This Universal Instruction Manual is designed to provide the user with a single, concise, easy-touse manual that covers the key points needed for configuration, calibration, installation, and

operation of I/A Series Pressure Transmitters.

It covers all models of single variable pressure transmitters in the I/A Series family, including

absolute, gauge, and differential pressure transmitters, with FoxCom, HART, FOUNDATION

Fieldbus, or analog output electronics.

This universal manual, along with a DVD containing detailed information, is provided free of

charge with every I/A Series Pressure Transmitter, unless the purchaser requests that these two

items be omitted.

For additional detailed information about each model, including dimensional prints, parts lists,

and more detailed instructions, please refer to the standard DVD supplied or the optional paper

instruction book that is available for each model in the line.

♦ Standard Documentation Shipped with every I/A Series Pressure Transmitter

♦ A brief “Getting Started” Pocket-Sized Bulletin

♦ This Universal Instruction Manual

♦ A DVD that contains the complete documentation set for I/A Series Pressure

Transmitters

♦ When Optional Feature K1 is specified in the Model Code when the transmitter is

ordered:

A brief “Getting Started” Pocket-Sized Bulletin only is supplied

Optional Feature K1 is offered for those users who want to omit the documentation

shipped with every transmitter. This may be specified when multiple identical

transmitters are ordered and the user does not want multiple sets of documentation.

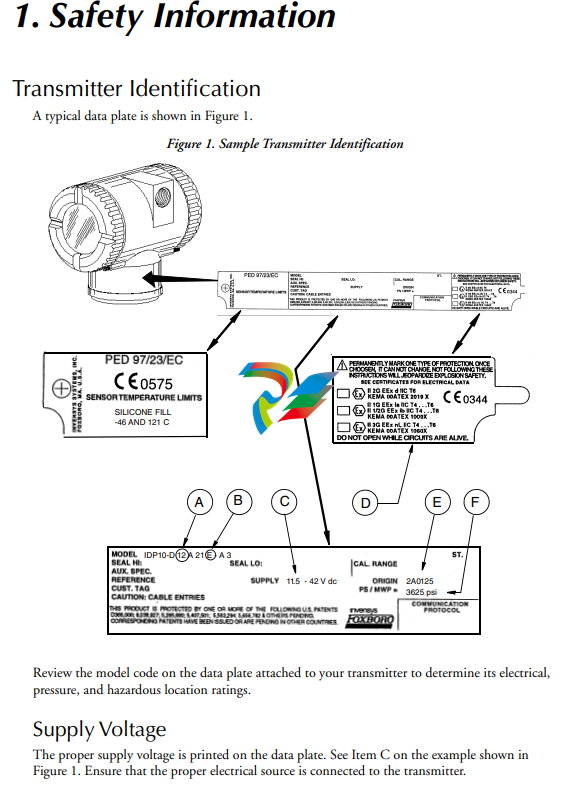

Electrical Certification Rating

The electrical safety design code is printed on the data plate as part of the model code. See Item B

on the example shown in Figure 1. See the “Product Safety Specifications” section of the

instruction pertaining to your instrument on the enclosed DVD to identify this code. The type of

protection is also marked on the data plate. See Item D on the example shown in Figure 1.

PED Certification

The PED (Harmonized Pressure Equipment Directive for the European Community)

certification is offered only with transmitters ordered with ATEX Electrical Safety Design Code

selections. Transmitters with PED certification have a CE marking on the data plate that also

carries the PED number 0496.

Pressure Rating

The maximum working pressure (PS or MWP) for the transmitter is printed on the data plate.

See Item F on the example shown in Figure 1.

The data plate of flanged level transmitters and transmitters with flanged pressure seals are

stamped with the MWP if the transmitter pressure range is the limiting factor. It is stamped

“Flange Rate” if the flange rating is the limiting factor. The MWP of the flanged seal is stamped

on the seal data plate. See Figure 2.

Figure 2. Sample Seal Data Plate

When using transmitters with threaded, in-line saddle weld, or sanitary pressure seals, compare

the MWP of the transmitter on the transmitter data plate and the MWP of the seals on the seals

data plates and use the lesser value as the system MWP.

The MWP on the seal data plates may not be given at your process temperature. Use the

following information and industry standards as required to determine the actual pressure limits

for your application.

MODEL CODE: PSFPS-A2S0E313B MWP: 275 psig at 100°F

NOTICE: BREAKING CONNECTIONS VOIDS WARRANTY

BE SURE FILL FLUID CAN MIX SAFELY WITH PROCESS HIGH SIDE SEAL

HIGH SIDE FLUID, DC200, 10 cSt SILICONE TEMP RANGE -40 TO +450°F

PROCESS WETTED MATERIAL 316 SS

essure Seal PSFLT

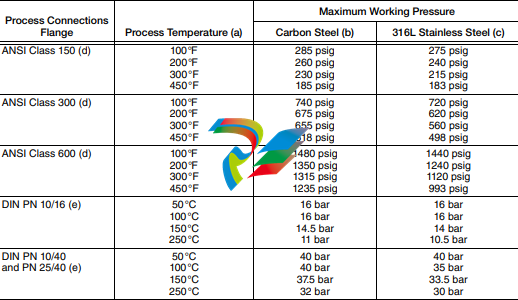

Table 1. Pressure Seal PSFLT Pressure Limits

a. Flange temperature/pressure ratings only; seal temperature ratings may be lower; refer to Table 8

b. ASME/ANSI Material Group 1.1; linear interpolation acceptable

c. ASME/ANSI Material Group 2.2; linear interpolation acceptable

d. ANSI flanges per ASME/ANSI B16.5-1988.

e. DIN flanges per BS4504.

Pressure Seals PSFPS and PSFES

Table 2. Pressure Seal PSFPS and PSFES Pressure Limits

Pressure Seals PSSCR and PSSCT

The maximum working pressure of the seal process connection varies with the clamping device

used. Refer to Tri-Clover Tri-Clamp standards to determine the pressure limits of the clamping

system that you are using.

PSSSR and PSSST (Sanitary Tank Spud) Seals

The maximum working pressure of mini tank spud seal is 1.55 MPa at 120°C (225 psi at 250°F).

That of the standard tank spud seal is 1.38 MPa at 120°C (200 psi at 250°F).

Origin Code

The origin code identifies the area of manufacture and the year and week of manufacture. See

Item E on the example shown in Figure 1. In the example, 2A means the product was

manufactured in the Measurement and Instrument Division, 01 identifies the year of

manufacture as 2001, and 25, the week of manufacture in that year.

Operating Temperature Limits

The operating temperature limits of the electronics are -40°C and +85°C (-40°F and +185°F).

The limits are -40°C and +75°C (-40°F and +167°F) for IAP10, IGP10, IGP25, and IGP50

Transmitters with ATEX flameproof certification. Ensure that the transmitter is operated within

this range.

The sensor body operating temperature limits are determined by the sensor fill fluid. The cover

material, sensor diaphragm material and fill fluid are specified by two characters in the model

code on the data plate. See Item A on the example shown in Figure 1. Also see Table 5 and

Table 6 to interpret this part of the code and Table 7 to determine the sensor body temperature

limits. In the example IDP10-D12A21E-A3, the number 12 identifies the fill fluid in Table 5 as

silicone. Table 7 identifies silicone as having temperature limits of -46 and +121°C (-50 and

+250°F).

The diaphragm material code is found in the pressure seal model number which is located on the

pressure seal. See following example:

The housing material is 316 ss.

The gasket is provided by the user.

Pressure Seals PSSCT

The housing material is 316 ss.

The diaphragm material is 316L ss.

The gasket is provided by the user.

Pressure Seals PSSSR and PSSST

The housing material is 316 ss.

The diaphragm material is 316L ss.

The gasket material is EPDM.

Warnings

General Warning

! WARNING

1. Transmitters must be installed to meet all applicable local installation regulations,

such as hazardous location requirements, electrical wiring codes, and mechanical

piping codes. Persons involved in the installation must be trained in these code

requirements to ensure that the installation takes maximum advantage of the safety

features designed into the transmitter.

2. A plug is supplied with each transmitter with 1/2 NPT conduit connection. It is

intended to provide moisture ingress protection of the unused housing conduit entry.

The plug must be wrench tight to achieve this level of protection. Thread sealant is

required. Explosion-proof applications may require a certified plug.

Housings with M20 / PG 13.5 threaded conduit connections are provided with an

ATEX certified plug. Thread sealant is required to provide moisture ingress

protection.

ATEX Warnings

! WARNING

Apparatus marked as Category 1 equipment and used in hazardous areas requiring

this category must be installed in such a way that, even in the event of rare incidents,

the versions with an aluminum alloy enclosure can not be an ignition source due to

impact and friction

Install ATEX certified transmitters in accordance with the requirements of standard

EN 60079-14.

! WARNING

To install a transmitter labeled with multiple approvals, select and permanently mark

the certification label in the tick block to distinguish the installed approval type from

the unused approval types. Once installed, the transmitter cannot be reinstalled using

any other approval type. Not following these instructions will jeopardize explosion

safety.

On IGPxx and IAPxx Transmitters with IECEx certification, the maximum constructional gap

(Ic) is less than that required by IEC 60079-1:2003 as detailed in the table below:

Explosionproof/Flameproof and Enclosure Warning

! WARNING

1. To prevent possible explosion and to maintain explosionproof/flameproof and dustignitionproof protection, plug unused openings with a certified metal pipe plug. For

1/2 NPT connections, both the plug and conduit must be engaged a minimum of five

full threads. For M20 and PG 13.5 connections, the certified plug provided and the

conduit must be engaged a minimum of seven full threads.

2. The threaded housing covers must be installed. Turn covers to seat O-ring into the

housing and then continue to hand tighten until the cover contacts the housing

metal-to-metal.

3. If the electronics housing is removed for any reason, it must be hand tightened

fully. Then engage the set screw until it bottoms out and back it off 1/8th turn. Fill

the set screw recess with red lacquer (Foxboro Part Number X0180GS or equivalent).

The housing then may be rotated up to one full turn in a counterclockwise direction

for optimum access to adjustments.

Intrinsically Safe and Type n Warning

! WARNING

Since live maintenance is not specified, to prevent ignition of flammable atmospheres,

disconnect power before servicing unless the area is certified to be nonhazardous.

Type n Warning

! WARNING

On transmitters certified for ATEX protection n, CSA Class I, Division 2, or FM

nonincendive for Class I, Division 2, the threaded housing covers must be installed.

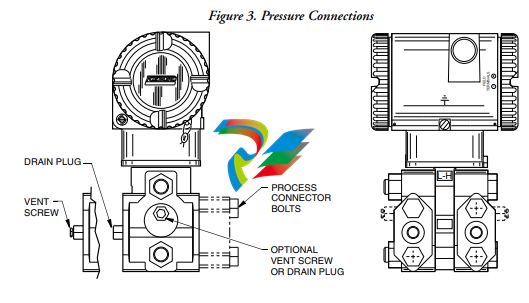

Pressure Warnings

! WARNING

When installing your transmitter, tighten process connector bolts to a torque of

61 N•m (45 ft•lb) and drain plugs and optional vent screws to 20 N•m (15 ft•lb). See

Figure 3.

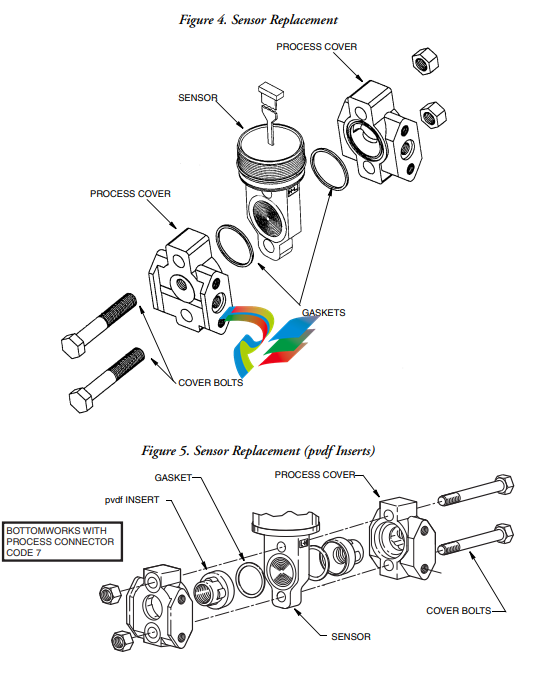

If a sensor is replaced or process covers are rotated for venting, replace the gaskets and

torque cover bolts (see Figures 4 and 5) to 100 N•m (75 ft•lb) in several even

increments. Torque values are 66 N•m (50 ft•lb) when optional 316 ss bolts are

specified (option B1). A pressure test is required. Perform a hydrostatic test with a

liquid following proper hydrostatic test procedures. Pressure test the process cover

assembly by applying a hydrostatic pressure of 150% of the maximum static and

overrange pressure rating to both sides of the process cover/sensor assembly

simultaneously through the process connections. Hold pressure for one minute. There

should be no leakage of the test fluid through the gaskets.

Process Fluid Warning

! WARNING

If process containing parts are to be disassembled:

1. Make sure that process fluid is not under pressure or at high temperature.

2. Take proper precautions concerning leakage or spillage of any toxic or otherwise

dangerous fluid. Follow any Material Safety Data Sheet (MSDS)

recommendations.

Seal or Sensor Fill Fluid Warning

! WARNING

Even though the volume of fill fluid is small, be sure that the fill fluid can mix safely

with the process fluid.

Parts Replacement Warning

! WARNING

This product contains components that have critical safety characteristics. Do not

substitute components. Replace components only with identical factory supplied

components. Component substitution may impair the electrical safety of this

equipment and its suitability for use in hazardous locations.

EU Declaration of Conformity

We, Manufacturer:

Invensys Systems, Inc.

38 Neponset Ave.

Foxboro, Massachusetts 02035

U.S.A.

declare under our sole responsibility that the

I/A Series Pressure Transmitters IGP, IAP, IDP, IPI, IMV

are in conformity with the protection requirements of Council Directives:

♦ 2004/108/EC on the approximation of the laws of the Member States relating to

Electromagnetic Compatibility

♦ 94/9/EC on the approximation of the laws of the Member States concerning

equipment and protective systems intended for use in potentially explosive

atmospheres

♦ 2014/68/EU on the approximation of the laws of the Member States concerning

pressure equipment

The basis on which Conformity is being declared:

♦ EN 61326-1:2006, Electrical equipment for measurement, control and laboratory use

EMC requirements, Class A emission limits, and immunity requirements according to

Table 2 for Industrial locations.

♦ EN50014 1997 A1 1999 A2 1999 Electrical apparatus for potentially explosive

atmospheres ‘General Requirements’.

♦ EN50018 2000 Electrical apparatus for potentially explosive atmospheres

‘Flameproof enclosures ‘d”.

♦ EN50020 1995 Electrical apparatus for potentially explosive atmospheres ‘Intrinsic

safety ‘I”.

♦ EN50021 1999 Electrical apparatus for potentially explosive atmospheres ‘Type of

protection ‘n”.

♦ EN50284 1999 Special requirements for construction, test and marking of electrical

apparatus of group II Category 1 G.

♦ EN 50281-1-1 1999 Electrical apparatus for use in the presence of combustible dust.

♦ EN 60079-15 2003 Electrical apparatus for explosive gas atmospheres – Part 15:

Electrical apparatus with type of protection “n”

For compliance with ATEX, products are in accordance with EC Type Examination Certificates

KEMA 00ATEX 1060X, KEMA 00ATEX 2019X and KEMA 00ATEX 1009X, issued by KEMA

Quality B.V., Ultrechtseweg 310, 6812 AR Arnhem, The Netherlands, Notified Body number

0344, and with EC Type Examination Certificates SIRA 04ATEX1349, SIRA 04ATEX2335X,

SIRA 06ATEX4056X, SIRA 06ATEX2055X, and SIRA 06ATEX4019X, issued by Sira

Certification Service, Rake Lane, Eccleston, Chester, CH4 9JN, England, Notified Body number

0518. The authorized markings for each certificate are shown below. The actual ATEX markings

on the product vary according to model code. Refer to Product Specification Sheet and marking

on product for details pertaining to individual model codes.

KEMA 00ATEX1060X II 3 G EEx nL IIC T4 … T6

II 1 GD EEx nL IIC T4 … T6 T 135°C

KEMA 00ATEX1009X II 1 G EEx ia IIC T4 … T6

II 1/2 G EEx ib IIC T4 … T6

II 1 GD EEx ia IIC T4 … T6 T 135°C

II 1/2 GD EEx ib IIC T4 … T6 T 135°C

KEMA 00ATEX2019X II 2 G EEx d IIC T6

II 2 GD EEx d IIC T6 T 85°C

SIRA 04ATEX1349 II 2 GD EEx d IIC T6 T 85°C

SIRA 04ATEX2335X II 1G EEx ia IIC T4

SIRA 06ATEX4056X II 3 GD EEx nL IIC T4

SIRA 06ATEX2055X II 1 GD EEx ia IIC T4

SIRA 06ATEX4019X II 3 G EEx nL IIC T4

For the Pressure Equipment Directive, conformity is based on a certificate issued by DNV GL,

Veritasveien 1, 1322 HOVIK, Norway, Notified Body number 0496, based on Maximum

Working Pressure (MWP). Conformity Assessment Module “H” is applied for Models IGP, IAP,

IMV and IDP where the MWP is greater than 200 bar. The applicable design standard is

IEC/EN 61010-1

. Installation

! CAUTION

To avoid damage to the transmitter sensor, do not use any impact devices, such as an

impact wrench or stamping device, on the transmitter.

NOTE

1. The transmitter should be mounted so that any moisture condensing or draining

into the field wiring compartment can exit through one of the two threaded

conduit connections.

2. Use a suitable thread sealant on all connections.

3. If the transmitter is not installed in the vertical position, readjust zero output to

eliminate the position zero effect.

Mechanical Installation

Differential Pressure Transmitter

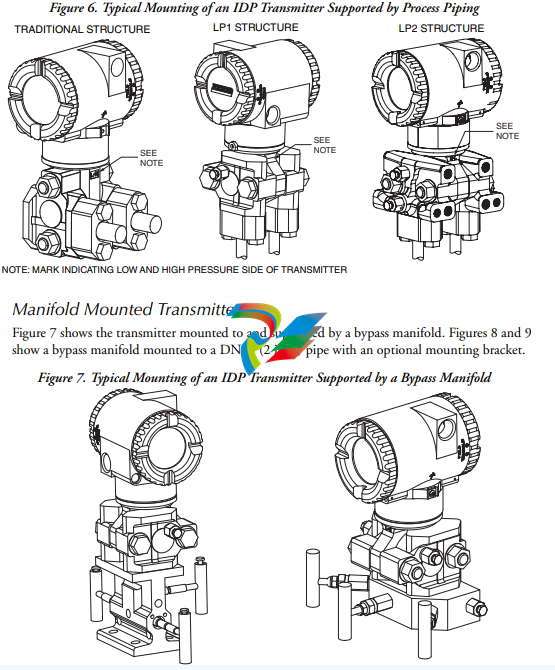

The IDP10, IDP25, and IDP50 differential pressure transmitters can be supported by the process

piping (Figure 6), on a bypass manifold (Figures 7 through 10), or mounted to a vertical or

horizontal pipe or surface using an optional mounting bracket (Figures 11 through 16). For

dimensional information, refer to DP 020-446.

NOTE

1. The IDP25 and IDP50 transmitters are only available in the Traditional Structure

at this time.

2. If the transmitter is not installed in the vertical position, readjust zero output to

eliminate the position zero effect.

3. When pvdf inserts (structure codes 78/79) are used, the process connection must

be made directly to the pvdf inserts in the Hi and Lo side process covers.

4. The transmitter should be mounted so that any moisture condensing or draining

into the field wiring compartment can exit through one of the two threaded

conduit connections.

Process-Mounted Transmitter

Figure 6 shows the transmitter mounted to and supported by the process piping

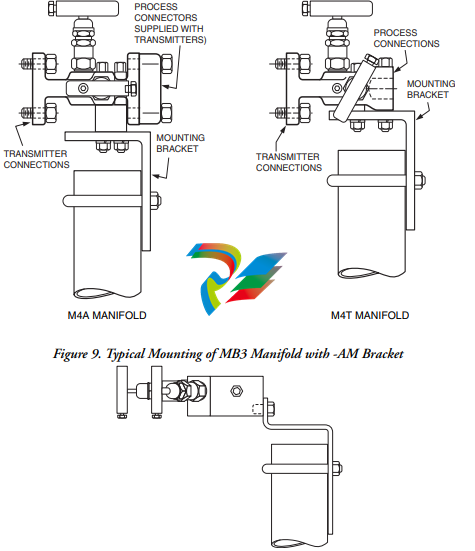

Figure 8. Typical Mounting of M4A and M4T Manifold with -AM Bracket

Pipe- or Surface-Mounted Transmitter

To mount the transmitter to a pipe or surface, use the Standard Mounting Bracket Set (Model

Code Option -M1 or -M2) or Universal Bracket Mounting Set (Model Code Option -M3).

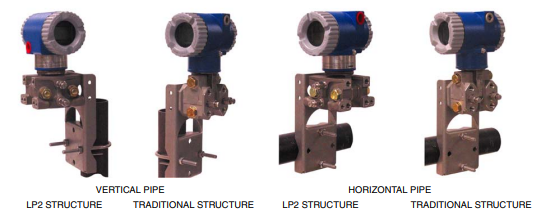

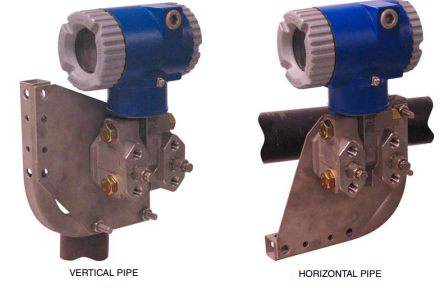

Standard Mounting Bracket

The transmitter (with either traditional or LP2 low-profile structures) can be mounted to a

vertical or horizontal, DN 50 or 2-in pipe using a standard bracket. See Figure 11 for details and

Figure 12 for examples of different situations. Secure the mounting bracket to the transmitter

using the four screws provided. Mount the bracket to the pipe. To mount to a horizontal pipe,

turn the U-bolt 90° from the position shown in Figure 11. The mounting bracket can also be

used for wall mounting by securing the bracket to a wall using the U-bolt mounting holes.

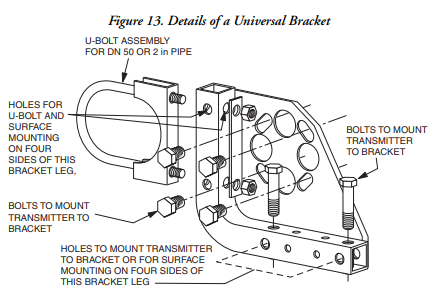

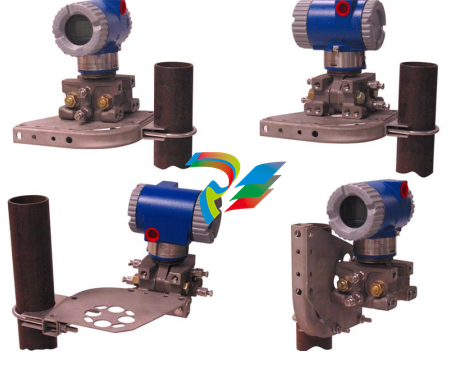

Universal Mounting Bracket

The transmitter (with either traditional or LP2 low-profile structure) can be mounted in a myriad

of positions to a vertical or horizontal, DN 50 or 2-in pipe using a universal bracket. See

Figure 13 for details of a universal bracket and Figure 14 through Figure 16 for examples of

different mounting situations. Secure the mounting bracket to the transmitter using the two long

or four short screws provided. Mount the bracket to the pipe. The mounting bracket can also be

used for wall mounting by securing the bracket to a wall using the U-bolt mounting holes.

Figure 14. Mounting a Transmitter with Traditional Structure Using a Universal Bracket

Figure 15. Vertical Pipe Mounting a Transmitter with LP2 Structure Using a Universal Bracket

Leave a comment

Your email address will not be published. Required fields are marked *