Custody Transfer

In the oil and gas industry, the most

critical application of flow measurement

is undertaken by companies involved

in fiscal transactions associated with

the transfer of hydrocarbon gas or

liquid from a seller to a buyer. This

transfer of liquids or gases may

take place at some remote LACT

location many miles away from the

corporate headquarters of the two

or more contracting parties. These

transactions have to be recorded

and the information made available

to the right departments for

accounting and record keeping.

The function of a Flow Computer

for Custody Transfer is four- fold:

1) Collect Raw Measurement Data

2) Calculate & Store Measured

Quantities

3) Transmit Measurement Data to a

SCADA Host

4) Execute Limited Monitoring and

Alarming Functions

Flow Measurement

Using your PLC as a cost effective controller, RTU and

Flow Computer

Product flow measurement is a basis for commerce between many oil and

gas producers, transporters and distributors. Hydrocarbon processing

plants, transmission pipelines, and many other facilities require quantitative

monitoring of fluid flow. Almost all of these measurement requirements can be

broadly classified under three main areas:

1) Custody transfer of product between two contracting parties

2) Process flow control in pump stations, process plants, etc.

3) Line balance for leak detection

The four main system components of a typical Gas or Liquid LACT site are:

1) Station Monitoring, Control, and Safety (PLC)

2) HCF Flow Measurement (Flow Computer)

3) Communications to a SCADA Host (RTU)

4) System & Measurement Data Access (PLC/Flow Computer/RTU)

ProSoft provides the solution:

AFC – Flow Calculation Modules with

Modbus RTU Capability

Meeting Industry Standards Standard Measurements

Most petroleum fluids are measured and sold on a volumetric basis. To

obtain consistent and accurate dynamic flow measurements, the flow

measurement device must convert the measured volume to an equivalent

volume referenced to a set of standard conditions acceptable to both parties.

All custody transfer transactions have to comply with two distinct categories

of enforced standards:

• Standards that define the actual algorithms and process conditions for

volumetric or mass measurement of fluids.

• Standards that define other secondary aspects of dynamic fluid

measurement like the process sampling rates, data archiving, data

security, data reporting, etc.

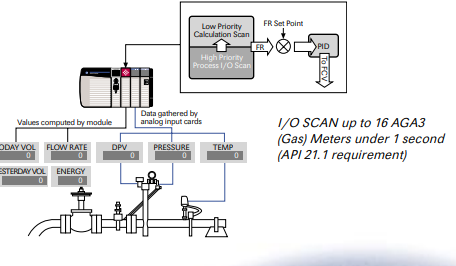

Process Flow Control

Many metering sites require pressure or fl ow control or both with pressure

override capabilities. For stable fl ow control applications, it is important

that the sampling of the process and computation of the fl ow rate be

accomplished at least twice as fast as the fastest change component of the

process. With the fast scan time of ProSoft’s AFC Module providing the

process variable to the PID block in the PLC ladder logic, stable closed

loop fl ow control can be implemented

The precision measurement

of calculations and process

inputs available utilizing

the AFC Module can more

than meet the application

requirements.

ProSoft Flow Computers

ProSoft AFC modules are in-rack Oil & Gas Flow Computers for Allen-Bradley’s

ControlLogix, SLC 500, and PLC-5 processors and Schneider Electric’s Quantum

processor. These modules support 8 or 16 meter runs for the measurement

of hydrocarbon gases using the AGA 3, 7 and 8 measurement standards. For

hydrocarbon liquid flow measurement, this solution uses API 2540 standard.

To obtain process inputs for the calculations, the module uses the process data

collected by processor’s analog I/O modules.

ProSoft’s AFC module calculates flow rates, accumulated volumes and accumulated

mass. The results of the calculations are transferred back to the processor for

use in the application ladder logic, or for transfer to a SCADA host.

Key Features • Hardware reliability • Backplane compatibility • Transient, Surge, RFI, EMI protection • Proven track record • Expandable I/O and RAM • Battery-backed RAM • Frequency Densitometer Interface • Gas/Liquid Chromatograph Interface • Field programmable • Selectable multiple measurement standards • Multiple meter runs • PLC/FC/RTU Integrated Data Base MVI71-AFC for PLC with 8 meter runs MVI46-AFC for SLC with 8 meter runs MVI56-AFC for ControlLogix with 16 meter runs PTQ-AFC for Quantum with 16 meter runs ProSoft Flow Computers ProSoft AFC modules are in-rack Oil & Gas Flow Computers for Allen-Bradley’s ControlLogix, SLC 500, and PLC-5 processors and Schneider Electric’s Quantum processor. These modules support 8 or 16 meter runs for the measurement of hydrocarbon gases using the AGA 3, 7 and 8 measurement standards. For hydrocarbon liquid flow measurement, this solution uses API 2540 standard. To obtain process inputs for the calculations, the module uses the process data collected by processor’s analog I/O modules. ProSoft’s AFC module calculates flow rates, accumulated volumes and accumulated mass. The results of the calculations are transferred back to the processor for use in the application ladder logic, or for transfer to a SCADA host. • Double Precision Math • Selectable Meter Factor Characterization • Accessible Data & System Interoperability • Data Archiving • Event Logging • Dynamic Meter Audit Scan • Local Display • Data Security • Fast Scan Times • Good Error Detection • MS Windows Based System Configuration • Site Specific System Documentation and Reports

Using Field Instrumentation

Why HART?

For many years the fi eld communication standard for process automation

equipment has been a milliamp (mA) analog current signal with a signal

range of 4-20mA. The HART (Highway Addressable Remote Transducer)

protocol extends this 4-20mA standard to enhance communication with

smart fi eld instruments. HART allows two-way digital communications to

occur without disturbing the integrity of the 4-20mA signal. HART signals

are carried over the same wiring that is typically used for 4-20mA analog

instruments. Instrumentation products equipped with the HART protocol are

used in a wide range of applications and industries, providing cost saving

benefi ts and improved performance worldwide. It has been estimated that

nearly 2 million HART installations are in existence today and include:

Rosemount, Endress & Hauser, Honeywell, and Yokagawa Transmitters.

HART Interface Modules

ProSoft Technology has a variety of HART interface modules offering

connectivity solutions for smart fi eld instrumentation that supports HART

multi-drop networks. The HART modules provide access to temperature,

pressure, and multi-variable units, as well as, full access to digital

confi guration, diagnostics, and maintenance information in each connected

transmitter.

In-Rack HART Multi-drop Modules

Modules are compatible with a number of platforms including AllenBradley’s ControlLogix, SLC 500e, PLC-5e, and CompactLogix™, as well as,

Schneider Electric’s Quantum processors.

Features

• Multi-drop Field Network

• Read / Write Data

• 4 Channels / Module

• 15 Transmitters / Channel

Stand-alone HART Gateways

The HART Gateways provide communication for four

or eight channels or multi-drop HART connectivity with

other networks including:

• Modbus

• Modbus Plus

• Modbus TCP/IP

• DF1

• Profi bus DP

• A-B Remote I/O

Honeywell DE Connectivity

In-rack or stand-alone gateway connectivity solutions for smart fi eld

instrumentation supporting Honeywell DE networks is also available

through ProSoft.

Pipeline Automation

Valve Actuators

All pipelines contain a great number of valves. These valves work like gates,

opening and closing oil or gas fl ow and can be placed every 5 to 20 miles

(8-32 km) along any given stretch of pipeline. In remote or inaccessable

areas it is important that the control of these valves are automated.

ProSoft Technology has worked together with FlowServe, makers of

Limitorque Valve Actuators, to create an interface which allows Allen-Bradley

ControlLogix, SLC, and PLC processors to easily interface with Limitorque Valve

Actuators and other Limitorque protocol compatible devices. The Limitorque

modules support the following valves:

• MX/DDC Modbus

• UEC-3-DDC Modbus

• DDC-100M I/O module

• DDC-100M fi eld unit

• Valvcon IVO (unit in multi-drop mode only)

Leave a comment

Your email address will not be published. Required fields are marked *