This manual describes how to install, setup, and operate a

CAS200. Included are six chapters and a glossary of terms.

Each chapter covers a different aspect of the alarm scanner

and may apply to different users. The following describes

the chapters and their purpose.

• Chapter 1: System Overview provides a component

list and summary of features for the CAS200 series

alarm scanners.

• Chapter 2: Installation provides detailed

instructions on installing the CAS200 and its

peripherals.

• Chapter 3: Using the CAS200 provides an overview

of operator displays used for system monitoring and

job selection.

• Chapter 4: Setup provides detailed descriptions of all

menus and parameters for scanner setup.

• Chapter 5: Troubleshooting and

Reconfiguration provides some basic guidelines for

solving operational problems and provides procedures

for changing some of the hardware options (e.g.

installing special input resistors and changing EIA/

TIA-232 to EIA/TIA-485).

• Chapter 6: Linear Scaling Examples provides

three examples where linear scaling is used.

• Chapter 7: Specifications lists detailed

specifications of the scanner and optional components.

Product Features

The CAS200 is a modular monitoring system with 16

analog inputs. It can function as a stand-alone system; the

CAS200 1/8 DIN front panel has a Vacuum Fluorescent

Display (VFD) and touch keypad for local display and local

parameter entry. You can also use it as the key element in

a computer supervised data acquisition system; the

CAS200 can be locally or remotely controlled via an EIA/

TIA-232 or EIA/TIA-485 serial communications interface.

Features include:

Direct Connection of Mixed Thermocouple Sensors:

Connect most thermocouples to the scanner with no

hardware modifications. Thermocouple inputs feature

reference junction compensation, linearization, process

variable offset calibration to correct for sensor

inaccuracies, detection of broken, shorted or reversed

thermocouples, and a choice of Fahrenheit or Celsius

display.

Automatic Scaling for Linear Analog Inputs: The

CAS200 series automatically scales linear inputs used with

industrial process sensors. Enter two points and all input

values are automatically scaled in your units. Scaling

resistors must be installed.

Flexible Alarm Outputs: Independently set high/low

process alarms and a high/low deviation band alarm for

each channel. Alarms can activate a digital output by

themselves, or they can be grouped with other alarms to

activate an output.

Alarm Outputs: You can set high/low deviation and high/

low process alarm setpoints to operate digital outputs as

latched or unlatched functions.

Global Alarm Output: When any alarm is triggered, the

global alarm output is also triggered, and it stays on until

you acknowledge it.

CPU Watchdog: The CAS200 series CPU watchdog timer

output notifies you of system failure. Use it to hold a relay

closed while the system is running, so you are notified if the

microprocessor shuts down.

Front Panel or Computer Operation: Set up and run

the scanner from the front panel or from a local or remote

computer. Watlow Anafaze offers WatView, a Windows®

compatible Human Machine Interface (HMI) software

package that includes data logging and graphing features

in addition to process monitoring and parameter setup

screens.

Multiple Job Storage: Store up to eight jobs in protected

memory, and access them locally by entering a single job

number or remotely via digital inputs. Each job is a set of

alarm conditions.

Pulse Counter Input: Use the pulse counter input for

precise monitoring of motor or belt speed.

System Diagram

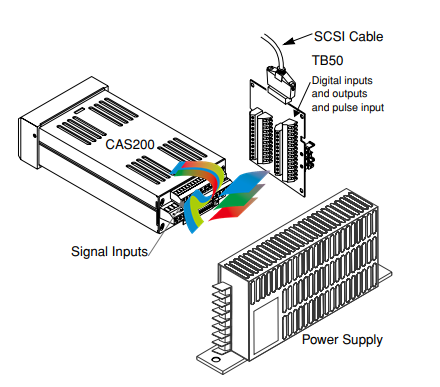

The illustration below shows how the parts of the CAS200

are connected. When unpacking your system, use the

diagram and parts list below to ensure all parts have been

shipped. Please don’t hesitate to call Watlow Anafaze if you

have problems with your shipment, or if any CAS200

components are missing or damaged.

Figure 1.1 System Components

• CAS200 Scanner

• Mounting Kit

• TB50 Terminal Board

• 50-Pin SCSI Cable

• DC Power Supply

Mounting Scanner Components

Install the scanner in a location free from excessive heat

(>50°C), dust, and unauthorized handling.

Electromagnetic and radio frequency interference can

induce noise on sensor wiring. Select locations for the CAS

200 and TB50 such that wiring can be routed clear of

sources of interference such as high voltage wires, power

switching devices and motors.

∫

WARNING! To reduce the risk of fire or electric shock, install

CAS200 in a controlled environment, relatively

free of contaminants.

Safety

Watlow Anafaze has made efforts to ensure the reliability

and safety of the CAS200 and to recommend safe uses in

systems applications. Note that in any application failures

can occur.

Good engineering practices, electrical codes, and insurance

regulations require that you use independent external

safety devices to prevent potentially dangerous or unsafe

conditions. Assume that the CAS200 can fail or that other

unexpected conditions can occur.

Install high or low temperature protection in systems

where an overtemperature or undertemperature fault

condition could present a fire hazard or other hazard.

Failure to install temperature control protection where a

potential hazard exists could result in damage to

equipment and property, and injury to personnel.

For additional process safety, program a computer or other

host device to automatically reload your desired operating

parameters after a power failure. However, this safety

feature does not eliminate the need for other external,

independent safety devices in dangerous conditions.

The CAS200 should never be used as a safety

shutdown device. It should only be used with

other approved independent safety shutdown

devices.

Contact Watlow Anafaze immediately if you have any

questions about system safety or system operation.

This chapter describes how to install the CAS200 series

scanner and its peripherals. Installation of the scanner

involves the following procedures:

• Determining the best location for the scanner

• Mounting the scanner and TB50

• Power Connection

• Input Wiring

• Communications Wiring (EIA/TIA-232 or EIA/TIA485)

• Output Wiring

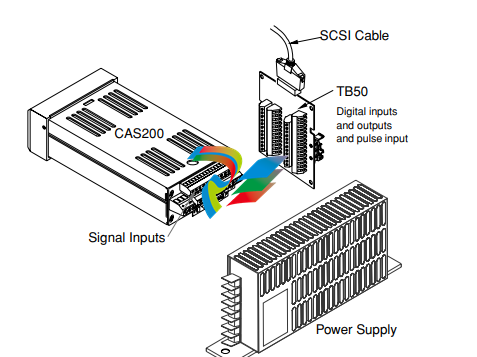

Typical Installation

The illustrations below show typical installations of the

scanner with the TB50 terminal block. Observe the

illustration below to determine potential space

requirements.

We recommend that you read this entire chapter first

before beginning the installation procedure. This will help

you to carefully plan and assess the installation.

Figure 2.1 System Components

Safety

∫

WARNING! Ensure that power has been shut off to your entire

process before you begin installation of the

scanner

Watlow Anafaze has made every effort to ensure the

reliability and safety of this product. In addition, we have

provided recommendations that will allow you to safely

install and maintain this scanner.

∫

WARNING! In any application, failures can occur. These

failures can result in full control output (100%

power), or the occurrence of other output failures

which can cause damage to the scanner, or to the

equipment or process connected to the scanner.

Therefore, always follow good engineering

practices, electrical codes, and insurance

regulations when installing and operating this

equipment.

External Safety Devices

External safety devices should be used to prevent

potentially dangerous and unsafe conditions upon

equipment failure. Always assume that this device can fail

with outputs full-On, or full-Off, by the occurrence of an

unexpected external condition.

∫

WARNING! Always install high or low temperature protection

in installations where an overtemperature or

undertemperature fault will present a potential

hazard. Failure to install external protection

devices where hazards exist can result in damage

to equipment, property, or human life.

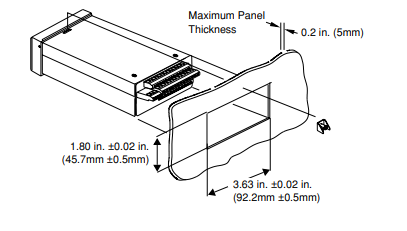

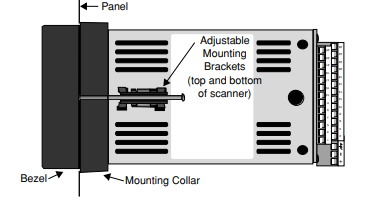

Mounting

We recommend you mount the scanner in a panel not more

than 0.2 inches thick.

∫

WARNING! To reduce the risk of fire or electric shock, install

the CAS200 in a controlled environment,

relatively free of contaminants.

Location

Install the scanner in a location free from excessive (>50°C)

heat, dust, and unauthorized handling.

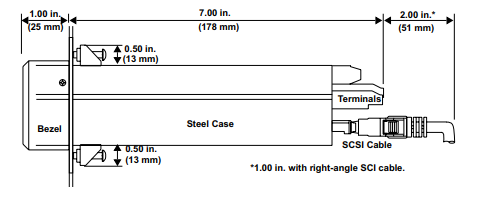

Ensure there is enough clearance for mounting brackets,

terminal blocks, and cable and wire connections; the

scanner extends 7.0 in. behind the panel face and the screw

brackets extend 0.5 in. above and below it. Allow an

additional 1 to 3 inches for the SCSI cable.

Figure 2.2 Clearance Recommendations

Other Tools:

You will also need these tools:

• Phillips head screwdriver

• Flathead screwdriver for wiring

• Multimeter

Mounting the Scanner

Mount the scanner before you mount the TB50 or do any

wiring. The scanner’s placement affects placement and

wiring considerations for the other components of your

system.

You receive one of two types of mounting brackets with

your scanner, the mini-bracket or the collar bracket. Refer

to the corresponding sections below for instructions.

Steps Using the Mini-Bracket

1. Cut a hole in the panel to the dimensions shown in the

illustration below. To do this, use a punch, nibbler, or

jigsaw, and file the edges of the hole.

2. Insert the scanner into the hole through the front of

the panel.

3. Screw the top and bottom clips in place: insert the

clip’s lip into the cutout in the scanner’s metal housing

just behind the front panel. Tighten the screws.

4. If you expect much panel vibration, use a rear support

for the scanner and its interconnecting cables.

Figure 2.3 Mounting with the Mini-Bracket

Steps Using the Collar Bracket

Installing and mounting requires access to the back of the

panel.

NOTE! Removing the scanner chassis from its case

makes mounting easier.

1. Make a panel cutout. Refer to Figure 2.3 on page 11 for

dimensions of the cutout.

2. Slide the scanner into the panel cutout.

3. Slide the mounting collar over the back of the scanner,

making sure the mounting screw indentations face

toward the back of the scanner.

4. Loosen the mounting bracket screws enough to allow

for the mounting collar and panel thickness. Place

each mounting bracket into the mounting slots (head

of the screw facing the back of the scanner). Push each

bracket backward then to the side to secure it to the

scanner case.

5. Make sure the case is seated properly. Tighten the

installation screws firmly against the mounting collar

to secure the unit. Ensure that the end of the mounting screws fit into the indentations on the mounting

collar.

Figure 2.4 Mounting with the Collar Bracket

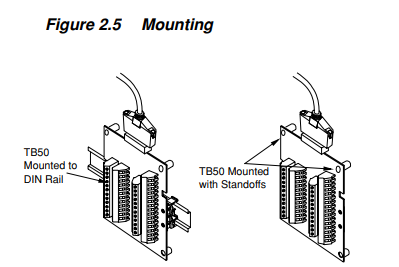

Mounting the TB50

There are two ways you can mount the TB50, by using the

pre-installed DIN rail mounting brackets provided or by

using the plastic standoffs. Follow the procedures for each

to mount the board.

Leave a comment

Your email address will not be published. Required fields are marked *