After an 18-month trial operation period, it will

be expanded to become a 530 MW combined cycle

power plant (CCPP) and will be handed-over by

Siemens to E.ON for commercial operation in 2011.

This technologically leading CCPP will achieve an

efficiency of 60%, which is a new world record. As a

result, it will emit approximately 40000 tons of CO2

per year less than comparable existing plants.

Monitoring vibrations and GT’s combustion is a proven

way to contribute to reliable GT operation, with the

target of reaching the highest possible efficiency and

lower emissions. Siemens has chosen Vibro-Meter to

provide the monitoring system for the SGT5-8000H.

Our integrated solution includes dynamic pressure

sensors (CP), as well as relative and absolute

vibration sensors (CA and TQ) and a VM600 protection

& condition monitoring system.

All data collected by the VM600 are continuously

transferred to Siemens’ Intranet, interfaced with their

Win_TS system (a global networked plant diagnostic

platform). With these tools, experts working in

Siemens’ Diagnostic Centres (Erlangen and Orlando)

and Research-and-Engineering Centres (Erlangen,

Berlin, Muelheim, Orlando and others) can for

example remotely calculate balancing for turbines

located in plants all over the world. Using this

information, staff on-site can balance a turbine

without the need for an on-site visit by experts, saving

time and cost.

Vibro-Meter is proud to contribute to Siemens’

leading-edge technology and their outstanding

support to customers.

Hydro turbine-generator: “Shipshaw” Hydro Power Plant (Canada)

Remote condition monitoring (VM600 system, with LS and CA sensors)

Heavy duty gas turbine: “Nhon Trach” combined cycle power plant (Vietnam)

Protection and condition monitoring (VM600 system, with CP, CA and TQ sensors)

Shipshaw Hydro Power Plant (HPP) is owned by the

largest independent producer of hydroelectricity in

Quebec, Rio Tinto Alcan. At the time of construction, the

power plant was the most powerful in the world, with an

output of 896 MW from 12 generators.

Condition monitoring of hydroelectric generators is

critically important to increase efficiency, plan

preventive maintenance and detect wearing of critical

parts.

In Shipshaw HPP, the main control centre is 60 km away

from the plant. The customer’s goal is to ensure

permanent remote monitoring and analysis by their

experts. This reduces on-site human presence and thus

lowers maintenance costs. High speed network access

via optical fibre is established between the control

centre and Vibro-Meters’ VM600 systems in the plant.

Twelve VM600 Systems provide condition monitoring of

vibration and other dynamic measurements (e.g. relative

vibration, axial position, rotating speed, dynamic

pressure and generator’s air gap). Temperatures and

plant process signals are also monitored (e.g. active

power, oil bearings temp., stators temp., ambient temp.,

oil levels, water flow, as well as other flows and plant

data). Furthermore, Vibro-Meter provides air gap

measuring systems for the generator and vibration

measurement chains to monitor bearing vibration in

both generators and turbines.

Alstom uses Vibro-Meter’s VM600 for the first time to

protect and monitor a GT13E2 for a large CCPP in Vietnam.

The Nhon Trach CCPP project will be carried out in

two phases, with the GT operating first in simple cycle

to support the high energy demand during the dry

season in 2008. In the second phase, further

equipment will be added for a full combined cycle

operation. Once fully operational, the 460MW CCPP

will be capable of supplying 2.5 billion KWh annually

to the national grid.

With more than one hundred GT13E2s in operation

and millions of fired hours to its credit, Alstom’s

180MW gas turbine has already built an impressive

track record of reliability and performance. The

VM600 monitoring system and high sensitivity

piezoelectric accelerometers supplied by Vibro-Meter

alerts the operator in case of abnormal bearing

vibrations, allowing early maintenance planning.

A challenge with heavy duty GTs is to combine the

highest possible efficiency with extremely low NOx

emissions. Vibro-Meter’s dynamic pressure sensors

allow Alstom to control combustion parameters such

as fuel injection.This leads to very low emissions,

reduced fuel consumption and long intervals between

major inspections.

Vibro-Meter is proud to contribute to Alstom’s

success in providing customers using their GT13E2

with high efficiency, operational flexibility and longer

inspection intervals, leading to lower maintenance cost

Since its foundation in 1952, Vibro-Meter in Fribourg

(Switzerland) has been supplying reliable, high

quality instrumentation for aviation and industrial

customers worldwide. Vibro-Meter has been part of

the Meggitt group since 1998. With its headquarters

in the United Kingdom, Meggitt PLC is an

international group of companies specialising in

aerospace equipment, high performance sensing

systems and defence.

Vibro-Meter

’s quality policy is fundamental to its

success. The excellent reputation of our company is

built on our dedication to fulfil our customers

’

needs, our continuous investment in technical

innovation and the skills and experience of our staff.

We develop and supply engine monitoring units for

new airliners produced by all leading aircraft

manufacturers. For more than 30 years, our

aerospace division has been the leading supplier of

vibration and pressure monitoring systems for

aircraft engines.

The power generation industry widely uses the

complete monitoring solutions for turbomachinery

offered by our industrial and marine division. Our

integrated systems are adopted by major

manufacturers of gas turbines, steam turbines and

water turbines.

Our international network of subsidiaries and

distributors delivers outstanding support worldwide,

for both our aerospace and power industry

customers.

Leave a comment

Your email address will not be published. Required fields are marked *