VM600 First-Generation:

One module does it all

When vibro-meter introduced

the VM600 architecture in 2000,

it represented a dramatic leap

forward that sent shockwaves

through the industry with numerous

innovative features.

The most notable of these was

the simplicity of an architecture

that used a single card type – the

MPC4 – to address all channel

types except temperature. Prior

architectures, and the prevailing

model embraced by every other

leading manufacturer of the time,

was a reliance on a large diversity

of module types. For example, one

well-known manufacturer required

more than 20 different module

types in their system to achieve

the full complement of all available

functionality.

Compounding the issue, each

monitor module type had as many

as 3 different corresponding I/O

module variations. The spare

parts implications were significant

– along with the widely varying

costs of each module depending

on the channel types supported.

It was a complex architecture with

a complex diversity of modules, a

complex pricing structure, and a

complex spare parts burden.

In contrast, the VM600 required

only 4 basic card types (power,

communications, temperature, and

universally configurable vibration)

for comprehensive machinery

protection, each with only a single

type of corresponding I/O module.

In a word, the system was uniquely

simple – without sacrificing

functionality. It also introduced

the concept of combining speed

/ phase reference measurements

on a single module as auxiliary

channels.

This allowed four channels of

vibration and two channels of

tachometer and/or phase reference

to be addressed in a single rack

slot via the MPC4 (Machine

Protection Card – 4 channel).

In fact, it perhaps would have been

better named “MPC4+2” for this

very reason

.

In addition, 4 relays were included

on each MPC4, turning a single

module into a fully self-contained

monitor with all required protective

functions. Hence, the slogan “one

module does it all” aptly described

the workhorse of the system: the

MPC4 module that provided true

“universal” programmability for all

required vibration channel types

and sensors.

The VM600 was introduced in

2000 and required only 4 basic

module types for comprehensive

machinery protection functionality:

power, temperature, vibration, and

communications.

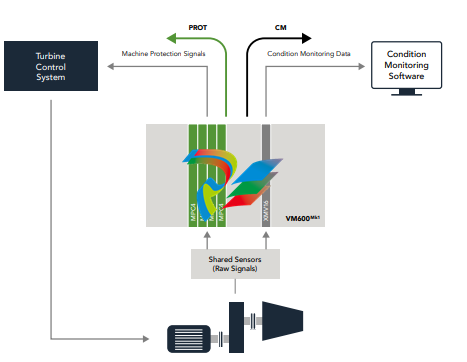

Segregated condition monitoring

Another key innovation of the

first-generation architecture was

entirely segregated, 16-channel

condition monitoring (CM)

modules that ensured machinery

protective functions could never

be compromised by failures in the

condition monitoring hardware,

yet resided in the same rack

chassis and could share input

signals with the MPC4 protective

modules – or use entirely separate

inputs if desired. Two CM module

types were available – one for

vibration (XMV16) and one for

gas turbine combustion dynamics

(XMC16). Other manufacturer’s

platforms of the era used highly

integrated condition monitoring

that co-mingled protective and

CM functions, resulting in a level

of integration that amplified rather

than attenuated vulnerabilities.

The VM600’s first-generation

architecture physically separated

condition monitoring from

protection by using separate

modules – the MPC4Mk1 for

protection and the XMV16 for

condition monitoring. A variant

of the XMV16 (the XMC16) was

used for combustion dynamics

monitoring on low-NOx gas

turbines.

As gas turbine firing temperatures

increased in the 70s, 80s, and 90s

to achieve greater efficiencies,

these efficiencies came at the

expense of increased NOx

emissions. It was not long before

environmental concerns demanded

these increased NOx emissions

be reduced, and new combustor

technology emerged as a result,

referred to as Dry Low NOx

(DLN) or Dry Low Emissions (DLE)

designs1

.

Although these designs did indeed

reduce NOx emissions, they

entailed so-called “metastable”

combustion conditions that could

impose extremely damaging

dynamic pressure pulsation forces

on the combustor2

. If not very

carefully monitored and controlled,

combustor life could be severely

degraded.

It was out of this fundamental

need that gas turbine combustor

monitoring emerged.

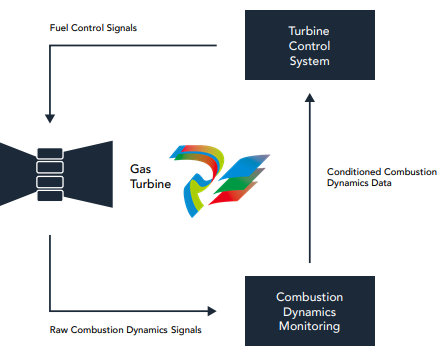

The concept is quite simple: adjust

the fuel/air mixture to be as lean

as possible, but not so lean as

to introduce an unstable flame

and the accompanying dynamic

pressure pulsations that will

prematurely age (or destroy) the

combustor.

Using highly specialized hightemperature pressure sensors, the

pressure inside each combustor

is monitored for the presence of

these damaging pulsations and the

fuel/air ratio is continually adjusted

using a closed feedback loop

between the dynamic pressure

sensing system and the turbine

control system where the fuel/air

mixture is adjusted.

When pulsations are detected,

the flame is unstable and the

mixture is too lean. The ratio is

then adjusted (less lean) such that

the combustor is perpetually on

the verge of instability, but without

actually pulsating. In other words,

a precisely controlled balancing act

to maintain that tiny operational

zone existing between stable and

unstable combustion – a zone

where efficiency is highest and

NOx emissions lowest.

It turns out that monitoring these

pressure pulsations requires

sophisticated filtering and other

signal processing that is not unlike

the requirements of monitoring a

vibration signal – particularly those

from aeroderivative gas turbines

where accelerometers are used and

extraction of desired signal features

can be very demanding.

It was not surprising, then, that

gas turbine manufacturers turned

to vibration monitoring suppliers

to meet these needs. Vibro-meter

was among the first to rise to the

challenge and offer fully integrated

combustion dynamics monitoring

with the release of our VM600

platform and its 16-channel XMC16

module.

Indeed, the deep domain expertise

of Meggitt for supplying sensors

that can survive environmental

extremes meant that vibrometer could supply not only the

necessary monitoring system, but

the associated high-temperature

dynamic pressure sensors, able to

survive in one of the most extreme

of all machinery environments:

gas turbine combustors where

conditions at the measurement

locations can approach 700°C and

250 bar.

1. Zink, John C., “Progress

continues in gas turbine NOx

control” Power Engineering. May

1, 1996. Retrieved September 19,

2021.

2. Richards, G A, and Lee, G T. “Gas

turbine combustion instability”.

US Dept of Energy. September 1,

1996. Retrieved September 19,

2021.

Combustion dynamics monitoring

is part of closed-loop control to

ensure that damaging pulsations

in low-NOx gas turbines do not

prematurely age or destroy the

combustor cans. The pulsations

occur because today’s lowNOx technologies rely on

inherently metastable combustion

conditions that burn fuel in the

leanest possible manner but can

produce an unstable flame if not

meticulously controlled

Full API 670 compliance

Within the petrochemical sector, the importance of American Petroleum

Institute standards for machinery and its associated instrumentation

cannot be overstated.

These standards are no longer considered best practice employed by the

cutting-edge few – they are so universally accepted that they are today

considered standard practice and thus widely embraced by the many.

Nowhere is this more true than with API Standard 67023 which defines the

necessary attributes of machinery protection systems.

The first edition of this standard was released in 1976 and has been so

successfully embraced that it has resulted in five successive revisions to

keep pace with industry’s changing needs: the 6th edition of the standard

is currently in preparation and is expected to be released by 2023.

Indeed, it provides such value that it has remained among the API’s bestselling standards in the more than 45 years since its introduction. Not

surprisingly, the VM600 was designed with full API 670 compliance in

mind, allowing customers in the oil & gas industries to employ the system

with the confidence that it rigorously adheres to the robust feature set

and functionality that multiple generations of users and manufacturers

have found important.

Indeed, the requirements of 670 are so well-recognized by practitioners

in all industries that it is not uncommon to find power generation

and other customers using it as the basis of their own purchasing

specifications – not just those in the petroleum industries.

3. API Standard 670 “Machinery Protection Systems”. American Petroleum

Institute. Washington, DC. November 2014.

Full API 670 compliance

Both first- and second-generation

VM600 platforms are fully

compliant with the 5th edition

of API 670. Additionally, we

participate on the API Task Force

that is currently preparing the 6th

edition to ensure we remain fully

compliant with and abreast of

industry changes as the standard

evolves.

Why a Second-Generation product?

With such a rich feature set and pedigree of innovation, it is natural to ask

why a second-generation platform was even necessary.

There are multiple reasons:

Cybersecurity

When the VM600 was originally

designed, the internet itself

was not even a decade old. The

idea that this global network

infrastructure would someday

become a remotely accessible

means to sabotage industrial

instruments and automation

systems wasn’t even part of

anyone’s thought process at the

time. But the intervening 22 years

have changed everything.

Today, cybersecurity is at the very

top of customer concerns. What

has also changed are the types

of customers concerned about

cybersecurity. For decades, the

most innovative and demanding

customers were largely in the

petroleum and oil & gas sectors.

They were often the ones with

remote facilities – such as offshore

platforms – where remote access to

data was in highest demand.

For years, they had led the way

in the defining the features and

functions required of condition

monitoring and machinery

protection platforms because their

processes were often worth millions

of dollars per hour and machinery

failures were potentially so costly.

As such, they were the ones with

the most sophisticated needs and

the deepest pockets to address

those needs.

But then, the world began to

shift as the most pressing needs

began to fall within the power

generation sector along with

corresponding expenditures to

ensure cybersecurity therein.

Where a cyberattack might be

able to bring down a single

petrochemical facility, a similar

attack could potentially bring down

major portions of the electrical

grid in a country, affecting tens of

millions of people for days.

The Northeast blackout of 20034

,

for example, left 55 million

people in the US and Canada

without power – some for as long

as two weeks. A similar event

in Europe just a few months

later left 56 million people in

Italy and Switzerland without

power5

. Moving to the southern

hemisphere, a 1999 event in Brazil

lasted more than three months and

impacted 97 million people. And

a 2012 blackout event in India7

affected more than half a billion

people for two days. The point

here is that cyber vulnerabilities

in the power generation sector

are particularly serious because

they may not necessarily

isolate themselves to a single

facility; because the generation,

transmission, and distribution

infrastructure is interconnected

via a grid, an attack can impact

huge portions of the electrical

grid for days, weeks, or months at

a time. This also impacts critical

infrastructure such as hospitals,

law enforcement, banking, water

utilities, grocery stores, petrol

stations, and other entities that

depend on electrical power to

deliver vital goods and services.

The stakes are indeed exceedingly

high.

Coupled with the realization that

an attack on the power grid had

such devastating implications,

industry began to face the reality

that cyberattacks were not just able

to exploit conventional computer

systems – they could exploit

industrial control and automation

platforms such as SCADA systems

and PLCs. In 2007, the Aurora

Generator Test8

conducted by

Idaho National Labs demonstrated

that it was possible to compromise

a protective system via the

internet and thereby destroy a

diesel generator within a mere 3

minutes. Several years later, the

Stuxnet9 worm showed the world

that an industrial cyberattack was

no longer just hypothetical – it had

actually been accomplished. Iran’s

nuclear program was sabotaged by

Stuxnet-infected PLCs, destroying

the enrichment centrifuges they

controlled by sending them into

overspeed conditions.

All of this is to underscore that

cybersecurity moved from not

even being on customers’ radar a

mere 15 years prior, to being their

number one concern by 2015.

While the VM600 had unwittingly

addressed a portion of these

concerns by entirely segregating

the protection functions from the

condition monitoring functions,

there were other aspects of the

system that represented cyber

vulnerabilities – vulnerabilities that

would require a new generation of

modules.

4 “Technical Analysis of the

August 14, 2003, Blackout: What

Happened, Why, and What Did We

Learn?”. North American Electric

Reliability Council. July 13, 2004.

Retrieved September 18, 2021.

5 “Report on the blackout in Italy on

28 September 2003” Swiss Federal

Office of Energy. November 2003. 6 “Wide Power Failure Strikes

Southern Brazil”. The New York

Times. March 12, 1999. Retrieved

September 18, 2021.

7 “India blackouts leave 700 million

without power”. The Guardian. July

31, 2012. Retrieved September 18,

2021.

8. “U.S. video shows hacker hit

on power grid”. USA Today.

September 27, 2007. Retrieved

September 18, 2021.

9. Kushner, David. “The Real

Story of Stuxnet”. ieee.org. IEEE

Spectrum. February 26, 2013.

Retrieved September 18, 2021.

Integration

While the separation between

protection and condition

monitoring in the legacy VM600

architecture was desirable from

the standpoint of cybersecurity, it

was not optimal in other respects.

In particular, because there was

no communication at all between

the condition monitoring and

protection environments, it was

cumbersome to see the status of

the protection system alarms from

within the condition monitoring

software.

Also, the same measurements

(such as overall amplitude or 1X

amplitude) were generated in each

path (protection and condition

monitoring) but could be slightly

different due to different circuitry in

different cards. Work-arounds were

available but the environments

for viewing protection and

condition monitoring statuses and

information were not truly unified.

Also, the system had to be

configured twice: once in the

protection environment and then

again in the condition monitoring

environment, without the ability

to reuse similar or identical

configuration settings from the

protection environment into the

condition monitoring environment.

Instead, the user had to manually

replicate the settings – not just

re-use the settings – such as

transducer types, full-scale values,

and even alarm setpoints.

Lastly, due to slight differences

in signal processing between the

protection hardware and condition

monitoring hardware, even

identical configurations could result

in slight discrepancies between the

timing of a protection alarm in the

MPC4 card and the emulation of

the same alarm in the XMV16 card.

While this timing was normally

not an issue, it could be more

cumbersome to create accurate

sequence-of-event reconstructions

because a protection alarm archive

had to be accessed separately

from a condition monitoring alarm

archive.

Clearly, in a next-generation

system, it would be important to

address the above issues

Component

Availability10

Users of machinery protection

systems generally expect a

lifecycle of 15-20 years for the

hardware along with a generous,

phased obsolescence period that

gives time to both plan and then

implement replacement of the

aging system.

During this time, spare parts must

still be available that maintain

hazardous area approvals and SIL

certifications. Simply substituting

newer electronic components

on circuit boards may seem like

an easy solution, but sometimes

there are no form/fit/function

replacements.

And even when there are, this

can often mean resubmittals to

approvals / certification agencies.

Eventually, the situation can

become unsustainable, even when

last-time buys of components are

secured in an attempt to meet

future demand. All of these can

represent a delicate balancing act

and finally the need to introduce a

new platform becomes inevitable.

However, manufacturers generally

view this as an opportunity to not

just replace systems, but to provide

additional functionality and value

because new customer needs have

arisen in the meantime. This has

certainly been the case with the

VM600 platform.

10. “Component Obsolescence

Management”. electronic-notes.

com. Retrieved September 19,

2021.

Deliberately

avoiding

“Rip and Replace”

One of the challenges inherent

in introducing a new platform

is to avoid “rip and replace”

requirements. No customer enjoys

being told that they must rip out

the old hardware in its entirety and

install new hardware.

This can be compounded when the

new system is so radically different

compared to its predecessor that

wiring connections cannot be

reused, panel cutout and mounting

dimensions must be modified,

different software must be used,

and even power and ventilation

requirements have changed. The

devil, as they say, is in the details.

From a manufacturer’s perspective,

“rip and replace” can also be

undesirable because it then

becomes just as easy and costeffective for customers to switch

to an entirely different supplier

as to remain with the incumbent.

For numerous reasons, it is thus

in everyone’s best interests when

the new platform represents

backwards compatibility with the

prior platform while introducing

necessary improvements to solve

the continually evolving list of

customer needs.

As vibro-meter set out to design

a second-generation version of

the VM600, we purposed that we

would not leave existing customers

stranded or inconvenienced by “rip

and replace” approaches.

but without depriving them of

the same feature and function

improvements available to

customers installing a system

for the first time. In other words,

existing customers should be

rewarded – not penalized – by the

release of a new system.

“More than 8,000

VM600 systems are

installed worldwide and

we owed it to those

customers to provide

them with a thoughtful

path forward that

allowed them to

retain as much of their

existing investment as

possible.“

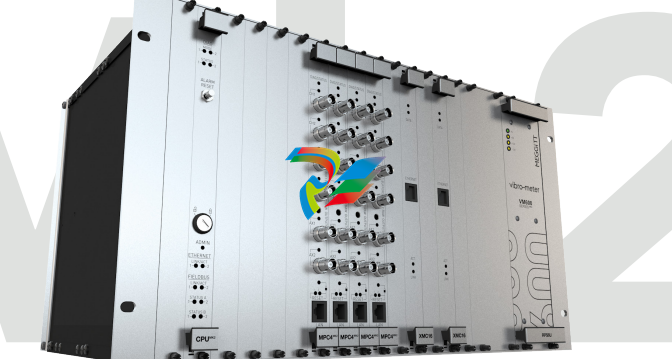

The VM600Mk2

True to our promise, it does this

without stranding our customers

and their large installed base of

more than 8,000 VM600Mk1 systems

– systems that encompass 240,000

MPC4Mk1 protection channels and

88,000 CMC/XMV/XMC condition

monitoring channels.

Because the VM600Mk2 uses the

same backplane and power

supplies as its predecessor, it is

not necessary to replace a rack in

order to upgrade modules. This

also means that existing racks

can incorporate a mix of firstgeneration (Mk1) and secondgeneration (Mk2) modules if

desired, and that Mk2 modules

can be used as spares for Mk1

modules11,

12 if desired.

In addition, the XMC and XMV12

modules have not changed

and continue to provide worldclass capabilities for dynamic

combustion monitoring and

vibration condition monitoring,

respectively; we have simply

upgraded the faceplates for

aesthetic consistency with new

modules such as the MPC4Mk2

and CPUMMk2.

11. Mk2 modules are configured

using our VibroSight PROTECT

software; Mk1 modules are

configured using our MPSx

software. Also, MPC4Mk2 modules

can

only be paired with their associated

IOC4Mk2 input/output modules and

cannot use the existing IOC4T.

12. MPC4Mk2 modules retain the

ability to share input signals with

an associated XMV16 module,

but can also provide integrated

condition monitoring functionality

and thus entirely eliminate the

need for a separate condition

monitoring module for vibration

measurements.

Our second-generation VM600 platform retains all of the

innovation inherent in the first-generation product while

addressing evolving marketplace needs.

The Second-Generation VM600 retains the same chassis and power supplies, but delivers powerful new

modules with improved functionality and cybersecurity.

1 19” EIA chassis, 6U tall, 300mm deep, 21 slots (numbered 0-20).

2 CPUMMk2 Communications and rack control module; supports redundant media with communications with plant control and

automation platforms including PLCs, DCSs, turbine controllers, local displays, and more; supported protocols include Modbus TCP,

Modbus RTU*, Profibus DP, and Profinet*. Cybersecure design to meet IEC 62443.

3 Keylock provides an extra measure of physical security in addition to password-protected access to configuration changes.

4 MPC4Mk2 Universal vibration monitoring module provides 4 channels of dynamic signal inputs and 2 channels of speed/phase or DC

inputs; provides integrated protection and condition monitoring while delivering cybersecure performance to meet IEC 62443; up to

12 modules (72 channels) per rack.

5 The MPC4Mk2 is capable of specialized measurements such as generator air gap on hydroelectric units, combustion monitoring on

gas turbines

6 SIL 2 version of MPC4Mk2 modules. Five on-board relays allow alarm and module fault (OK) status annunciation, suitable for autoshutdown applications meeting SIL 2.

7 XMV16 module can be used for condition monitoring-only applications where protection is not required; allows 16 channels of highperformance condition monitoring in a single rack slot. Ideal for balance-of-plant assets, small hydro units where protection is not

required, or for adding condition monitoring to existing third-party protection systems.

8 XMC16 module provides robust gas turbine combustion dynamics monitoring in the same chassis as vibration protection and

condition monitoring.

9 RLC16Mk2 relay expansion module provides 16 additional relays to augment the 5 relays on board each MPC4Mk2 module.

10 Proprietary ethernet communications provide all dynamic and other rack signals to VibroSight software for archival, analysis, and

visualization.

11 Simplex or redundant power supplies deliver all required power for rack modules and connected sensors.

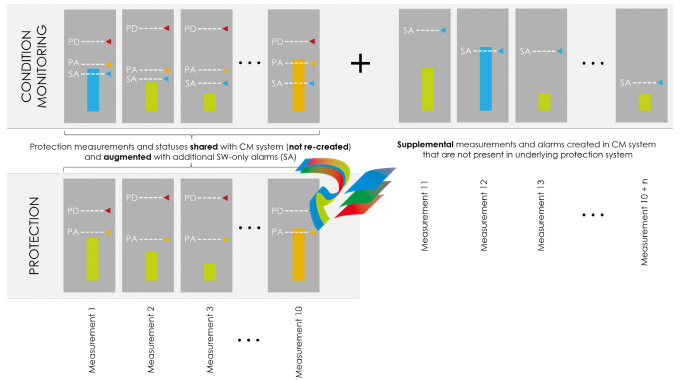

s no longer necessary to

use MPC4 cards for protection

and separate XMV1613 cards

for condition monitoring. The

functionality of the XMV16 is now

built-in to the new MPC4Mk2 cards.

Not only does this eliminate the

cost of unnecessarily redundant

hardware, it eliminates the

dissimilar-data issues inherent in

two separate signal processing

paths and alarm processing paths

that were noted in the section on

integration. Condition monitoring

can now focus on supplementary

signal processing and alarming

to augment the basic protection

system measurements – not recreating them.

This also speeds the configuration

process because the configuration

elements that are common to

both the protection and condition

monitoring systems no longer need

to be duplicated. Configuration

in the condition monitoring

environment thus adds to the basic

protection configuration. Alarms

and data are perfectly synchronized

between the two environments

and the condition monitoring

environment can be used to

visualize everything while allowing

an additional layer of alarming

for earlier warning on any desired

parameter – whether a parameter

from the underlying protection

system or a parameter created only

for use in the condition monitoring

environment.

13. When a VM600 rack is used

purely for condition monitoring,

such as when connected to a

separate machinery protection

system from another supplier, the

XMV16 module provides costeffective condition monitoring

functionality for 16 channels in a

single rack slot. MPC4Mk2 modules

and their associated machinery

protection functions are not

required.

The new MPC4Mk2 module (left) and

its companion I/O module (right)

provide integrated protection and

condition monitoring, eliminating

the need for a separate XMV16

module.

And while this integration makes

for a more powerful and efficient

VM600 platform, we have achieved

this without compromising

cybersecurity, as discussed next.

The new MPC4Mk2 module provides integrated condition monitoring functionality identical to that of a separate

XMV16 module, but in a manner that completely segregates the protective functions (black) from the condition

monitoring functions (gray). Like its predecessor, the same sensors can be shared between protective and

condition monitoring functions via the rack’s backplane.

Permanent Ethernet communication link

X

M

V16

MPC4

VM600rack

Condition

monitoring

Sensor

Machinery protection

configuration software

VibroSight condition

monitoring software

Machinery

protection

K

“Alarms and data are perfectly synchronized

between the two environments and the condition

monitoring environment can be used to visualize

everything while allowing an additional layer of

alarming.

The new MPC4Mk2 cards allow

the measurements and statuses

to be shared with VibroSight

condition monitoring software

rather than requiring that they be

re-created therein. This eliminates

the problem of measurements and

statuses that do not exactly agree

between the two environments. It

also allows the user to augment the

underlying protection system data

with supplemental measurements

and alarms. In this diagram, the

capabilities of a single channel in

the MPC4Mk2 are depicted.

The protective alert (PA) and

protective danger (PD) alarms for

each measurement are shown in

orange and red, respectively. The

MPC4Mk2 is capable of generating

10 measurements and associated

alarms from each of its four

dynamic channels.

The VibroSight condition

monitoring system can then

augment these 10 measurements

with n additional measurements as

shown by 11 through 10+n in the

diagram. In addition, software-only

alarms (SA) can be implemented

for all measurements and allow

earlier warning on any desired

parameter than is available from

the protection hardware alone. In

the diagram, a software alarm is

present on Measurement 1 even

though no hardware alarms are

present.

On Measurement 10, a hardware

alarm is present (Alert) and is

identically annunciated in both

the protection and condition

monitoring environments.

Measurement 12 is supplemental

and does not appear in the

underlying protection system at all.

Not only is the measurement

available in the software, it has

also exceeded the software alarm

threshold and thus shows as

being in an alarm state. The other

supplemental measurements are

all green, indicating that they

are below their respective alarm

thresholds.

Leave a comment

Your email address will not be published. Required fields are marked *