BENTLY Nevada 3500/60 190085-01 Precise Industrial Temperature Monitoring Solution

**Product Parameters:**

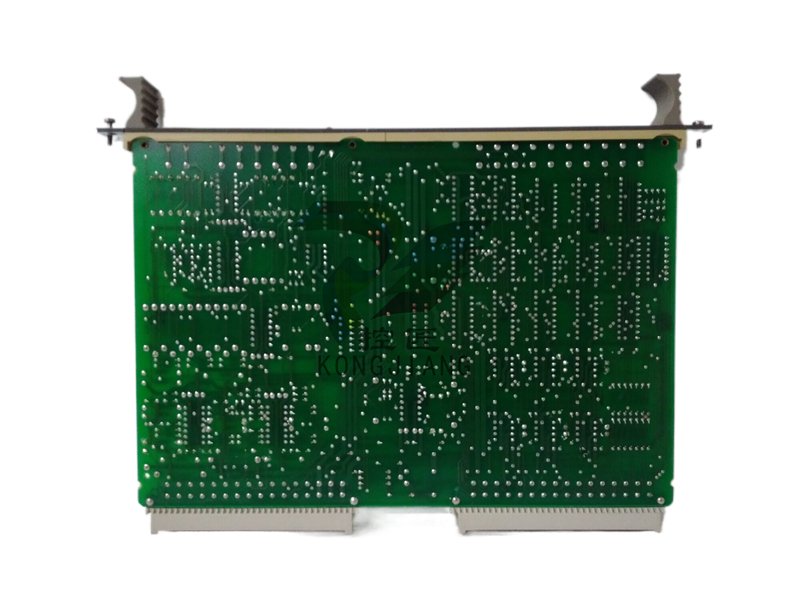

The BENTLY Nevada 3500/60 (P/N: 190085-01) is a state-of-the-art vibration monitoring system designed for real-time condition monitoring of rotating machinery. It features advanced technology for high precision and reliability, ensuring optimal performance in demanding industrial environments. With a robust design, it provides seamless integration into existing systems, enhancing operational efficiency.

**Usage Scenarios:**

Ideal for applications in power generation, oil and gas, and manufacturing, the 3500/60 excels in environments where machinery reliability is paramount. It helps in early detection of faults, reducing downtime and maintenance costs, while ensuring safety and compliance with industry standards.

**Related Models:**

For a comprehensive monitoring setup, consider related models such as BENTLY 3500/20, 3500/45, 3500/50, 3500/40M, 3500/34, and 3500/42M. Each of these models offers unique features tailored for specific monitoring needs.

**Comparison with Other Models:**

Unlike the BENTLY 3500/20, which focuses primarily on machinery protection, the 3500/60 offers enhanced capabilities for vibration analysis and diagnostics. This makes it a superior choice for users requiring detailed insights into machine performance and longevity.

The above parameters are for reference only. Please contact our technical team for precise selection.

The BENTLY Nevada 3500/60 (P/N: 190085-01) is a state-of-the-art vibration monitoring system designed for real-time condition monitoring of rotating machinery. It features advanced technology for high precision and reliability, ensuring optimal performance in demanding industrial environments. With a robust design, it provides seamless integration into existing systems, enhancing operational efficiency.

**Usage Scenarios:**

Ideal for applications in power generation, oil and gas, and manufacturing, the 3500/60 excels in environments where machinery reliability is paramount. It helps in early detection of faults, reducing downtime and maintenance costs, while ensuring safety and compliance with industry standards.

**Related Models:**

For a comprehensive monitoring setup, consider related models such as BENTLY 3500/20, 3500/45, 3500/50, 3500/40M, 3500/34, and 3500/42M. Each of these models offers unique features tailored for specific monitoring needs.

**Comparison with Other Models:**

Unlike the BENTLY 3500/20, which focuses primarily on machinery protection, the 3500/60 offers enhanced capabilities for vibration analysis and diagnostics. This makes it a superior choice for users requiring detailed insights into machine performance and longevity.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.